PRODUCT CENTER

XING TAL LONG

Recommended Products

Fire Assay Flux for Gold Analysis

In conclusion, the choice of flux is critical for the accurate analysis of gold in ores and concentrates. A well-formulated flux can help to ensure that the gold is efficiently recovered and that the results of the assay are reliable. By using a suitable flux and following proper assay procedures, analysts can obtain precise and reproducible measurements of gold content in their samples.

Contact usProducts Center

Fire Assay Flux for Gold Analysis

Fire assay is a widely used method for the analysis of gold in ores and concentrates. In order to obtain accurate results, it is essential to use a suitable flux during the assay process. The flux serves several important functions, including promoting the fusion of the sample, facilitating the separation of gold from other elements, and ensuring that the gold is completely recovered.

There are several different types of fluxes that can be used for gold analysis, but one of the most commonly used fluxes is a mixture of lead oxide, borax, and silica. This flux is known for its ability to form a stable slag during the assay process, which helps to prevent the loss of gold and other precious metals.

Lead oxide is added to the flux because it acts as a collector for the gold particles, helping to concentrate the precious metal in the resulting slag. Borax is used as a fluxing agent, helping to lower the melting point of the sample and promote the fusion of the sample components. Silica is added to the flux to help control the viscosity of the slag and improve the separation of the gold from other elements.

In addition to these main components, other additives such as flour or litharge may also be included in the flux to help reduce the formation of lead buttons and improve the recovery of gold. The exact composition of the flux may vary depending on the specific requirements of the assay, but in general, a typical flux for gold analysis may contain lead oxide (30-40%), borax (20-30%), silica (20-30%), and other additives (10-20%).

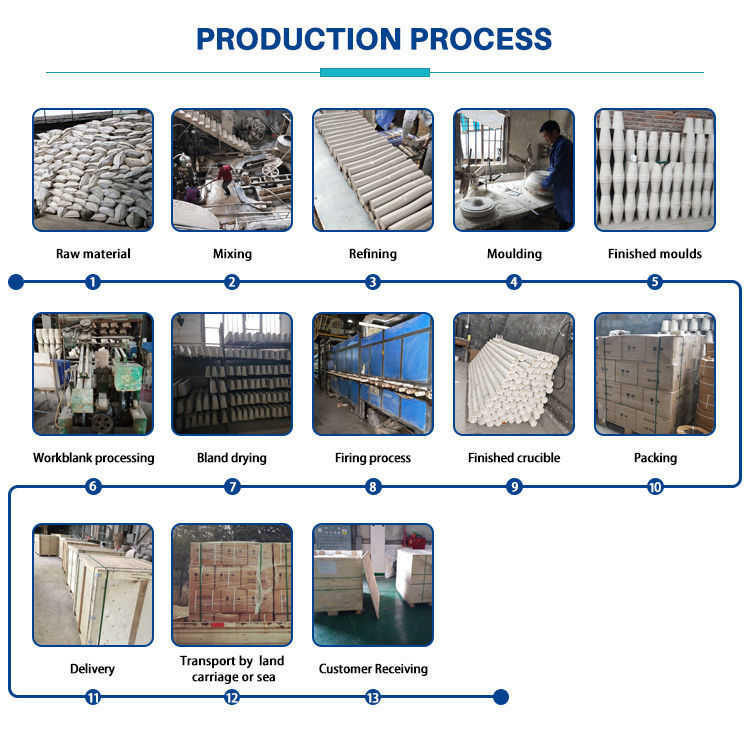

During the fire assay process, the flux is mixed with the sample in a crucible and heated to a high temperature in a furnace. As the sample melts, the flux helps to form a slag that contains the gold and other precious metals, while the impurities are left behind in the crucible. The slag is then poured off and the gold is recovered by cupellation or other methods.

The raw materials are certified for the use of fire test flow, the main ones are litharge or lead oxide with SGS certified amounts of gold <1 ppb and Silver<1 ppm. In addition is used Borax anhydrous, sodium carbonate, silicon oxide, fluorite, and other elements to order of each customer.

For each batch that is made for a given customer, a counter sample is left, which is kept for three months.

