PRODUCT CENTER

XING TAL LONG

Recommended Products

XTL sintyron High Temperature Alumina Ceramic roller Thermocouple Protection Tubes for furance

Alumina ceramic tubes are made of high-purity alumina powder through a process of shaping and sintering at high temperatures. Known for their exceptional mechanical strength, chemical resistance, and thermal stability, alumina ceramic tubes are widely used in various industrial applications. These tubes have a smooth surface finish and high dimensional accuracy, making them ideal for use in environments where corrosion, wear, and high temperatures are common.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

XTL sintyron High Temperature Alumina Ceramic roller Thermocouple Protection Tubes for furance

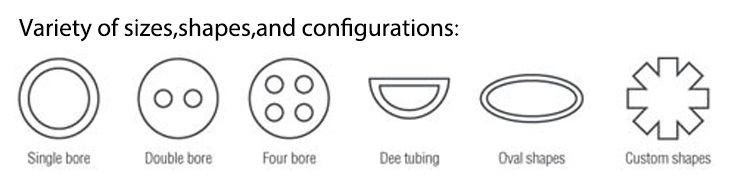

We can do OEM and OBM according to your drawing and requires:

We can do OEM and OBM according to your drawing and requires:

Product description:

Alumina tubes are made of alumina (Al2O3) ceramics. As a fine ceramic material, alumina is widely used in many industries. Alumina tubes have excellent electrical insulation, high chemical resistance and low thermal expansion, and these ceramic tubes are widely used in industrial ovens and machines. High purity alumina materials are ideal for the manufacture of alumina components for CVD, ion implantation, lithography and semiconductor manufacturing.

Alumina tubes are made of alumina (Al2O3) ceramics. As a fine ceramic material, alumina is widely used in many industries. Alumina tubes have excellent electrical insulation, high chemical resistance and low thermal expansion, and these ceramic tubes are widely used in industrial ovens and machines. High purity alumina materials are ideal for the manufacture of alumina components for CVD, ion implantation, lithography and semiconductor manufacturing.

Specification :

ceramic alumina tube , alumina content 95% - 99.7%,White or Ivory ,Wear-resisting and acidproof alkali corrosion , High temperature (1600-1700 degree centigrade). Good chemical stability,high insulation, strong adsorption capacity, is a nice electrical insulation and wear-resisting material.

| Composition | AL95 | AL99 |

| AL2O3 Content | 97% | 99.80% |

| Color | White | Ivory |

| Tensile | 30 Kpsi | 32 Kpsi |

| Flexural | 55 Kpsi | 60 Kpsi |

| Compressive | 300 Kpsi | 330 Kpsi |

| Density | 3.7 g/cc | 3.92 g/cc |

| Hardness | 13.8 HV, Gpa | 18 HV, Gpa |

| Thermal Conductivity | 25 W/(m K) | 32 W/(m K) |

| C.O.T.E. | 77 In / In°C (x10^7) | 78 In / In°C (x10^7) |

| Working Temperature | 1500 °C | 1750 °C |

| Dielectric Constant | 9.5 | 9.8 |

| Volume Resistivity | >10^14 Ohm-cm | >10^15 Ohm-cm |

| Dielectric Strength | 16 KV/mm | 20 KV/mm |

The main molding methods of alumina ceramic products are: dry pressing, isostatic pressing, injection molding and casting, different product shapes, sizes, complex modeling and precision products need different molding methods. Alumina ceramic products sintered at high temperature can only be processed using diamond grinding process.

Feature of alumina ceramic tubes:

1.High hardness

2.high wear resistance

3.corrosion resistance

4.high temperature resistance

5.corrosion resistance and bioinertness

Application of alumina ceramic tubes:

1. Parts for manufacturing CVD, ion implantation, lithography and semiconductor parts.

2. In traditional industries, alumina ceramics are the ideal choice for products such as spray tubes, gas nozzles and insulators.

3. It is used as a material in industrial furnaces because of its ability to maintain hardness at high temperatures.

4. Used as a high temperature thermocouple protector, 5. Due to its high corrosion resistance, used as a material in the chemical industry.

Advantages of alumina ceramic tubes:

Compared to metals and polymers, alumina tubes are preferred in extreme conditions. Its general characteristics and durability make it an important part of products that require durability but require low maintenance. This long-lasting quality makes it the first choice for producing long life products.

Other forms of piping made of various polymers or metals may need to be cleaned or replaced frequently. Once the alumina ceramic tubes are installed, they are guaranteed to last for many years. The chemical resistance and non-conductivity of alumina tubes make them perfect protectants and insulators.

Company Information: