PRODUCT CENTER

XING TAL LONG

Recommended Products

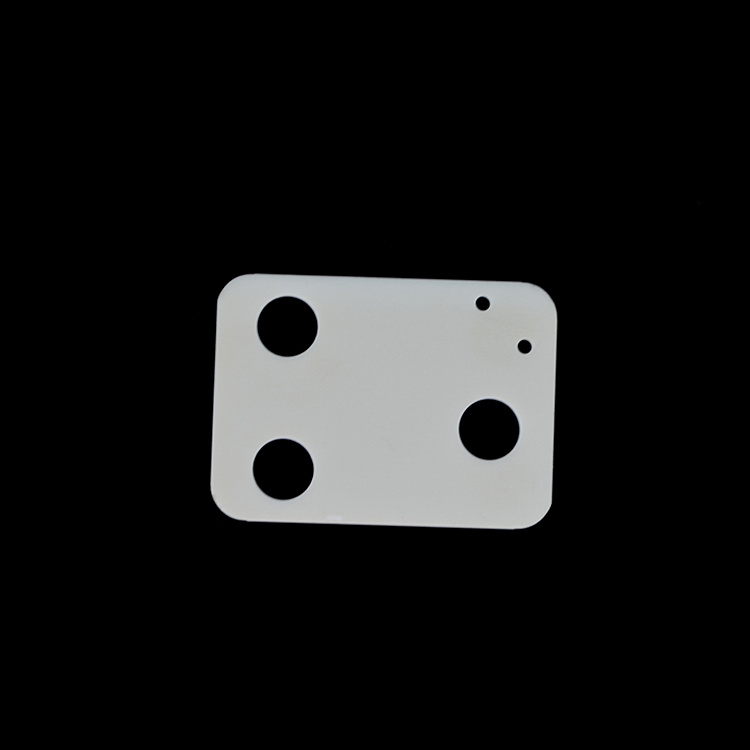

SINTYRON 1500 high temperature square plate 96 alumina ceramic sheet with holes

Alumina ceramic positioning plates are high-performance components crafted from alumina (Al₂O₃) ceramic materials, renowned for their exceptional combination of mechanical, thermal, and chemical properties. These plates are engineered to provide precise positioning and stability in various industrial applications, where accuracy, durability, and resistance to harsh environments are critical.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

SINTYRON 1500 high temperature square plate 96 alumina ceramic sheet with holes

Product description:

Alumina plates, made from aluminum oxide (Al₂O₃), are widely used in various industries due to their excellent properties,

including high hardness, thermal stability, and chemical resistance.

Alumina ceramic substrate Information:

| Product | Alumina ceramic plate |

| Material | Al2O3 |

| Purity | 95%-99% |

| Color | White/Nylon yellow |

| Shape | Arc/Square/Rectangle/Cylinder/Boat |

| Capacity | 1-2000 ml |

| Density | 3.98 g/cm3 |

| Melting Point | 2020℃ |

| Max. Working Temperature | 1800 ℃or 3180 F |

Performance parameters:

| Test item | alumina | |||

| index | unit | AL997 | AL99 | AL95 |

| Principal component content | N/A | 99.70% | 99% | 95% |

| Color | N/A | ivory white | ivory yellow | White |

| Gas permeability | N/A | airtight | airtight | airtight |

| density | g/cm3 | 3.9 | 3.8 | 3.7 |

| hardness | Moh's hardness | 9 | 9 | 8.8 |

| Water Absorption | N/A | ≤0.2 | ≤0.2 | ≤0.2 |

| Bending strength (20°C) | Mpa | 375 | 340 | 304 |

| Compressive Strength (20°C) | Mpa | 2300 | 2210 | 1910 |

| Coefficient of thermal expansion (25°C to 800° C) | 10X6/° C | 7.6 | 7.6 | 7.6 |

