PRODUCT CENTER

XING TAL LONG

Recommended Products

XTL Sintyron Advanced Industrial Sealed Electrical Connectors for feedthrough in Vacuum Equipments

Sealed electrical connectors play a critical role in providing a reliable and leak-free feedthrough for electrical signals and power in vacuum equipment. By selecting the appropriate type of connector and ensuring it meets the necessary requirements for vacuum compatibility, temperature resistance, chemical compatibility, and electrical performance, engineers can ensure the reliable operation of their vacuum systems.

Contact usProducts Center

XTL Sintyron Advanced Industrial Sealed Electrical Connectors for feedthrough in Vacuum Equipments

In vacuum equipment, sealed electrical connectors play a crucial role in providing a reliable and leak-free

feedthrough for electrical signals and power. These connectors are designed to withstand the extreme

conditions present inside vacuum chambers, such as high temperatures, high vacuum levels, and exposure

to various gases and chemicals.

There are several types of sealed electrical connectors commonly used in vacuum equipment, including:

1. Hermetic connectors: These connectors are designed to provide a completely sealed and leak-free

connection between the vacuum chamber and external electrical equipment. They are typically made

from materials such as stainless steel, ceramic, or glass, and are welded or brazed to ensure a hermetic seal.

2. Feedthrough connectors: These connectors are designed to pass electrical signals or power through

the vacuum chamber walls without compromising the vacuum integrity. They are typically made from

materials such as copper, aluminum, or stainless steel, and are sealed using O-rings, glass seals, or elastomers.

3. High-voltage connectors: These connectors are specifically designed to handle high voltages and currents

in vacuum environments. They are often insulated with materials such as ceramic or epoxy to prevent electrical

arcing and ensure safe operation.

4. Coaxial connectors: These connectors are used for transmitting high-frequency signals in vacuum equipment.

They consist of an inner conductor surrounded by a dielectric material and an outer conductor, which are sealed

to prevent signal loss and interference.

Sealed electrical connectors for feedthrough in vacuum equipment must meet stringent requirements to ensure

reliable operation. Some key considerations when selecting sealed electrical connectors for vacuum applications include:

1. Vacuum compatibility: The connectors must be able to withstand high vacuum levels without outgassing or

leaking, which can compromise the vacuum integrity of the system.

2. Temperature resistance: The connectors must be able to withstand high temperatures inside the vacuum

chamber without degrading or failing.

3. Chemical compatibility: The connectors must be resistant to corrosive gases and chemicals present in the

vacuum environment to prevent degradation and ensure long-term reliability.

4. Electrical performance: The connectors must provide low resistance, low capacitance, and low inductance

to ensure efficient transmission of electrical signals and power.

Our metallizing processes could be customized according to clients’ requirements.

