PRODUCT CENTER

XING TAL LONG

Recommended Products

XTL Sintyron PBN Pyrolytic Boron Nitride Ceramic Composite Heater

The process of manufacturing Pyrolytic Boron Nitride Ceramic Composite Heater involves mixing PBN powder with other ceramic materials to enhance its mechanical strength and thermal conductivity. The mixture is then molded into the desired shape and sintered at high temperatures to create a dense and uniform ceramic composite material. The final product is a high-performance heater that can operate at temperatures up to 2000°C with minimal thermal expansion and excellent thermal shock resistance.

Contact usProducts Center

XTL Sintyron PBN Pyrolytic Boron Nitride Ceramic Composite Heater

Pyrolytic Boron Nitride Ceramic Composite Heater is commonly used in various industrial applications, such as semiconductor processing, aerospace, and research laboratories. It is often utilized as a heating element in vacuum furnaces, chemical vapor deposition (CVD) systems, and high-temperature reactors due to its ability to provide precise and uniform heating in extreme environments. Additionally, Pyrolytic Boron Nitride Ceramic Composite Heater is also used in analytical instrumentation, medical devices, and other high-tech industries where precise temperature control and reliability are essential.

Application:

MBE heaters; MOCVD, PECVD heaters

Characteristics:

High purity(>99.999%)

Chemical inertness, Acid, alkali, salt and organic reagent resistance

Uniform heating, the difference in temperature between +3 degree at 1000 degree.

Can be made to complicated shape

The temperature can rise up to 1700'C with high speed(in non-active condition and vacuum)

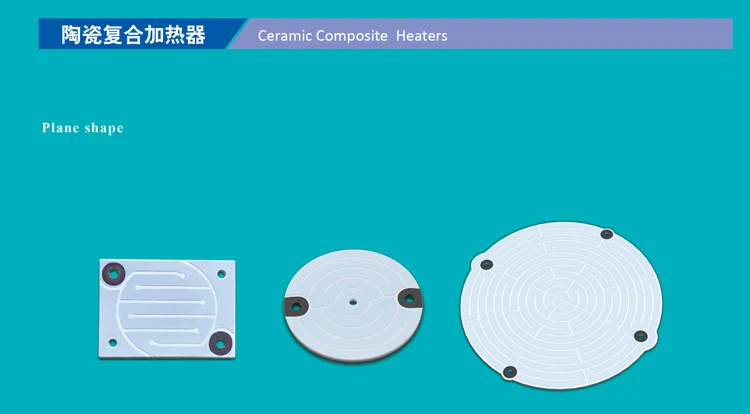

Ceramic heaters

1:No hydrogen embrittlement

2:Integrated structure, convenient maintenance

3:The conductor is covered by PBN, eliminate short-circuit

4:Easy cleaning

5:Uniform and stable heating

6:Excellent corrosion resistance at high temperature

7:Withstands repeated rapid heating and cooling ,200C/min

8:Keep its original shape under external force

PBN Properties

| Property | Unit | Value | |

| Density | g/cm3 | 1.95-2.22 | |

| Lattice Constant | m | a:2.5x10-10 c:6.8x10-10 | |

| Tensile Strength | MPa | 80 | |

| Bend Strength | MPa | 243 | |

| ThermalConductivity | (200C) | W/m·K | 82.3(a) 2.6(c) |

| (900C) | W/m·K | 55.3(a) 2.8(c) | |

| CTE | mm/mm/K | 2.0x10(a) | |

| Dielectric Constant | 10GHz | / | 5.2(a) 3.8(c) |

| Dielectric Strength | kV/mm | 56 | |

| Resistivity | Q·cm | 10 15 | |

| TotalMetallic Impurities | ppm | <10 | |

Packing

As a ceramic material, boron nitride is quite fragile in a lot of cases. Our PBN/AG heater is carefully handled to minimize damage during storage and transportation. Suitable outer boxes and inner cushioning materials are used for PBN products, vacuum packing is also engaged for some of the parts.

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.