PRODUCT CENTER

XING TAL LONG

Recommended Products

Sintyron High Temperature Resistance Insulated Precision 99% High Alumina Ceramic Accessories Ceramic Parts

A custom technical alumina ceramic end effector is an excellent solution for applications requiring high precision, durability, and resistance to harsh environments. By leveraging the unique properties of alumina ceramics, these end effectors can significantly improve the performance and longevity of robotic systems in industries such as semiconductor manufacturing, automation, and high-temperature processing.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

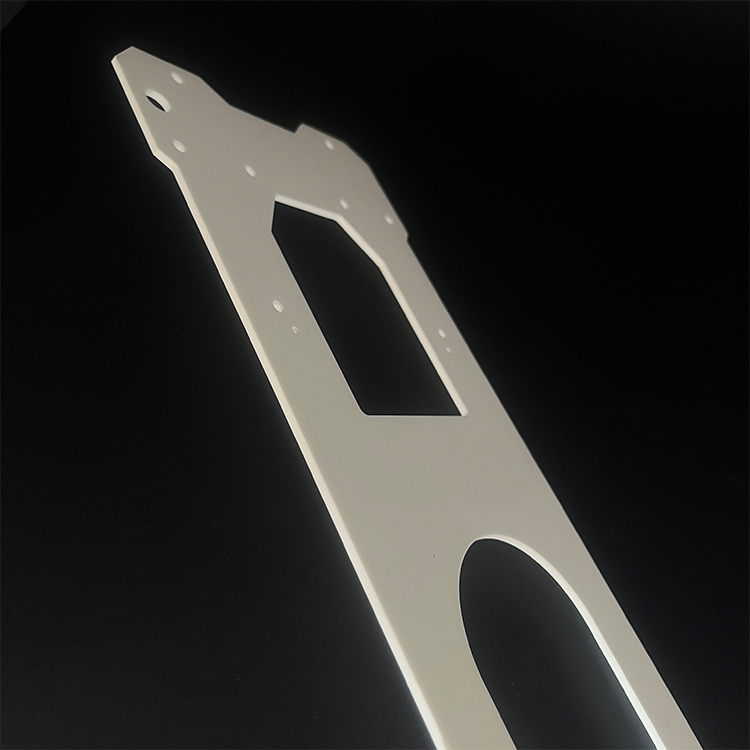

Custom Technical Alumina Ceramic End Effector

A custom technical alumina ceramic end effector is a specialized component designed

for specific industrial or robotic applications. End effectors are the devices at the end of a

robotic arm or tool that interact directly with the environment or workpiece. When made

from alumina ceramic (aluminum oxide, Al₂O₃), these end effectors leverage the material's

unique properties to perform in demanding conditions.

Product description

Material Introduction:

√ High Voltage Insulator | √ High Purity, Max. 99.8% | √ Various Available Grades |

√ Hard and Wear Resistant | √ High Corrosion Resistance | √ High Mechanical Strength |

√ Good Thermal Conductivity | √ High Operating Temperature | √ Most Favorable Fine Ceramic |

Key Properties of Alumina Ceramic for End Effectors

High Hardness: Alumina ceramics are extremely hard, making them resistant to wear and abrasion.

Thermal Stability: They can withstand high temperatures without degrading, making them suitable for high-temperature processes.

Chemical Resistance: Alumina is inert and resistant to most chemicals, acids, and alkalis.

Electrical Insulation: Alumina ceramics are excellent electrical insulators, making them ideal for applications involving electrical components.

Low Density: Alumina is lightweight compared to metals, reducing the overall weight of the robotic system.

Smooth Surface Finish: The material can be polished to a very smooth finish, reducing friction and improving performance.

| Composition | AL95 | AL99 |

| Color | White | Ivory |

| Density (g/cm3 ) | 3.72 | 3.85 |

| Thermal conductivity (W/m. K) | 22.3 | 32 Kpsi |

| Thermal Expansion (x10-6 /℃) | 8 | 8.2 |

| Dielectric Constant (at 1MHZ) | 9.5 | 9.8 |

| Loss Tangent (x10-4 at 1MHZ) | 3 | 2 |

| Volume Resistivity (ohm-m) | >1014 | >1014 |

| Flexural Strength (N/mm2 ) | 350 | 500 |

Applications of Custom Alumina Ceramic End Effectors

Semiconductor Manufacturing:

Handling silicon wafers, chips, and other delicate components.

Resisting electrostatic discharge (ESD) and contamination.

High-Temperature Environments:

Used in furnaces, kilns, or welding applications where heat resistance is critical.

Abrasive Material Handling:

Gripping or manipulating abrasive materials like glass, ceramics, or metals.

Medical and Pharmaceutical Industries:

Handling sensitive materials in sterile environments due to alumina's biocompatibility and chemical resistance.

Automation and Robotics:

Precision gripping, lifting, or positioning of components in manufacturing processes.

Electronics Assembly:

Handling small, delicate electronic components without causing damage.

FAQ:

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea,

we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.