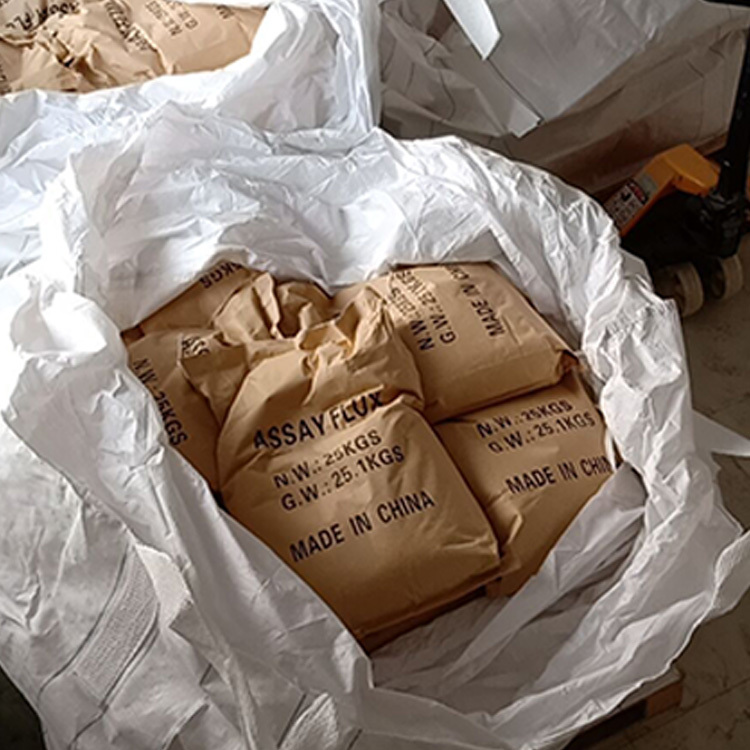

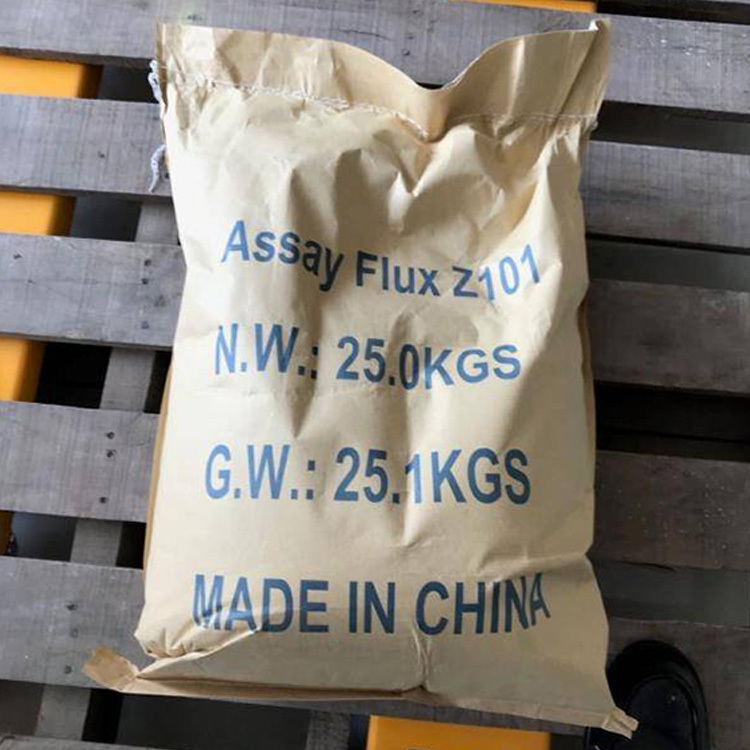

The fire assay flux is packed in 25kg bags, 25kg iron drum or as customers’ requirement.

Technical specification for core material litharge:

| SiO2, % ≥ 99 | Residue (Mesh 125) 0.09 |

| Al2O3,% ≤ 0.0012 | |

| Fe2O3,% ≤ 0.007 | |

| CaO & MgO,% ≤ 0.0009 |

-

Packing detail:25kgs/woven bag, 50Kg/woven bag, 50Kg/iron drum, 1000Kg/big bag,

all packing PE bag inside.

-

Port

-

Qingdao Shanghai

-