PRODUCT CENTER

XING TAL LONG

SINTYRON Customized Yellow Magnesium Stabilized Zirconia Ceramic Plunger

A yellow magnesium-stabilized zirconia ceramic plunger is a specialized component made from zirconium dioxide (ZrO₂) that has been stabilized with magnesium oxide (MgO) and colored yellow, typically through the addition of rare earth pigments or other coloring agents.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

SINTYRON Customized Yellow Magnesium Stabilized Zirconia Ceramic Plunger

Magnesia Stabilized Zirconia (MSZ) Ceramic Plunger is a great refractory

and insulating material due to high oxygen ion conductivity, high strength and toughness, and good

thermal shock resistance. It has a clean melt at temperatures above 1900°C and above and is specially

manufactured for melting superalloys and precious metals. Its superior thermal shock resistance to

temperatures reaching up to 2200°C.

Technical Indicators | |||||

Indicators | ltem | Units | MSZ-H | MSZ-L | Custom |

Main Composition | ZrO2 | % | ≥95 | ≥95 | 60-95 |

AI203 | % | ≤0.2 | ≤0.2 | 0.2-20 | |

SiO2 | % | ≤0.4 | ≤0.4 | 0.2-1 | |

MgO | % | ≤2.9 | ≤2.9 | MgO/Y203 | |

Fe203 | % | ≤0.1 | ≤0.1 | 0.1-0.3 | |

TiO2 | % | ≤0.1 | ≤0.1 | 0.1-1.0 | |

Physical | Color | - | Yellow | Yellow | Yellow/White |

Density | g/cm3 | ≤5.2 | 5.4-5.60 | 4.6-5.6 | |

Porosity | % | ≤18.5 | ≤8 | 1-18.5 | |

| The stabilizers, grains combination and porosity can be designed according to customer's using environment. | |||||

* High wear-resistant and erosion-resistant

* Metal corrosion resistance in high temperature

* Excellent non-wetting characteristics

* High strength

* Long service life

* The stabilizers and grains combination can be designed according to customer's using environment.

Application Temperature

0°C-2200

Applicable Environment

Air, Vacuum, or Atmosphere Protection Environment

Application Field

Sizing nozzle, Ladle skateboard panel, Converter slag blocking slide plate and ring, etc.

Specialty glass manufacturing

Large size high content of zirconia and alumina ceramics, etc.

Metal powder industry

Setter plate, Gas atomizing nozzle, etc.

Precious metal smelting industry

Ceramic Crucibles, etc.

Artificial/Laser Crystal Ceramic Temperature Field

Rare earth composite oxide solid solution ceramic temperature field, etc

FAQ

Why us?

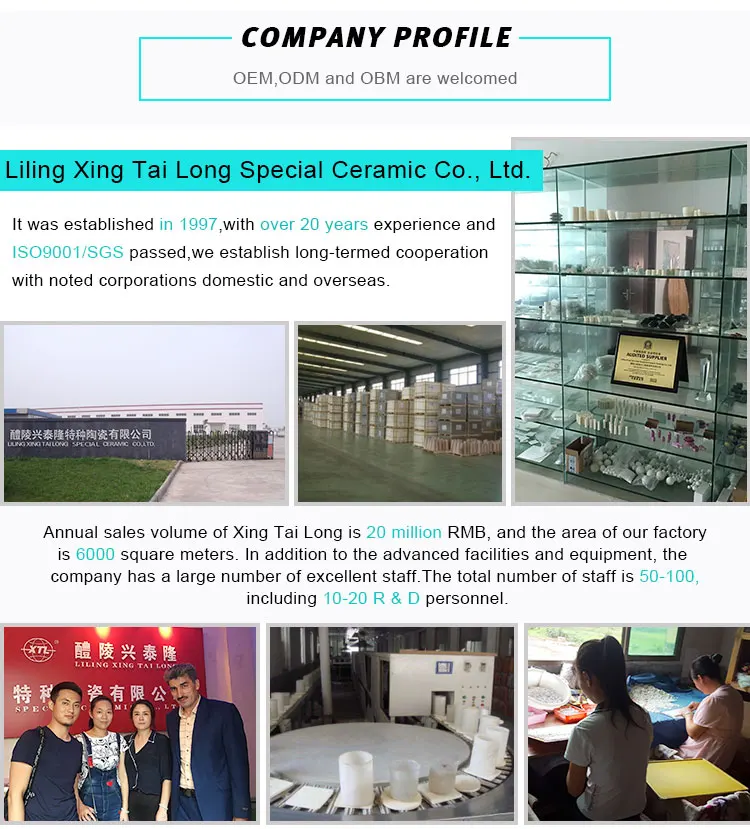

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.