PRODUCT CENTER

XING TAL LONG

Recommended Products

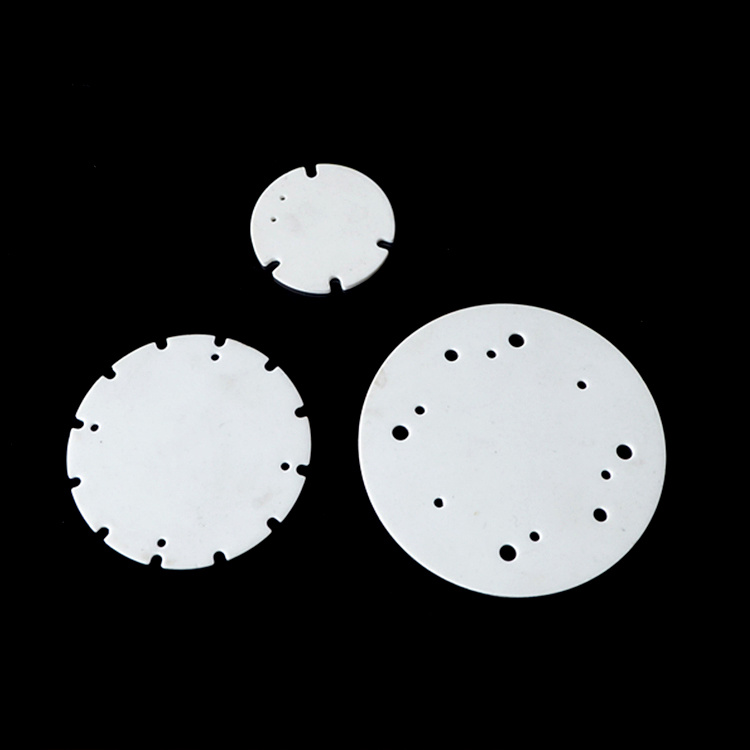

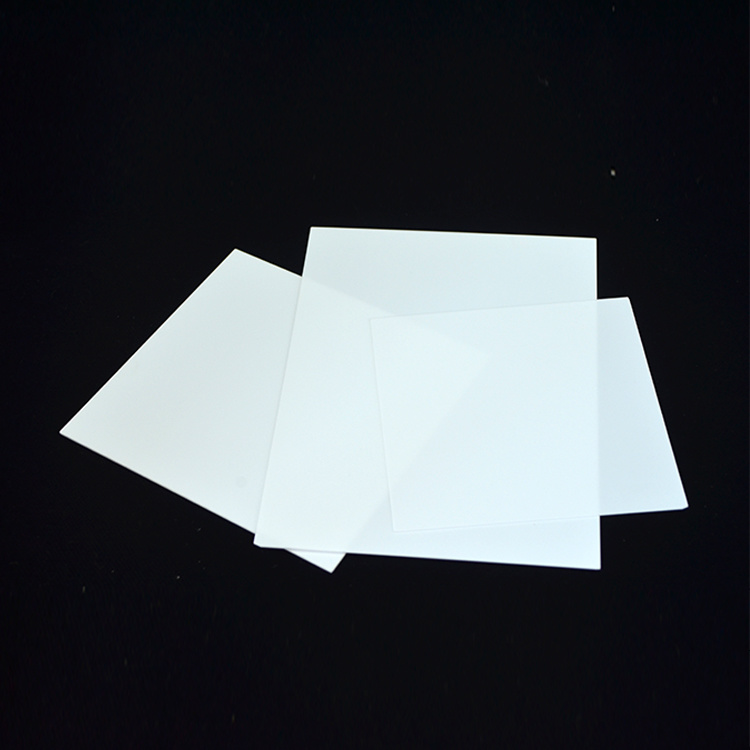

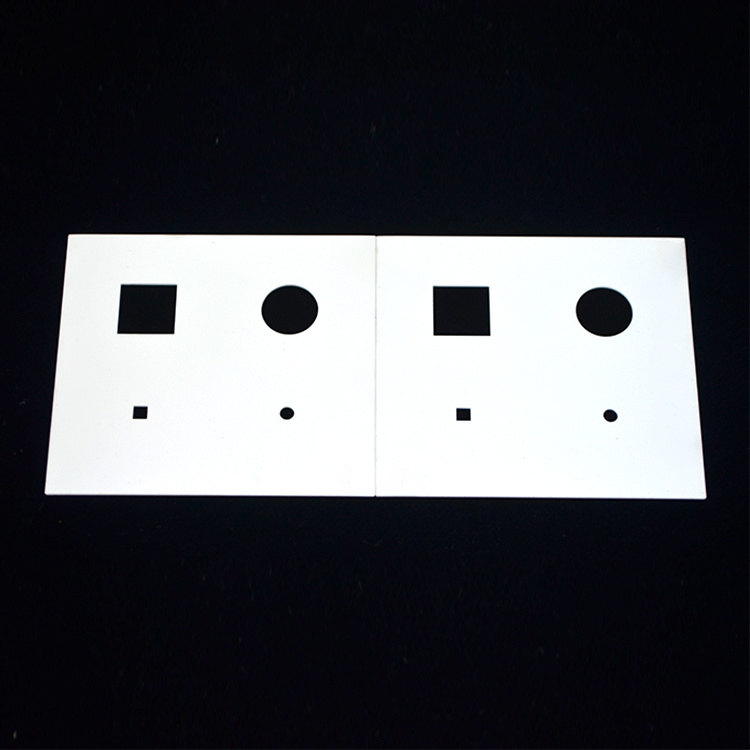

SINTYRON 95% 96% heat sink al2o3 alumina ceramic substrate

High-performance alumina ceramic heat sink substrates, offering excellent thermal conductivity, electrical insulation, and durability for advanced electronic cooling solutions. Ideal for LED, power electronics, and high-heat applications.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

SINTYRON 95% 96% heat sink al2o3 alumina ceramic substrate

Product Overview

Our Heat Sink Alumina Ceramic Substrate is a high-performance thermal management solution

designed for efficient heat dissipation in demanding electronic applications. Made from high-purity

alumina (Al₂O₃), this ceramic substrate offers excellent thermal conductivity, electrical insulation,

and mechanical strength, making it ideal for power electronics, LED modules, semiconductor devices,

and more.

Technical Specifications

Property | Value |

Material | Alumina (Al₂O₃) |

Purity | 96% - 99.6% |

Thermal Conductivity | 24-30 W/m·K |

Dielectric Strength | ≥10 kV/mm |

Operating Temperature | Up to 1600°C |

Available Thickness | 0.5mm - 10mm (customizable) |

Surface Finish | Polished, Metallized (optional) |

Key Features & Benefits

Superior Thermal Conductivity – Efficiently transfers heat away from sensitive components.

High Electrical Insulation – Ensures safe operation in high-voltage environments.

Mechanical Durability – Resistant to thermal shock, corrosion, and wear.

Customizable Thickness & Size – Available in various dimensions to fit your application.

Excellent Dielectric Strength – Ideal for high-frequency and high-power circuits.

Smooth Surface Finish – Optimized for bonding with heat sinks or electronic components.

Applications

Power Electronics (IGBT, MOSFET modules)

LED & Laser Diode Cooling

Automotive & Aerospace Electronics

RF & Microwave Devices

Semiconductor Packaging

Industrial Heating Systems

Why Choose Our Alumina Ceramic Substrate?

High Reliability – Stable performance under extreme conditions.

Custom Solutions – Tailored sizes, shapes, and coatings available.

Fast Lead Time – Quick production and global shipping.

Competitive Pricing – Cost-effective without compromising quality.

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.