PRODUCT CENTER

XING TAL LONG

Recommended Products

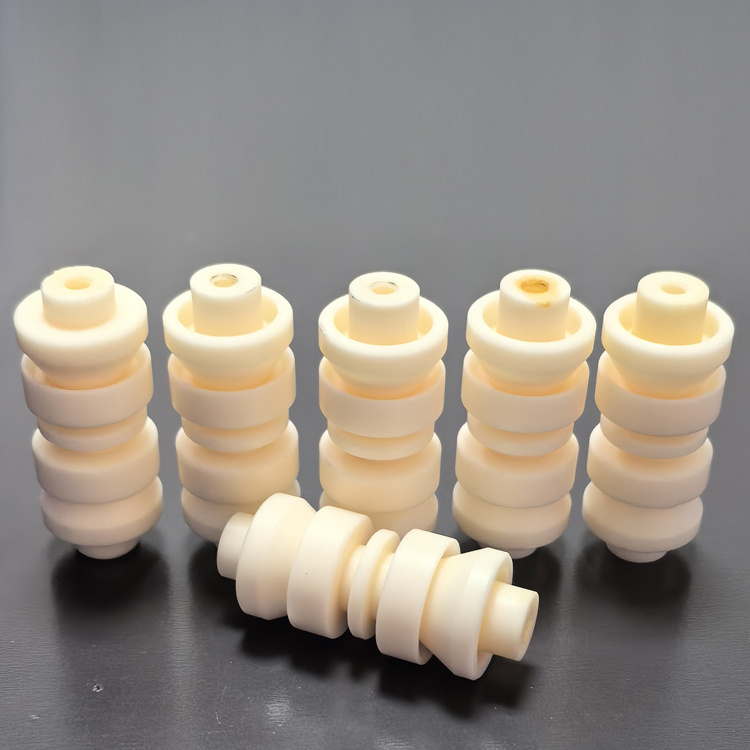

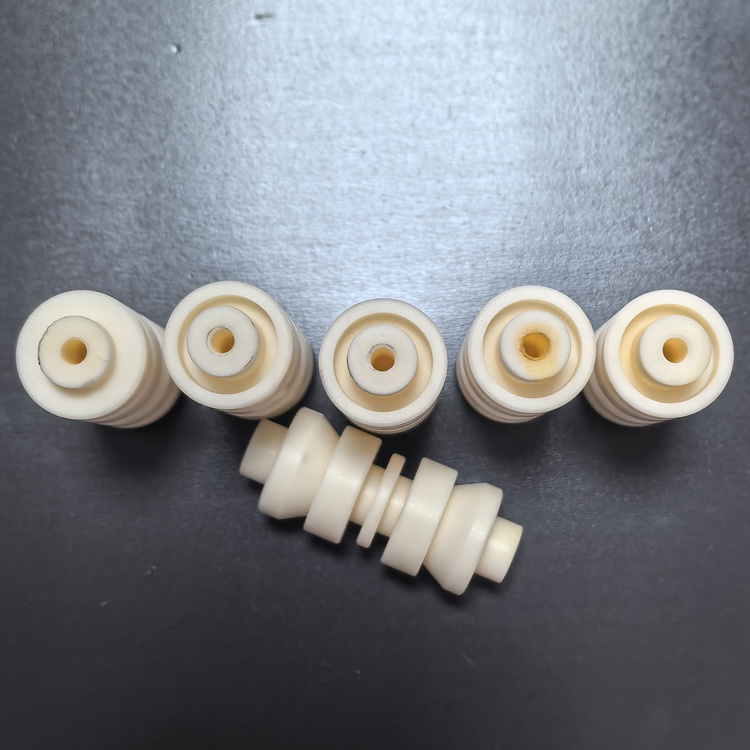

SINTYRON 95% 99% 99.5% al2o3 insulator alumina ceramic part

Precision-machined Al₂O₃ 95%/99%/99.5% components designed for ion implanters

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

95% 99% 99.5% al2o3 insulator alumina ceramic part

Product description:

Premium-grade alumina ceramic parts designed for extreme electrical insulation, high-temperature

resistance, and mechanical stability. Available in 95%, 99%, and 99.5% purity levels to meet diverse

industrial requirements.

