PRODUCT CENTER

XING TAL LONG

Recommended Products

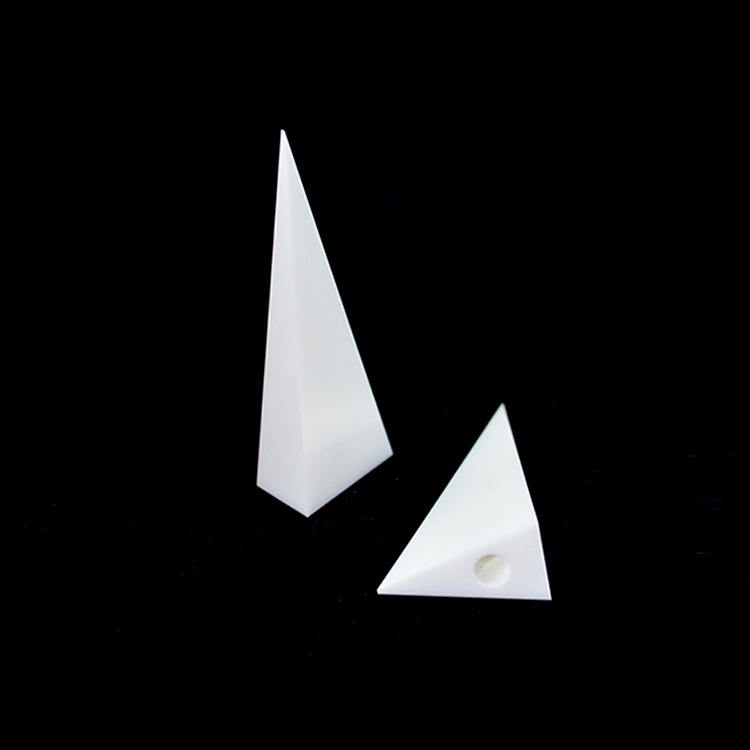

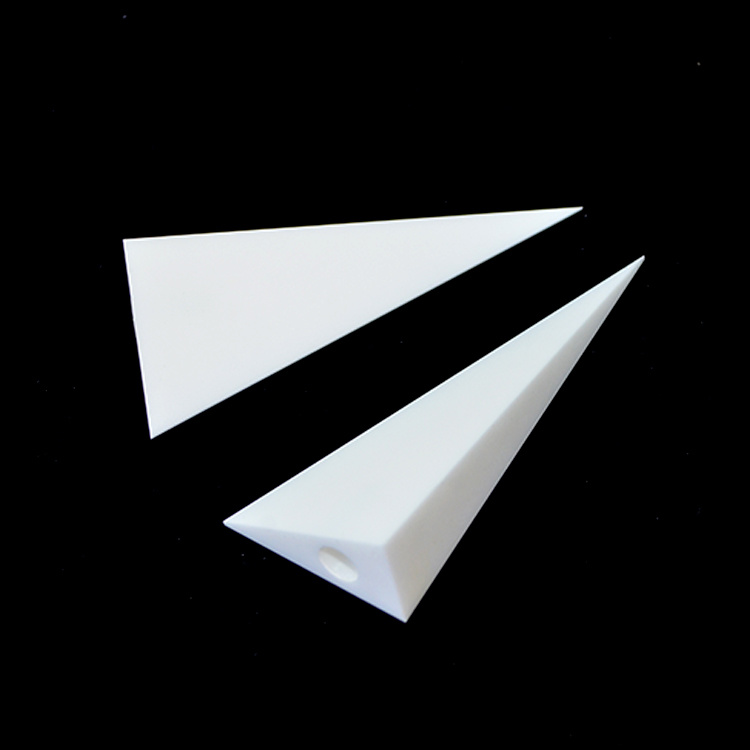

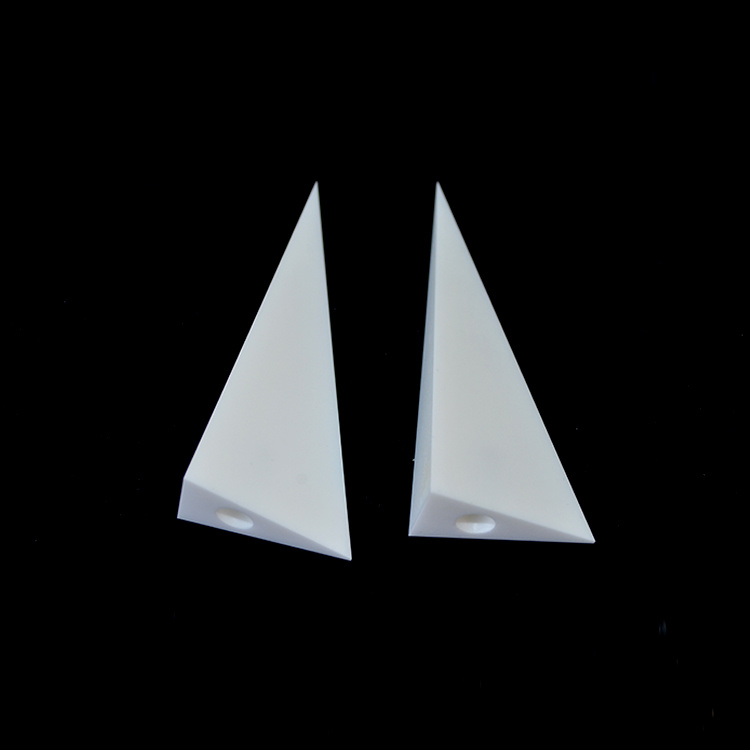

XTL Sintyron Customized Precision Industrial Zro2 Zirconia Ceramic Cutting Blades

zirconia ceramic inserts offer a combination of hardness, thermal stability, and chemical inertness, making them ideal for high-performance machining applications on large mechanical machine tools. Their features and benefits lead to increased productivity, cost savings, and improved machining accuracy, making them a valuable choice for modern manufacturing environments.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

