PRODUCT CENTER

XING TAL LONG

SINTYRON high thermal conductivity corrosion-resistant aluminum nitride wear ceramic ring rod

High-performance Aluminum Nitride (AlN) ceramic components for semiconductor equipment, offering superior thermal conductivity, plasma resistance, and precision machining for critical wafer processing applications.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

SINTYRON high thermal conductivity corrosion-resistant aluminum nitride wear

ceramic ring rod

Product descritption:

Density: (3.1~3.3) g/cm3

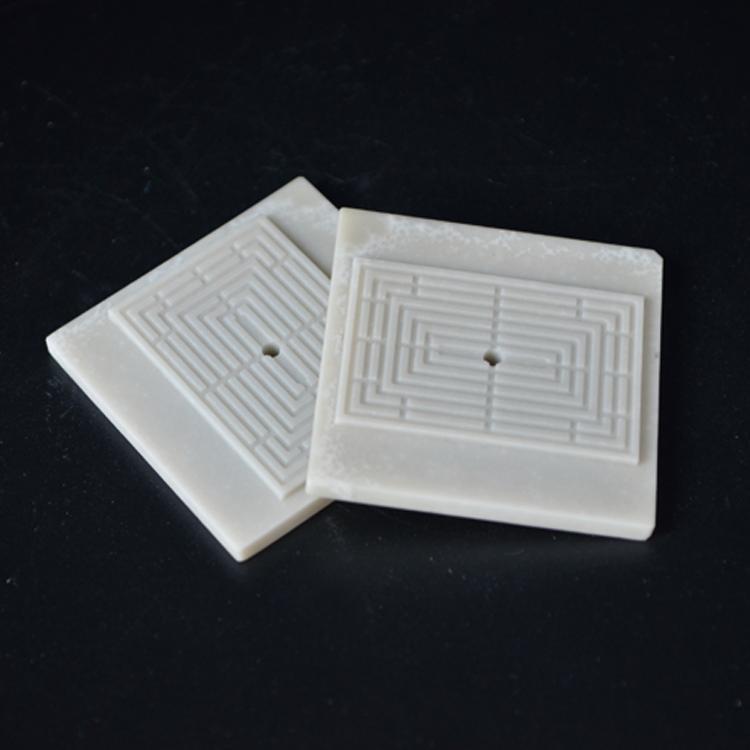

Processing range: maximum shape 600*600*400mm

Accuracy range: flatness: 0.002mm, parallelism, verticality: 0.005mm, Ra:0.2um

Our precision-engineered Aluminum Nitride (AlN) structural components are critical for

advanced semiconductor manufacturing, offering:

1:220+ W/mK thermal conductivity – 8x better than alumina

2:>1014 Ω·cm volume resistivity – ideal for RF applications

3:CTE matched to silicon wafers (4.5×10⁻⁶/°C)

4:Corrosion-resistant in Cl₂/CF₄ plasma environments

Performance For Industrial Ceramic

| Item | Unit | Our standard | |

| Appearance | Color | - | Gray / Beige |

| Microstructure | - | Dense and fine grain | |

| SurfaceRoughness() | μm | 0.46 | |

| Warpage | ‰ | <2.5 | |

| Physical | Water Absorption | % | 0.061 |

| Vickers Hardness | GPa | 12 | |

| Young Modulus | GPa | 330 | |

| VolumeDensity | g/Cm3 | ≥3.24 | |

| BendingStrength | [3-point Method]MPa | >350 | |

| Thermal | @20℃ThermalConductivity | [@20℃]W/m·k | ≥170 |

| CoefficientofLinear Expansion | RT-300℃]10-6mm/℃ | 4.6 | |

| Electrical | Volume Resistance | Ω·cm | 1.5×1013 |

| [@1MHz] Dielectric Constant | - | 10.6 | |

| [@1MHz] Dielectric Loss | - | 4.6×10-4 | |

| Dielectric Strength | (KV/mm) | ≥20 | |

Semiconductor Applications:

Etch Systems:

