PRODUCT CENTER

XING TAL LONG

Recommended Products

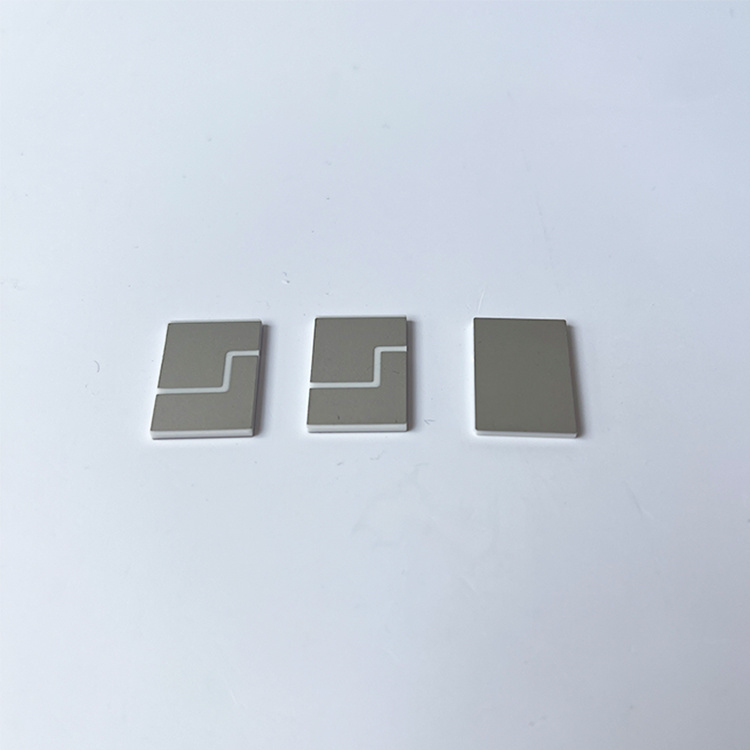

XTL sintyron metallized beryllium oxide ceramic sheet/beo ceramic discs

Metallized beryllium oxide substrate is a specialized material used in electronics and other high-tech applications. Beryllium oxide is known for its excellent thermal conductivity and resistance to thermal shock, making it ideal for use in environments with extreme temperature fluctuations. The substrate is coated with a thin layer of metal, typically copper or aluminum, to enhance its electrical conductivity and facilitate the attachment of electronic components. This metallized layer also provides a stable surface for soldering and bonding processes. The combination of beryllium oxide's unique properties and the added benefits of metallization make this substrate a popular choice for applications such as power electronics, microwave devices, and semiconductor packaging. Its high performance and reliability make it a valuable material for demanding electronic systems.

Contact usProducts Center

XTL sintyron metallized beryllium oxide ceramic sheet/beo ceramic discs

| Performance For Industrial Ceramic | |||

| Item | test condition | units | index |

| Beryllium oxide BeO | / | / | ≥99 |

| volume density | / | g/cm | ≥2.85 |

| air tightness | / | / | pass |

| Fluid permeability | / | / | pass |

| Flexural Strength | / | mpa | ≥170 |

| coefficient of expansion | 215-500°C | X10/°C | (7-8.5)x10 |

| Thermal Conductivity | 100°C | W/m.K | ≥170 |

| 25°C | W/m.K | ≥250 | |

| permittivity | 1MHz20°C | 6.5-7.5 | |

| 10GHz20°C | 6.5-7.5 | ||

| loss tangent | 1MHz20°C | X10 | ≤4x104 |

| 10GHz20°C | X10 | ≤8x104 | |

| volume resistivity | 25°C | Ω.cm | ≥1014 |

| disruptive strength | KV/mm | ≥25 | |

| chemical stability | 1:9HCI | Mg/cm | ≤0.2 |

beryllium oxide ceramic has always been an important part of electronic devices in national defense equipment. In the selection of structural materials for the production of electronic components in China, with the development of electronic components to high power and miniaturization, oxidized ceramic is characterized by good thermal conductivity, high folding strength, low dielectric constant, low dielectric loss, high insulation performance and welding and sealing with metal. It is widely used in military communications, remote sensing and telemetry electronic countermeasures, photoelectric technology and other fields, and has become an indispensable and important raw material for the production of microelectronic devices (thick and thin film circuits, high-power semiconductor devices) and photoelectric devices (infrared detection and imaging).

