PRODUCT CENTER

XING TAL LONG

Recommended Products

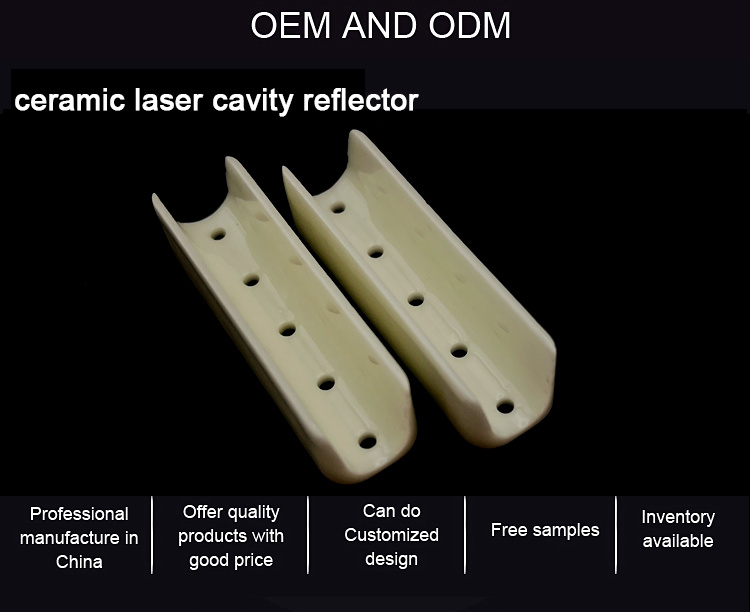

XTL sintyron custom glazing alumina ceramic tube laser pumped cavity ceramic reflector

The ceramic laser cavity reflector is a high-precision, thermally stable component designed for optimal reflectivity and durability in laser systems.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

Custom glazing alumina ceramic tube laser pumped cavity ceramic reflector

Product description:

The custom glazing alumina ceramic tube laser pumped cavity ceramic reflector is a precision-engineered,

high-performance component designed for superior thermal management, optical reflectivity, and durability

in laser applications.

Material Introduction:

|

√ High Voltage Insulator |

√ High Purity, Max. 99.8% |

√ Various Available Grades |

|

√ Hard and Wear Resistant |

√ High Corrosion Resistance |

√ High Mechanical Strength |

|

√ Good Thermal Conductivity |

√ High Operating Temperature |

√ Most Favorable Fine Ceramic |

Specification :

| Composition | AL95 | AL99 |

|

Color |

White | Ivory |

|

Density (g/cm3 ) |

3.72 |

3.85 |

|

Thermal conductivity (W/m. K) |

22.3 |

32 Kpsi |

|

Thermal Expansion (x10-6 /℃) |

8 | 8.2 |

|

Dielectric Constant (at 1MHZ) |

9.5 | 9.8 |

|

Loss Tangent (x10-4 at 1MHZ) |

3 | 2 |

|

Volume Resistivity (ohm-m) |

>1014 |

>1014 |

|

Flexural Strength (N/mm2 ) |

350 |

500 |

A ceramic laser cavity reflector is a component used in laser systems to reflect and amplify the light

produced by the laser. The reflector is typically made of a high-quality ceramic material that has a

high reflectivity in order to efficiently bounce the laser light back and forth within the cavity.

To use a ceramic laser cavity reflector, it must be carefully installed within the laser cavity in a precise

position to maximize the reflection of the laser light. This is typically done by mounting the reflector

onto a holder or mount that can be adjusted to position the reflector at the optimal angle for reflection.

Once the reflector is properly installed, the laser system can be powered on and the laser light will be

directed into the cavity. The reflector will then bounce the light back and forth between the cavity mirrors,

amplifying and concentrating the light into a coherent beam.

It is important to regularly inspect and clean the ceramic laser cavity reflector to ensure that it remains

in optimal condition for efficient reflection of the laser light. Any dirt or debris on the reflector surface

can disrupt the reflection and reduce the performance of the laser system.

Application:

Pumping chambers for flash lamp, Nd: YAG lasers, alexendrite laser, diode pumped lasers. Cosmetic surgery intense pulse light (IPL).

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t

have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.