PRODUCT CENTER

XING TAL LONG

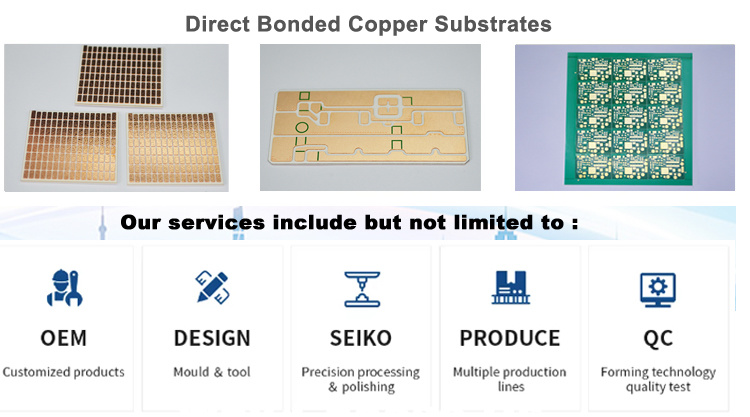

Recommended Products

XTL Sintyron Copper Clad Ceramic Substrate For Sensor Regulator

Our Ceramic Copper Clad Circuit Board is a high-performance solution designed specifically for demanding automotive applications, such as regulators and sensors. Built with advanced ceramic substrates and precision copper cladding, this circuit board delivers exceptional thermal conductivity, electrical insulation, and mechanical strength, making it ideal for harsh operating environments.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

XTL Sintyron Copper Clad Ceramic Substrate For Sensor Regulator

Our Ceramic Copper Clad Circuit Board is engineered to deliver exceptional performance, durability,

and reliability, making it the ideal choice for automotive regulators, sensors, and other critical electronic

components.

Parameter index

ceramic

| Item | Unit | Si3N4 | AlN | ZTA | BeO |

| Density | g/m³ | 3.2 | 3.3 | 4 | 3 |

| Thermal Conductivity | W/m.K@25℃ | ≥80 | ≥170 | ≥27 | ≥250 |

| Coefficient of Thermal Expansion | X10 -6 /K (20℃-300℃) |

≤2.6 | ≤4.3 | ≤7.5 | ≤9 |

| Flexural Strength | MPa | ≥700 | ≥450 | ≥500 | ≥190 |

| Dielectric Strength | KV/mm | ≥15 | ≥15 | ≥15 | ≥15 |

| Dielectric Loss | 1MHz | 0.0003 | 0.0003 | 0.0003 | 0.0003 |

| Dielectric Constant | 1MHz | 9 | 9 | 10.5 | 6.9 |

| Volume Resistivity | Ω·cm@ 20 °C | 10(14) | 10(14) | 10(14) | 10(14) |

| Young's Modulus | Gpa | 320 | 320 | 310 | / |

Copper Sheet

| Item | Unit | Performance |

| Thickness | mm | 0.127/0.2/0.25/0.3/0.4/0.5/0.8 |

| Oxygen Content | % | ≤0.001 |

| Surface Hardness | HV3 | 90-120(Post-Copper Cladding:45-55) |

| Conductivity | MS/m | 58.6 |

Standard Material Thickness Combinations

|

|

0.127mm | 0.2mm | 0.25mm | 0.3mm | 0.4mm | 0.5mm | 0.8mm |

| 0.25mm | AlN/Si3N4 | AlN/Si3N4 | AlN/Si3N4 | AlN/Si3N4 | AlN/Si3N4 | AlN/Si3N4 | AlN/Si3N4 |

| 0.32mm | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA | AlN/Si3N4/ZTA |

| 0.38mm | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO |

| 0.635mm | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO |

| 1.0mm | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO |

| 2.0mm | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO | AlN/Si3N4/BeO |

Product Features:

-

High Thermal Conductivity: The ceramic substrate, made from materials like aluminum oxide (Al2O3) or aluminum nitride (AlN),

-

ensures excellent heat dissipation, preventing overheating and ensuring stable performance in high-temperature automotive environments.

-

Superior Electrical Insulation: The ceramic base provides outstanding electrical insulation, reducing the risk of short circuits and enhancing the reliability of automotive electronic systems.

-

Durable Copper Cladding: The precision copper cladding offers high electrical conductivity, enabling efficient power distribution and signal transmission for automotive regulators and sensors.

-

Mechanical Strength: The ceramic substrate is highly resistant to mechanical stress, vibration, and impact, making it suitable for the demanding conditions of automotive applications.

-

Thermal Shock Resistance: The circuit board can withstand rapid temperature changes without cracking or degrading, ensuring long-term reliability in thermal cycling environments.

-

Corrosion and Wear Resistance: The ceramic material is resistant to corrosion and wear, extending the lifespan of the circuit board even in harsh operating conditions.

-

Customizable Designs: Available in various sizes, thicknesses, and configurations to meet specific automotive requirements, ensuring compatibility with different regulator and sensor systems.

-

High-Temperature Stability: Capable of operating reliably at elevated temperatures, making it ideal for use in automotive engines and other high-heat areas.

-

Compact and Lightweight: The compact design and lightweight nature of the ceramic substrate make it easy to integrate into automotive electronic systems without adding significant bulk.

-

Environmentally Friendly: The use of ceramic materials aligns with eco-friendly manufacturing practices, reducing the environmental impact of automotive electronics.

Alumina ceramic Substrate Application:

This product is widely used in automotive regulators, sensors, and other electronic systems where reliability

and performance are paramount. Its ability to withstand extreme conditions makes it a trusted choice for automotive

manufacturers seeking to enhance the efficiency and durability of their vehicles.

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.