PRODUCT CENTER

XING TAL LONG

Recommended Products

SINTYRON Si3n4 Ceramic Super Grinding Silicon Nitride Balls

Grinding silicon nitride balls requires ultra-precision diamond grinding, controlled lapping, and polishing to meet stringent tolerances. Advanced CNC grinding machines and CMP techniques are essential for achieving the required nanoscale smoothness and sphericity.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

Si3n4 Ceramic Super Grinding Silicon Nitride Balls Description

1. General Requirements for Si₃N₄ Balls (Final Product) | ||

Parameter | Standard Grades (ISO 3290) | Ultra-Precision Grades |

Diameter Tolerance | ±0.5 µm (Grade 5) | ±0.1 µm (Grade 3) |

Sphericity (Roundness) | < 0.1 µm | < 0.05 µm |

Surface Roughness (Ra) | < 0.02 µm | < 0.01 µm (mirror finish) |

Waviness | < 0.05 µm | < 0.02 µm |

Material Hardness | ~1500 HV (Vickers) | Same |

2:Critical Quality Control Metrics | ||

Inspection Method | Measured Parameter | Acceptable Range |

Roundness Tester (Talyrond) | Sphericity (∆r) | < 0.1 µm (Grade 5) |

White-Light Interferometer | Surface Roughness (Ra) | < 0.02 µm |

SEM/EDS Analysis | Subsurface cracks/defects | None allowed |

Hardness Tester (Vickers) | Material Hardness | 1400–1600 HV |

1. Key Challenges in Grinding Si₃N₄ Balls

High Hardness: Requires diamond or CBN (cubic boron nitride) abrasives.

Brittleness: Risk of edge chipping or subsurface damage if grinding parameters are incorrect.

Tight Tolerances: Precision balls require Grade 3 to Grade 10 (ISO 3290) with:

Sphericity: < 0.1 µm for high-end bearings.

Surface Roughness (Ra): < 0.01 µm.

Diameter Tolerance: ±0.1 µm (for ultra-precision grades).

2. Grinding Process for Si₃N₄ Balls

A. Rough Grinding (Precision Shaping)

Abrasive: Diamond grinding wheels (resin or metal-bonded).

Method:

Lapping machines or ball grinding machines (e.g., Koyo, Peter Wolters).

Balls are rotated between two counter-rotating cast iron plates with abrasive slurry.

Goal: Achieve near-net shape (~5–10 µm oversize).

B. Fine Grinding (Semi-Finishing)

Abrasive: Finer diamond grit (D15–D7, ~15–7 µm).

Method:

Planetary ball grinders with controlled pressure.

Uses a ceramic-bonded diamond wheel for better surface finish.

Goal: Reduce sphericity error to < 1 µm.

C. Precision Lapping/Polishing (Final Finish)

Abrasive: Diamond or boron carbide (B₄C) slurry (0.5–3 µm grit).

Method:

Magnetic float polishing (for ultra-smooth finishes).

Chemical-mechanical polishing (CMP) for mirror finishes.

Goal: Achieve Ra < 0.01 µm and sphericity < 0.1 µm.

Applications of Ground Si₃N₄ Balls

Hybrid Bearings (e.g., aerospace, machine tools)

High-Speed Spindles (CNC machines)

Valve Components (chemical pumps)

Medical Implants (due to biocompatibility)

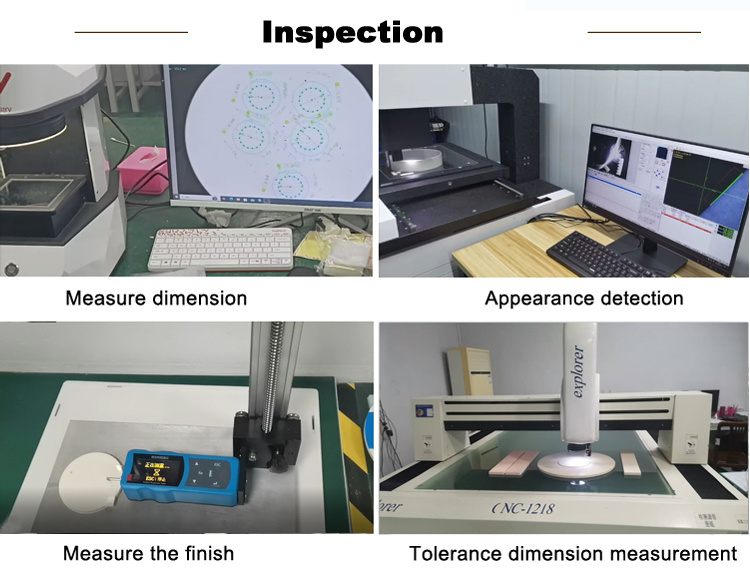

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea,

we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.