PRODUCT CENTER

XING TAL LONG

Recommended Products

XTL Sintyron refractory furnace lining ceramic plates

92%/95% alumina wear protection lining plates are high-performance ceramic liners offering excellent abrasion and corrosion resistance, with 95% alumina providing superior durability for harsher conditions

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

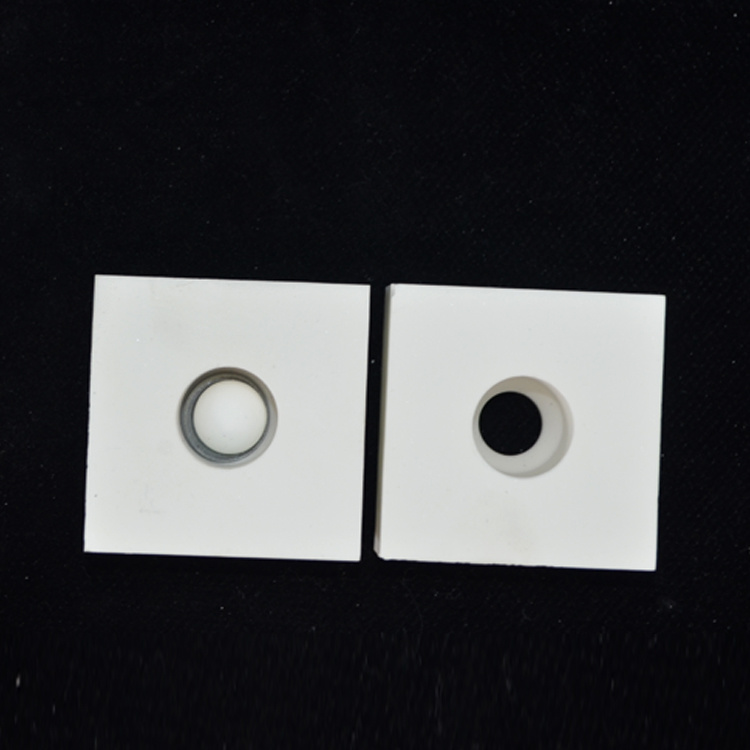

XTL Sintyron 92%95% alumina wear protection lining plate

Product description:

Alumina (Al₂O₃) ceramic lining plates are widely used for abrasion and corrosion resistance in

industries like mining, cement, and power plants. The alumina content (92% vs. 95%) significantly

affects performance, cost, and suitability for different applications.

Specification :

Key Features:

High Wear Resistance: Excellent for extending the lifespan of equipment in abrasive environments.

Impact Resistance: Withstands heavy impacts and mechanical stress.

Corrosion Resistance: Resistant to chemicals and corrosive substances.

High Temperature Tolerance: Can operate in high-temperature environments.

Lightweight: Compared to metal liners, alumina plates are lighter, reducing equipment load.

Design and Installation:

Available in various shapes (rectangular, square, trapezoidal) and thicknesses (typically 5-20 mm).

Can be attached to equipment surfaces using adhesives, bolts, or welding (with embedded metal backing).

Customizable to fit specific equipment dimensions.

Comparison: 92% vs. 95% Alumina Lining Plates

| Property | 92% Al₂O₃ | 95% Al₂O₃ |

| Alumina Content | 92% + additives (SiO₂, CaO, etc.) | 95% + minor additives |

| Density | ~3.6 g/cm³ | ~3.7 g/cm³ |

| Hardness (Mohs) | ~8.5 | ~9.0 |

| Wear Resistance | Good (for moderate abrasion) | Excellent (for severe abrasion) |

| Impact Strength | Slightly better (due to additives) | Lower (more brittle) |

| Corrosion Resistance | Good (resists most acids/alkalis) | Better (higher purity) |

| Temperature Limit | Up to 1400°C | Up to 1600°C |

| Cost | Lower (~20-30% cheaper) | Higher (premium performance) |

Applications:

Mining and Mineral Processing: Chutes, hoppers, and conveyor systems.

Cement Industry: Raw mill liners, cyclones, and pipelines.

Power Plants: Coal handling and ash disposal systems.

Steel Industry: Blast furnaces and sinter plants.

Chemical Industry: Equipment exposed to corrosive materials.

Advantages:

Significantly reduces downtime and maintenance costs.

Improves operational efficiency by minimizing material buildup.

Longer service life compared to traditional metal liners.

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.