PRODUCT CENTER

XING TAL LONG

Recommended Products

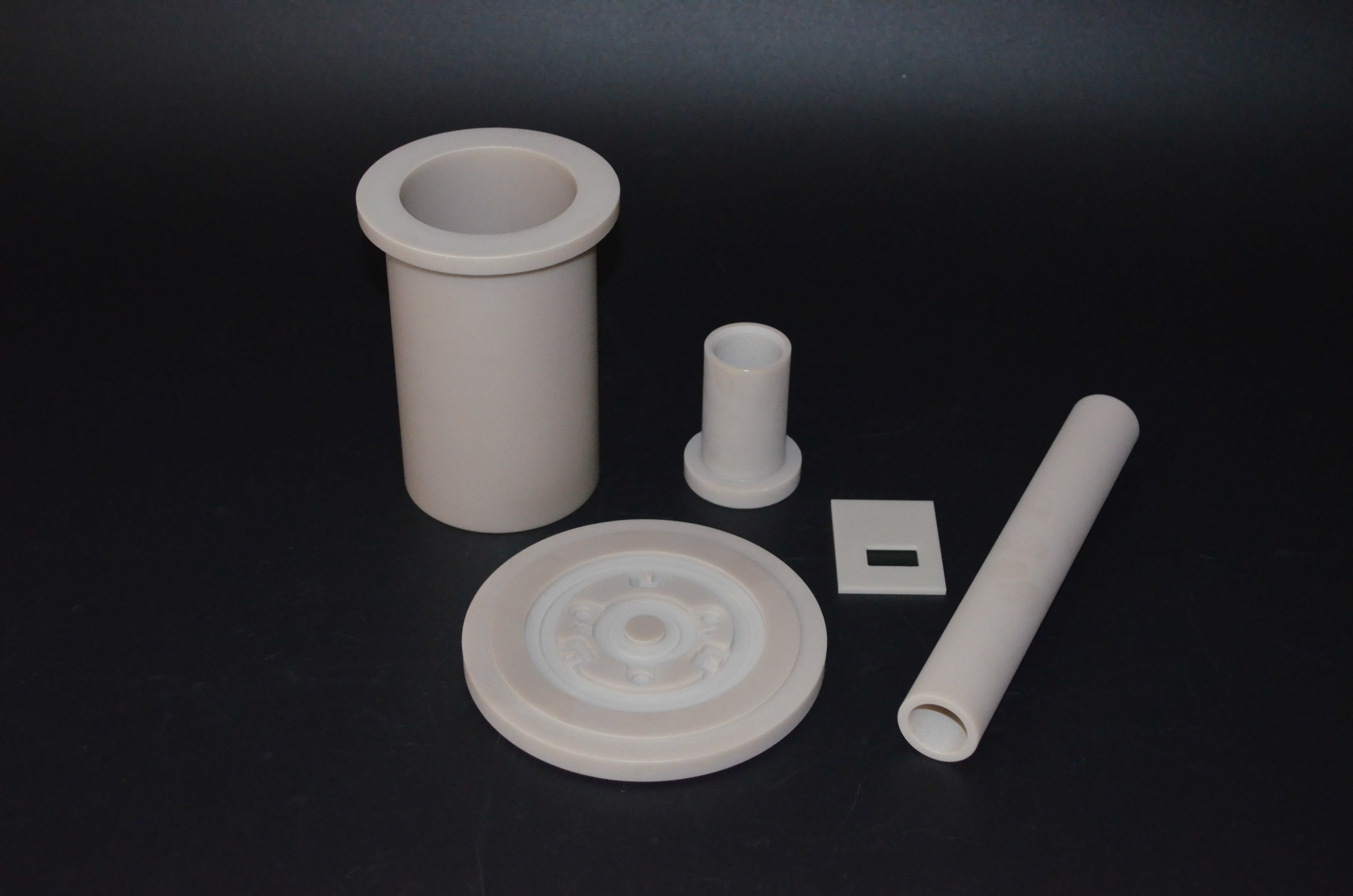

XTL sintyron Customized high precision high thermal conductive aluminum nitride ceramic crucible

Aluminum nitride ceramics (AlN ceramics) has excellent thermal conductivity (5-10 times of alumina ceramics), low dielectric constant and dielectric loss, reliable insulation properties, excellent mechanical properties, non-toxic, high temperature resistance, chemical corrosion resistance, thermal expansion coefficient and silicon similar, widely used in communication equipment, high brightness LED, power electronic equipment and other industries.

Contact usProducts Center

XTL sintyron Customized high precision high thermal conductive aluminum nitride ceramic crucible

An aluminum nitride crucible is a type of container made from aluminum nitride, a compound that is known for its high thermal conductivity, high strength, and resistance to corrosion. These crucibles are commonly used in high-temperature applications, such as melting and casting of metals, as well as in the production of semiconductors and other electronic components.

Parameters:

Aluminum nitride tubes can be customized in terms of length, diameter, and wall thickness to meet specific requirements. They can be manufactured with a smooth surface finish to ensure tight tolerances and optimal performance. The material can also be sintered to achieve a high density and uniform microstructure for improved mechanical properties.

Main properties of aluminum nitride crucible

1. High mechanical strength and hardness

2. Good electrical insulation

3. Low dielectric constant and dielectric loss

4. Thermal expansion similar to silicon

5. High thermal conductivity

6. Excellent corrosion resistance

Applications:

Aluminum nitride ceramics can be used as containers for vacuum evaporation and metal smelting, especially suitable for vacuum evaporation crucibles for aluminum, because aluminum nitride ceramics are heated in a vacuum of low vapor pressure and will not pollute aluminum even if decomposed. In semiconductor industry, aluminum nitride crucible is used instead of quartz crucible to synthesize arsenide, which can completely eliminate Si's pollution to GaAs and obtain high purity products.

Performance For Industrial Ceramic

|

Item |

Unit |

Our standard | |

|

Appearance |

Color |

- |

Gray / Beige |

|

|

Microstructure |

- |

Dense and fine grain |

|

|

SurfaceRoughness() |

μm |

0.46 |

|

|

Warpage |

‰ |

<2.5 |

|

Physical |

Water Absorption |

% |

0.061 |

|

|

Vickers Hardness |

GPa |

12 |

|

|

Young Modulus |

GPa |

330 |

|

|

VolumeDensity |

g/Cm3 |

≥3.24 |

|

|

BendingStrength |

[3-point Method]MPa |

>350 |

|

Thermal |

@20℃ThermalConductivity |

[@20℃]W/m·k |

≥170 |

|

|

CoefficientofLinear Expansion |

RT-300℃]10-6mm/℃ |

4.6 |

|

Electrical |

Volume Resistance |

Ω·cm |

1.5×1013 |

|

|

[@1MHz] Dielectric Constant |

- |

10.6 |

|

|

[@1MHz] Dielectric Loss |

- |

4.6×10-4 |

|

|

Dielectric Strength |

(KV/mm) |

≥20 |

Advantages:

There are several advantages to using aluminum nitride tubes in various applications:

1. High thermal conductivity: Aluminum nitride tubes have a thermal conductivity that is significantly higher than other ceramic materials, such as alumina and zirconia. This allows for efficient heat dissipation and thermal management in electronic components.

2. High electrical resistivity: Aluminum nitride tubes have a high electrical resistivity, which makes them suitable for use in insulating applications where electrical insulation is required.

3. Good mechanical strength: Aluminum nitride tubes have a high hardness and good mechanical strength, which makes them resistant to wear and damage. This allows for long-term reliability and durability in harsh operating conditions.

Related products

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.