1:Certified Quality 2:Custom Sizes 3:Fast Global Shipping

Technical Specifications

| Parameter | 95% Al₂O₃ | 99% Al₂O₃ | 99.5% Al₂O₃ |

| Density (g/cm³) | 3.6-3.7 | 3.8-3.9 | ≥3.9 |

| Dielectric Strength (kV/mm) | ≥10 | ≥15 | ≥18 |

| Thermal Conductivity (W/m·K) | 20-25 | 25-30 | 30-35 |

| Flexural Strength (MPa) | 300-350 | 350-400 | 400-450 |

Material Introduction:

√ High Voltage Insulator | √ High Purity, Max. 99.8% | √ Various Available Grades |

√ Hard and Wear Resistant | √ High Corrosion Resistance | √ High Mechanical Strength |

√ Good Thermal Conductivity | √ High Operating Temperature | √ Most Favorable Fine Ceramic |

Specification :

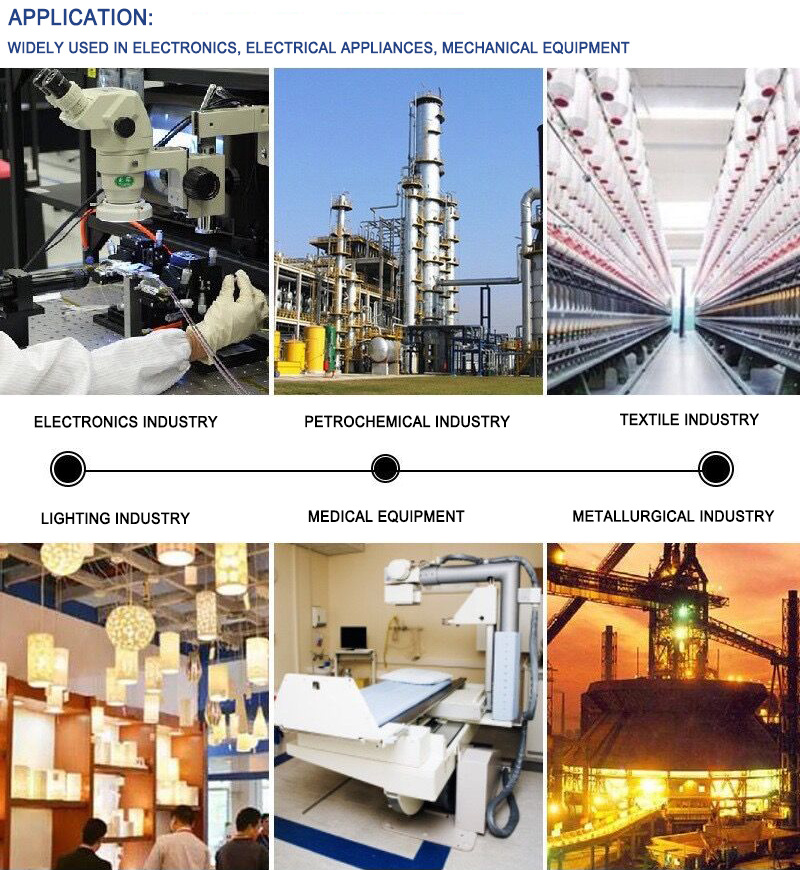

Alumina ceramic components and parts are widely used in various industries due to their excellent properties such as high hardness, wear resistance, corrosion resistance, and electrical insulation. These components are made from alumina oxide, a high-performance ceramic material that is known for its superior mechanical strength and thermal stability.

Alumina ceramic components and parts can be found in a wide range of applications, including but not limited to:

1. Electrical and electronic industries: Alumina ceramic components are commonly used in the manufacturing of insulators, substrates, and circuit boards for electronic devices. They provide excellent electrical insulation and thermal conductivity, making them ideal for high-temperature and high-voltage applications.

2. Aerospace and defense industries: Alumina ceramic components are used in aircraft engines, missile systems, and radar equipment due to their high temperature resistance and wear properties. They are also used in armor plating and protective systems for military vehicles.

3. Medical and dental industries: Alumina ceramic components are used in dental implants, prosthetic limbs, and surgical instruments due to their biocompatibility and resistance to corrosion. They are also used in medical imaging equipment such as X-ray tubes and MRI scanners.

4. Automotive industry: Alumina ceramic components are used in automotive engines, exhaust systems, and braking systems due to their high temperature resistance and wear properties. They are also used in sensors, fuel injectors, and spark plugs.

5. Semiconductor industry: Alumina ceramic components are used in semiconductor manufacturing equipment such as wafer chucks, vacuum chambers, and ion implanters. They provide excellent chemical resistance and thermal stability required for semiconductor fabrication processes.

Feature

1.good thermal conductivity

2.excellent electrical insulation

3.corrosion & erosion resistant

4.thermal shock resistant

5.high working temperature

6.low thermal expansion

7.very hard, wear resistant

8.high mechanical strength

9.flexible custom production

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.