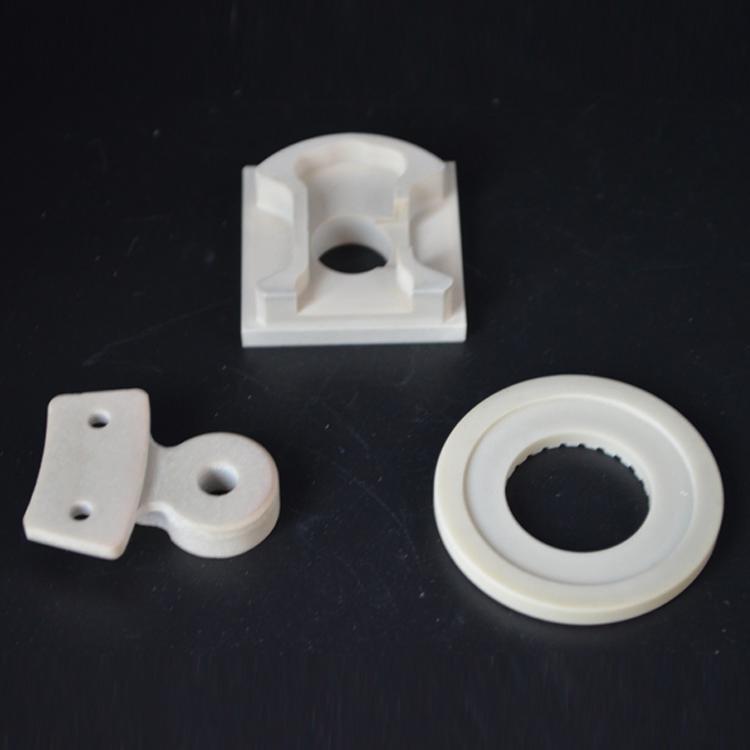

Plasma confinement rings

Gas distribution plates

Chamber liners

Deposition Tools:

CVD heater pedestals

PVD shield components

Lithography

EUV mirror substrates

Vacuum chuck components

Packaging & Testing

Thermal management substrates

Probe card insulators

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

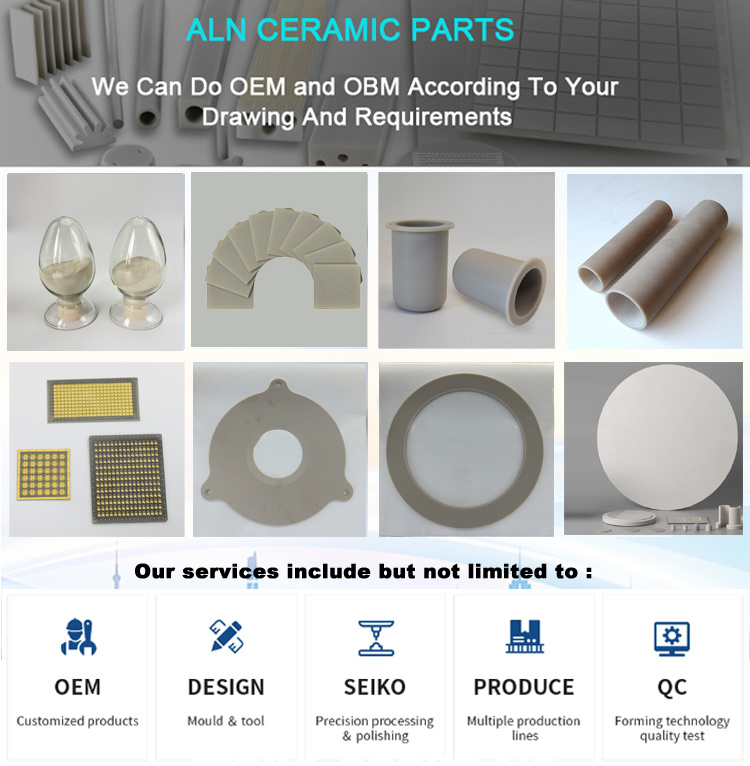

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.