PRODUCT CENTER

XING TAL LONG

Recommended Products

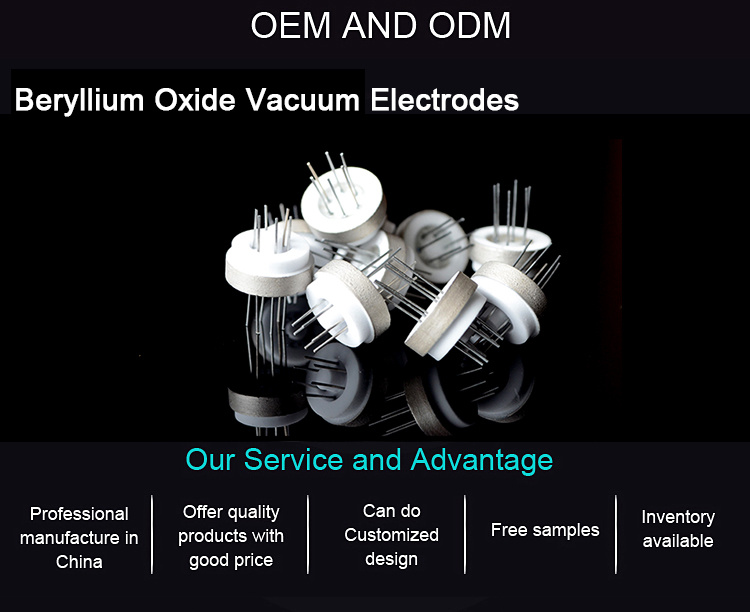

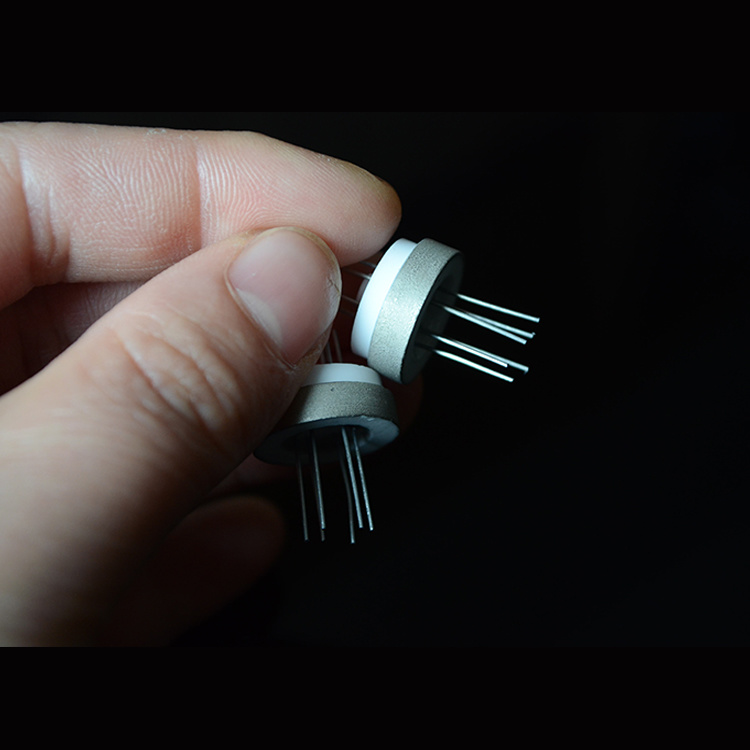

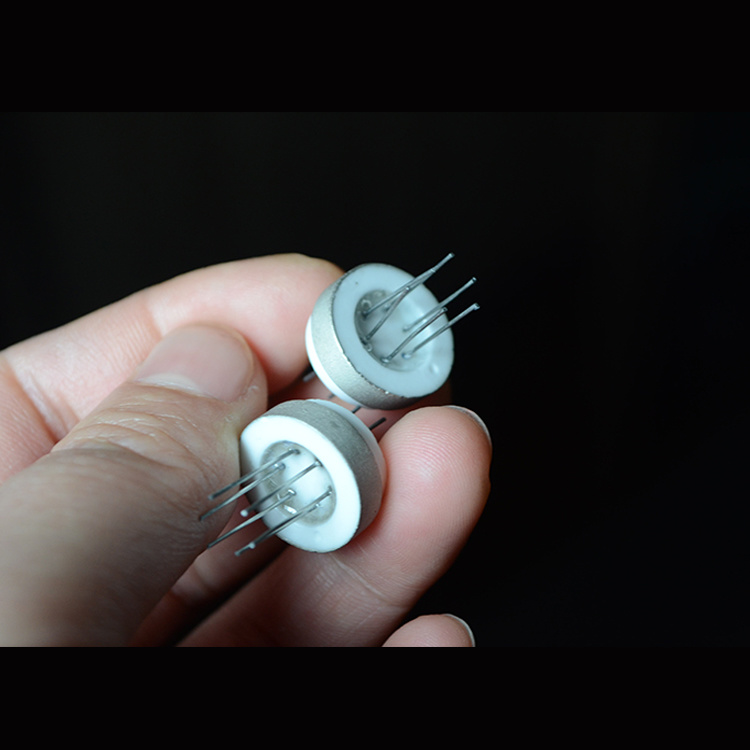

XTL sintyron Metallized Beryllium Oxide Beo Feedthrough Ceramic Vacuum Electrodes

