PRODUCT CENTER

XING TAL LONG

Recommended Products

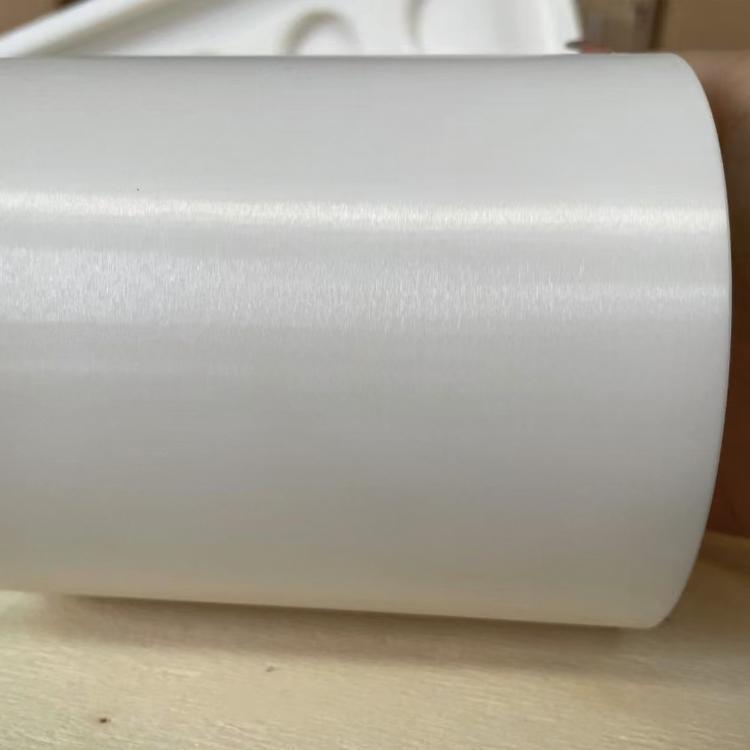

XTL Sintyron yttria stabilized zirconia ceramic crucible

A zirconia grinding jar is a highly durable, wear-resistant, and chemically inert container designed for efficient and contamination-free grinding of tough materials in laboratory and industrial applications.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

XTL Sintyron zirconia ceramic ball mill grinding jar with lids

A zirconia grinding jar is a specialized container used in ball milling or grinding processes,typically

for grinding, mixing, or homogenizing materials. It is made from zirconia (zirconium dioxide, ZrO₂),

a advanced ceramic material known for its exceptional hardness, wear resistance,and chemical inertness.

Zirconia grinding jars are commonly used in laboratories and industrial settings for sample preparation in

fields like materials science, pharmaceuticals, ceramics, and chemistry.

Key Features of Zirconia Grinding Jars:

Material Properties:

High Hardness: Zirconia is one of the hardest ceramic materials, making it ideal for grinding tough materials.

Wear Resistance: Resistant to abrasion, ensuring a long lifespan even with continuous use.

Chemical Inertness: Resistant to acids, alkalis, and other corrosive substances, making it suitable for grinding

a wide range of materials.

High Density: Provides excellent grinding efficiency due to its high mass.

Low Contamination: Zirconia is non-porous and does not react with most materials, ensuring minimal

contamination of samples.

Design:

Available in various sizes and capacities (e.g., 50 mL to several liters).

Typically cylindrical in shape with a tight-sealing lid to prevent sample loss or contamination.

Compatible with most ball mills and grinding equipment.

Grinding Media Compatibility:

Often used with zirconia grinding balls for optimal performance and minimal contamination.

Can also be used with other grinding media like stainless steel, alumina, or tungsten carbide, depending

on the application.

Applications of Zirconia Grinding Jars:

Sample Preparation: Grinding and homogenizing powders for analysis in laboratories.

Nanomaterial Production: Used in the synthesis of nanoparticles and advanced materials.

Pharmaceuticals: Grinding active pharmaceutical ingredients (APIs) and excipients.

Ceramics and Minerals: Preparing ceramic powders or grinding minerals for analysis.

Food Industry: Grinding food samples for testing or research.

Battery Materials: Used in the preparation of electrode materials for lithium-ion batteries.

Advantages of Zirconia Grinding Jars:

Durability: Long-lasting even under harsh grinding conditions.

High Grinding Efficiency: Due to the high density and hardness of zirconia.

Minimal Contamination: Ideal for applications requiring high purity.

Versatility: Suitable for wet or dry grinding processes.

Material | Hardness | Wear Resistance | Chemical Resistance | Cost | Best For |

Zirconia | Very High | Excellent | Excellent | High | High-purity, tough materials |

Alumina | High | Good | Good | Moderate | General-purpose grinding |

Stainless Steel | Medium | Moderate | Moderate |

| Non-contaminating applications |

Tungsten Carbide | Very High | Excellent | Good |

| Extremely tough materials |

| Y-FSZ Ceramic Properties | ||

| Chemical content | ZrO2 | 86 wt% |

| Y2O3 | 14 wt% | |

| Physical Properties | Melting point | ≥2500℃ |

| Max. operating temperature | 2200℃ | |

| Color | White | |

| Density | 5.8g/cm3 | |

| Mechanical properties | Flexural strength | 200MPa |

| Young’s module | 200GPa | |

| Hardness(HRA) | 86 | |

| Thermal properties | Thermal expansion coefficient(20℃) | 8-10X10-6 |

| Thermal conductivity | 1-2W/mk | |

| Electrical properties | Dielectric constant(1MHz25℃) | 12 |

| Electrical resistivity(25℃) | 109 | |

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t

have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.