|

Major components |

95% 96%.99 Al2O3 |

|||

|

|

Density |

g/cm3 |

3.6 |

|

|

Material properties |

Water absorption |

% |

O |

|

|

Sintering temperature |

°C |

1600-1800 |

||

|

Physical properties |

Hardness |

HV |

1500 |

|

|

Flexural strength |

Kgf/cm2 |

3000 |

||

|

Compressive strength |

Kgf/cm2 |

25000 |

||

|

Fracture toughness |

Map.m3/2 |

3-4 |

||

|

|

Maximum temperature |

°C |

1800 |

|

|

Thermal properties |

Coefficient of thermal expansion |

/°C |

8*10-6 |

|

|

|

Heat shock |

T(°C) |

220 |

|

|

Thermal conductivity |

W/m.k(25-300°C) |

25 14 |

||

|

|

|

20°C |

|

>1012 |

|

Volume resistivity |

100°C |

>.cm |

1012-1013 |

|

|

Electrical Characteristics |

|

300°C |

>1010 |

|

|

Insulation breakdown strength |

KV/mm |

18 |

||

|

dielectric constant |

100MHz(E) |

9.5 |

||

|

Joining types: |

|

Ceramic + Mo/Mn Metallized + plating Ni |

|

Ceramic + Mo/Mn Metallized + plating Ag |

|

Ceramic + Mo/Mn Metallized + plating Au |

|

Ceramic + printing Ag |

|

* Special types are available according to customer's drawings or samples. |

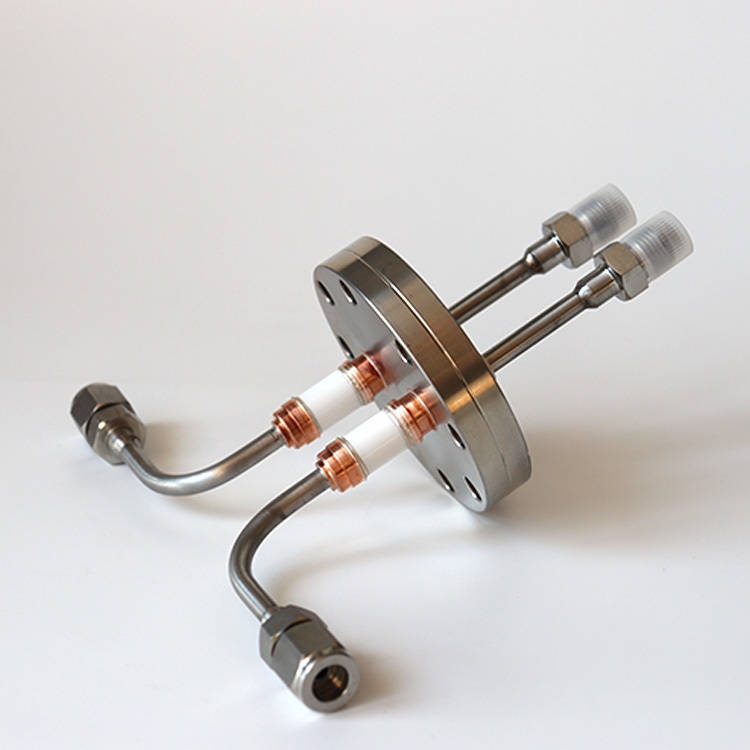

Material :

· Insulator-Glazed Ceramic 96% Al2O3 (white)

· Feedthrugh – Nickel, Kovar, Copper

· Weld Sheath/Flange-Nickel, Kovar, 304 Stainless Steel

Connection type:

Ceramic products + molybdenum/manganese metallization + nickel plating

Ceramic products + molybdenum/manganese metallization + silver plating

Ceramic products + molybdenum/manganese metallization + gold plating

The vacuum electrode flange is usually composed of the following structures:

1. Contact: used to connect two flanges, usually made of copper or stainless steel.

2. Flange: a flat plate mounted on the contact, between which a vacuum sealing chamber is formed.

3. Bolts: Components for fixing and connecting flanges.

4, insulation gasket: the insulation material installed between the bolt and the flange to ensure the insulation performance of the flange.

5, conductive plug: used for grounding at non-standard connections to ensure the electrical safety of the system.

Features:

· Feedthroughs are custom made to specifications that determined by the electrical, temperature, and environmental condition requirements.

· Standard parts are available

Characteristics

· High Abrasion Resistance

· High Mechanical Strength

· Pressures over 10,000 PSI

· High Temperature Usage

· Low Dielectric Loss

· Mass Spectrometer Leak Tested

· High Chemical Stability

· High conductivity

· High temperature resistance

· Corrosion resistance

APPLICATION:

Through the core insulator

Power switch

Insulating disc

TWT

Insulating rings and cylinders

Vacuum interrupter

heading

viewport

High power socket

Power pipe

Dust collector product

The X-ray tube

Company Information

FAQ

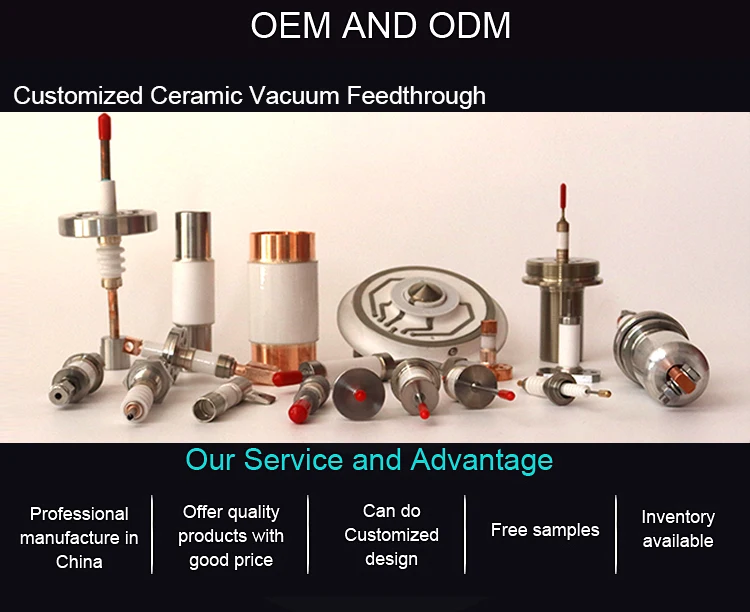

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.