Specifications

- Blood glucose meters for diabetics

- Gas lasers for DNA and tissue analysis

- Confocal and wide field florescence microscopy equipment

- Portable defibrillators

- Telecom Infrastructure

Product Description

Beryllium oxide (BeO) ceramic materials are in high demand due to their superior performance at high temperatures along with a thermal conductivity second only to diamond among insulating materials.We offer solutions to any component that must provide high thermal conductivity in conjunction with electrical resistivity. Building on our unique combination of materials forming, firing and fabrication technologies, we are rapidly expanding our product portfolio to provide the next generation of beryllia ceramic materials.BeO Ceramic Materials are ideal in thermal management applications when the following design considerations are critical:

- The physical size of the device or the enclosure is reduced.

- The device is exposed to high ambient temperatures

- Airflow or liquid cooling is not practical or prohibitively expensive

- Ideal materials for heat sinks in electronic circuits

- Ideal crucible material for melting and sintering operations providing superior performance at very high temperatures.

Typical Beryllium Oxide Ceramics Applications

Medical:

- Blood glucose meters for diabetics

- Gas lasers for DNA and tissue analysis

- Confocal and wide field florescence microscopy equipment

- Portable defibrillators

- Telecom Infrastructure

- Transistors and terminations in wireless system

Lasers

- High end laser diodes for commercial systems

- Industrial laser metal cutting and marking equipment

- Long range fiber optic transmission

Semiconductor handling equipment

- End-effectors and arm components

- Wafer chucks

- Crucibles for high temperature melting

Energy

- Oil and gas exploration

- In situ X-ray analysis for down-hole drilling

- Concentrating photovoltaic (CPV) systems

- Optoelectronics

- Transmitters, receivers, modulators and switches

- Power amplifiers and drivers

Military and Aerospace

- Radar modules

- Guidance modules

- Microwave and millimeter-wave communications modules

Wireless Communications

- Point-to-point and point-to-multi point radios

- Satellite communication modules

Product details

FAQ

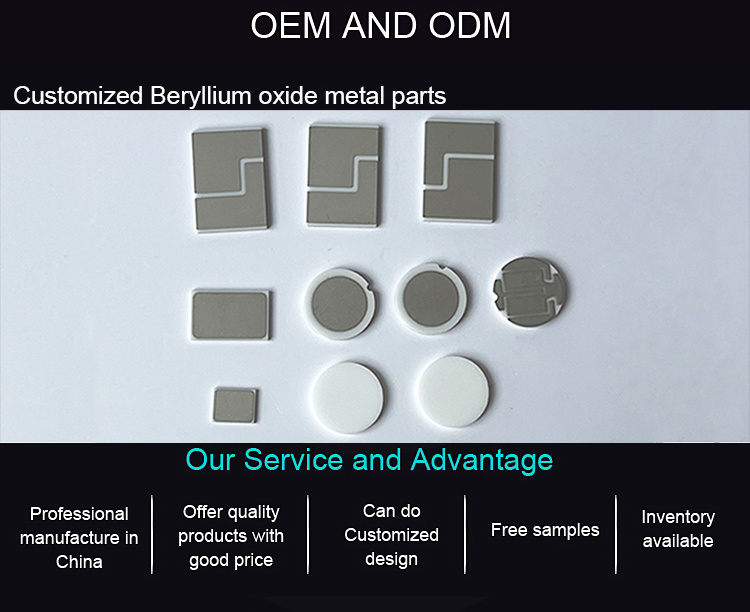

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.