Metallized Beryllium Oxide Vacuum Electrodes are a valuable component in high-power vacuum devices, but they require careful handling and monitoring to ensure safe and effective operation. By following proper safety precautions and monitoring the performance of the electrodes, they can be used effectively in a variety of applications in fields such as high-power microwave engineering and particle accelerator technology.

Contact usProducts Center

XTL sintyron Metallized Beryllium Oxide Beo Feedthrough Ceramic Vacuum Electrodes

Specifications

- Metallized Beryllium Oxide Vacuum Electrodes are designed for high performance in vacuum

- applications. These electrodes have a high purity beryllium oxide ceramic base material with a

- metallized coating to provide excellent electrical conductivity. The electrodes can withstand high

- temperatures up to 1000°C and have a low outgassing rate in vacuum environments. They have

- a high dielectric strength and low loss tangent for efficient energy transfer. The electrodes are

- available in various shapes and sizes to suit different applications and can be customized for

- specific requirements. Overall, Metallized Beryllium Oxide Vacuum Electrodes offer superior

- performance and reliability in vacuum systems.

Product Description

When using Metallized Beryllium Oxide (BeO) Vacuum Electrodes, there are several precautions that

need to be taken to ensure safe and effective operation. Beryllium oxide is a highly toxic material, so

it is important to handle it with care to prevent inhalation or skin contact. Additionally, beryllium oxide

is a known carcinogen, so proper ventilation and personal protective equipment should be used when

working with these electrodes.

In terms of application, Metallized Beryllium Oxide Vacuum Electrodes are commonly used in high-power

vacuum tubes, such as klystrons and magnetrons. These electrodes have excellent thermal conductivity

and electrical insulation properties, making them ideal for use in vacuum devices that require high power

handling capabilities.

One important consideration when using Metallized Beryllium Oxide Vacuum Electrodes is their high

thermal conductivity. This property allows the electrodes to efficiently dissipate heat generated during

operation, but it also means that they can reach very high temperatures. Therefore, it is important to

monitor the temperature of the electrodes to prevent overheating, which can lead to damage or failure

of the device.

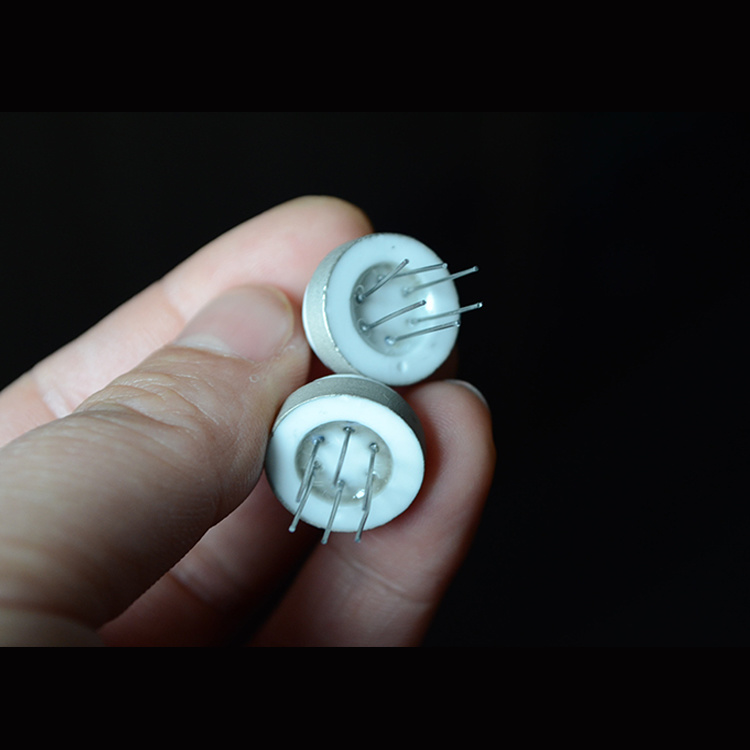

Another factor to consider when using Metallized Beryllium Oxide Vacuum Electrodes is their electrical

insulation properties. These electrodes are designed to provide a high degree of electrical insulation between

different components in a vacuum tube, so it is important to ensure that there are no defects or cracks in the

metallized coating that could compromise this insulation. Regular testing and inspection of the electrodes can

help identify any potential issues before they cause problems.

|

BeO Ceramic Properties |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Available in a variety of Thicknesses

2.062" square

2.25" square

2.9" x 2.3"

3.7" square

4.5" square

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t

have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.