Customized Precision Industrial Zro2 Zirconia Ceramic Cutting Blades

Zirconia Ceramic Inserts for Large Mechanical Machine Tools: Advantages, Features, and Benefits

Advantages:

Exceptional Hardness and Wear Resistance: Zirconia ceramic inserts exhibit superior hardness, making them

highly resistant to wear and abrasion. This ensures prolonged tool life even under demanding machining conditions.

High Thermal Stability: These inserts maintain their mechanical properties at elevated temperatures, reducing the

risk of thermal deformation and ensuring consistent performance during high-speed machining.

Chemical Inertness: Zirconia is chemically inert, which means it resists reactions with most materials, reducing

the likelihood of chemical wear and extending the tool's lifespan.

Low Thermal Conductivity: The low thermal conductivity of zirconia helps in maintaining the heat in the cutting

zone, which can improve the machining process by softening the material being cut, thus reducing cutting forces.

Features:

High Fracture Toughness: Compared to other ceramics, zirconia has higher fracture toughness, which reduces

the likelihood of chipping or breaking during interrupted cuts or when machining hard materials.

Precision Engineering: Zirconia inserts are manufactured to very tight tolerances, ensuring high precision in

machining applications, which is crucial for large mechanical machine tools.

Versatility: These inserts are suitable for a wide range of materials, including hardened steels, cast irons, superalloys,

and non-ferrous metals, making them versatile for various industrial applications.

Surface Finish: The use of zirconia inserts can result in superior surface finishes, reducing the need for additional

finishing processes and saving time and costs.

| Y-FSZ Ceramic Properties | ||

| Chemical content | ZrO2 | 86 wt% |

| Y2O3 | 14 wt% | |

| Physical Properties | Melting point | ≥2500℃ |

| Max. operating temperature | 2200℃ | |

| Color | White | |

| Density | 5.8g/cm3 | |

| Mechanical properties | Flexural strength | 200MPa |

| Young’s module | 200GPa | |

| Hardness(HRA) | 86 | |

| Thermal properties | Thermal expansion coefficient(20℃) | 8-10X10-6 |

| Thermal conductivity | 1-2W/mk | |

| Electrical properties | Dielectric constant(1MHz25℃) | 12 |

| Electrical resistivity(25℃) | 109 | |

Benefits:

Increased Productivity: Due to their wear resistance and ability to withstand high temperatures, zirconia inserts allow

for higher cutting speeds and feed rates, significantly increasing productivity.

Cost Efficiency: The extended tool life and reduced need for frequent replacements translate into lower tooling costs

over time.

Improved Machining Accuracy: The precision and stability of zirconia inserts contribute to improved dimensional

accuracy and repeatability in machined parts.

Reduced Downtime: With their durability and reliability, zirconia inserts minimize machine downtime for tool changes,

enhancing overall operational efficiency.

Environmental Benefits: The longevity and efficiency of zirconia inserts contribute to reduced waste and energy

consumption, aligning with sustainable manufacturing practices.

FAQ

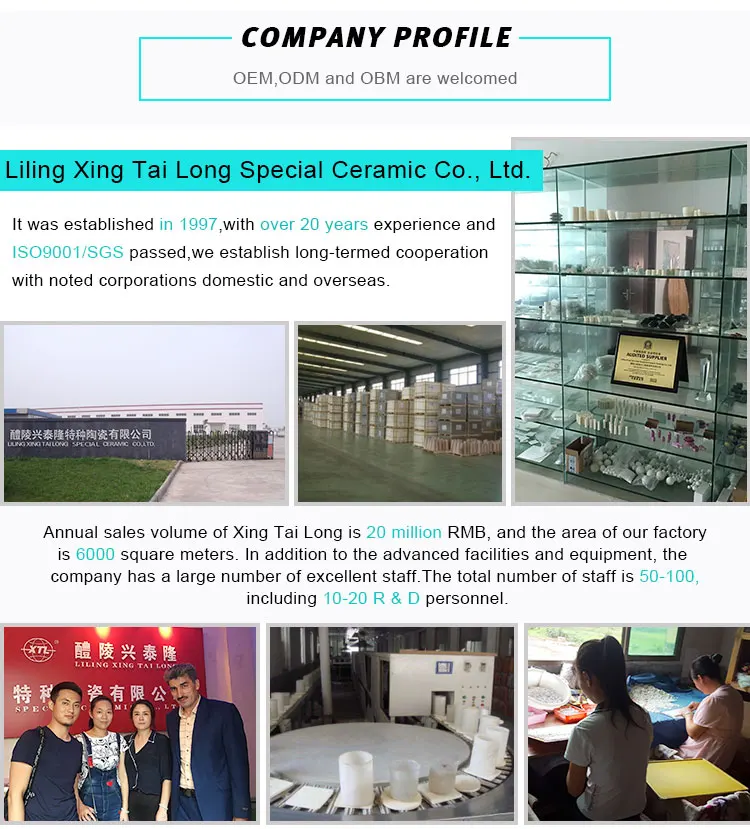

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.