PRODUCT CENTER

XING TAL LONG

Recommended Products

SINTYRON Precision Machining Al2O3 Alumina Ceramic Bushing with Flange

Alumina ceramic bushings offer unmatched wear resistance, corrosion immunity, and thermal stability for long-lasting, maintenance-free performance in extreme environments.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

Alumina Ceramic Bushing with Flange

Precision-Machined, High-Wear-Resistant Components for Industrial Applications

Custom OEM/ODM Service – Your Design, Our Expertise

±0.01mm Tolerance – Ultra-Precise Fit for Demanding Applications

99.6% Al₂O₃ Purity – Exceptional Hardness & Corrosion Resistance

Flange Design for Secure Mounting – Enhanced Stability & Load Distribution

Fast Prototyping & Mass Production – 15-Day Standard Lead Time

Product description:

Our Alumina Ceramic Bushing with Flange is engineered for extreme durability in high-stress

environments. Made from 99.6% pure alumina ceramic, it offers superior wear resistance,

thermal stability, and chemical inertness, making it ideal for:

Semiconductor Equipment – Plasma-resistant, ultra-high-vacuum compatible

Laser & Optical Systems – Low thermal expansion, high IR transparency

Pump & Valve Components – Corrosion-proof, long-lasting sealing solutions

Medical & Food Processing – FDA-compliant, non-contaminating

We can do OEM and OBM according to your drawing and requires:

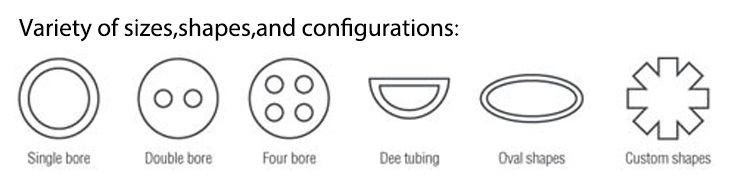

Customization Options

Dimensions: Tailored flange OD/ID, thickness, and bore size

Surface Treatments: Precision grinding, mirror polishing, laser engraving

Special Features: Lubrication grooves, threaded inserts, multi-layer coatings

Certifications: ISO 9001, RoHS, CE

| Composition | AL95 | AL99 |

| AL2O3 Content | 97% | 99.80% |

| Color | White | Ivory |

| Tensile | 30 Kpsi | 32 Kpsi |

| Flexural | 55 Kpsi | 60 Kpsi |

| Compressive | 300 Kpsi | 330 Kpsi |

| Density | 3.7 g/cc | 3.92 g/cc |

| Hardness | 13.8 HV, Gpa | 18 HV, Gpa |

| Thermal Conductivity | 25 W/(m K) | 32 W/(m K) |

| C.O.T.E. | 77 In / In°C (x10^7) | 78 In / In°C (x10^7) |

| Working Temperature | 1500 °C | 1750 °C |

| Dielectric Constant | 9.5 | 9.8 |

| Volume Resistivity | >10^14 Ohm-cm | >10^15 Ohm-cm |

| Dielectric Strength | 16 KV/mm | 20 KV/mm |

Advantages:

High thermal shock resistance

Low thermal conductivity

Chemically inert

Long service life in harsh environments

Customization:

These tubes can be tailored to meet specific requirements, such as:

Different alumina purity levels

Surface finishes (e.g., polished, glazed)

Precision tolerances for bore size and ovality

If you need more details about specific properties, applications, or suppliers,

feel free to ask!

Why Choose Our Porous Alumina Tubes?

Precision Engineered – Consistent pore distribution for reliable performance.

Lab-Tested Durability – Rigorous QC ensures longevity in extreme conditions.

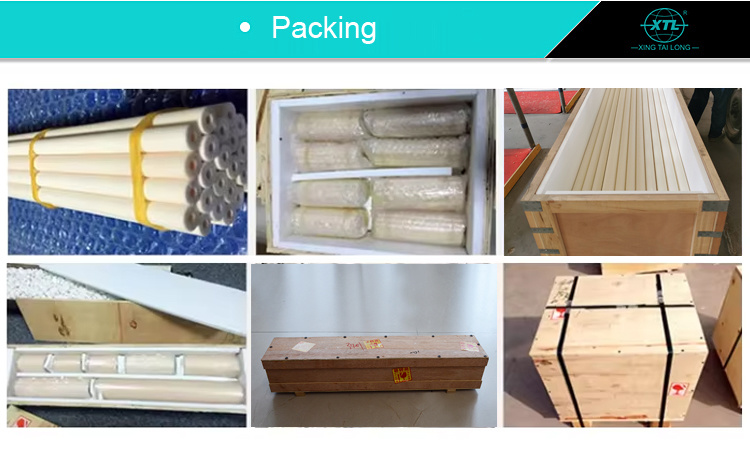

Global Shipping – Fast delivery with OEM/ODM services.

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t

have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.