| Insulation strength (5mm thickness) | AC-kv/mm | 10 | 10 | 10 |

| Dielectric loss 25°C lMHz | N/A | 0.0001 | 0.0006 | 0.0004 |

| dielectric constant 25°C MHz | N/A | 9.8 | 9.5 | 9.2 |

| Volume resistivity (20°C) (300°C) (500 °C) | Ω.cm3 | >1014 | >1014 | >1014 |

| 2X1012 | 4X10" | 2X10" | ||

| N/A | N/A | N/A | ||

| Long-term service temperature | ℃ | 1700 | 1600 | 1400 |

| Thermal conductivity (25° C) | W/m/K | 35 | 34 | 20 |

Feature of Alumina Plates

-

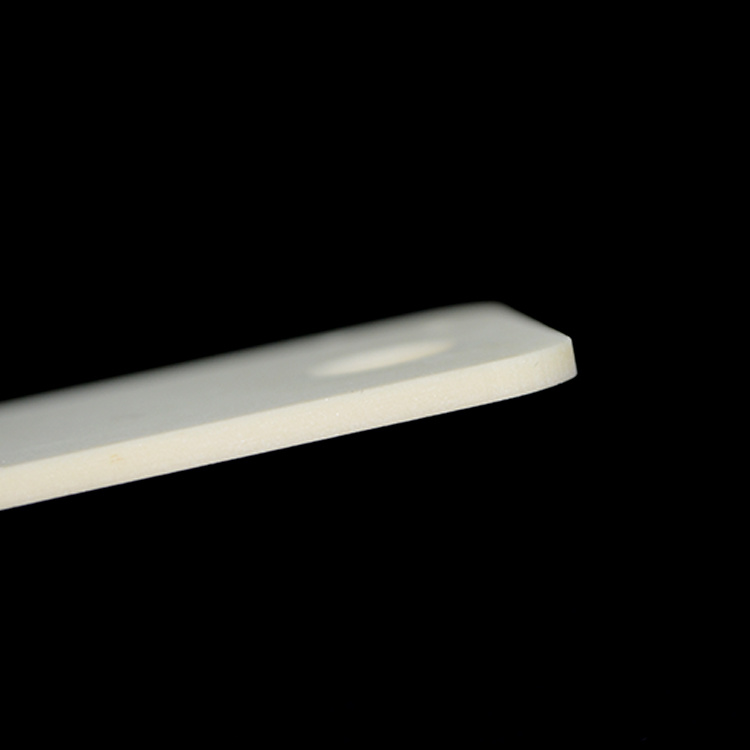

Material: High-purity alumina (96%, 99%, or 99.5% Al₂O₃) for superior mechanical and thermal performance.

-

Dimensional Stability: Maintains tight tolerances (±0.01mm or better) under thermal and mechanical stress.

-

High Wear Resistance: Excellent hardness (~Hv 1500) ensures long-term durability in abrasive environments.

-

Thermal Properties: Withstands temperatures up to 1600°C with minimal expansion.

-

Electrical Insulation: High dielectric strength (>10 kV/mm) prevents current leakage in sensitive applications.

-

Chemical Inertness: Resists acids, alkalis, and corrosive gases, suitable for harsh environments.

-

Surface Finish: Precision grinding/polishing (Ra ≤ 0.2μm) for smooth, burr-free edges.

Applications of Alumina Plates:

-

Industrial Wear Liners: Used in mining, cement, and chemical industries for lining chutes, hoppers, and pipelines

to protect against wear and tear. -

Electronics and Semiconductors: Their thermal and electrical properties make them suitable for use in electronic

substrates and semiconductor components. -

Medical Devices: Alumina plates are used in medical applications due to their biocompatibility and precision.

-

Catalysis and Filtration: Nano-sized alumina plates are used in catalytic applications and as filter plates for

aluminum casting

Manufacturers and Suppliers

-

AdValueTech: Offers alumina plates in various dimensions and thicknesses, with customization options available.

-

CERADIR: Provides 99.7% alumina plates with high reliability and thermal stability, suitable for industrial and

electronic applications. -

MICROPLAN ITALIA: Manufactures precision alumina surface plates with high flatness tolerances, available in custom

sizes and configurations. -

AGILEEN: Supplies high-quality alumina plates with a wide range of sizes and dimensions, suitable for various

industrial applications.

Customization and Quality Assurance

-

Customization: Many manufacturers offer alumina plates tailored to specific dimensions, shapes, and performance requirements

based on customer drawings or samples. -

Quality Control: Manufacturers adhere to strict quality control processes, including ISO certifications, to ensure the plates meet

high standards of durability and performance

Advantages of Alumina Plates

-

Cost-Effective: Despite their advanced properties, alumina plates are competitively priced compared to other high-performance

ceramics. -

Versatility: Suitable for a wide range of industries, including mining, medical, and electronics.

-

Long Service Life: Their wear resistance and toughness ensure a longer lifespan, reducing replacement costs

Company Information:

FAQ:

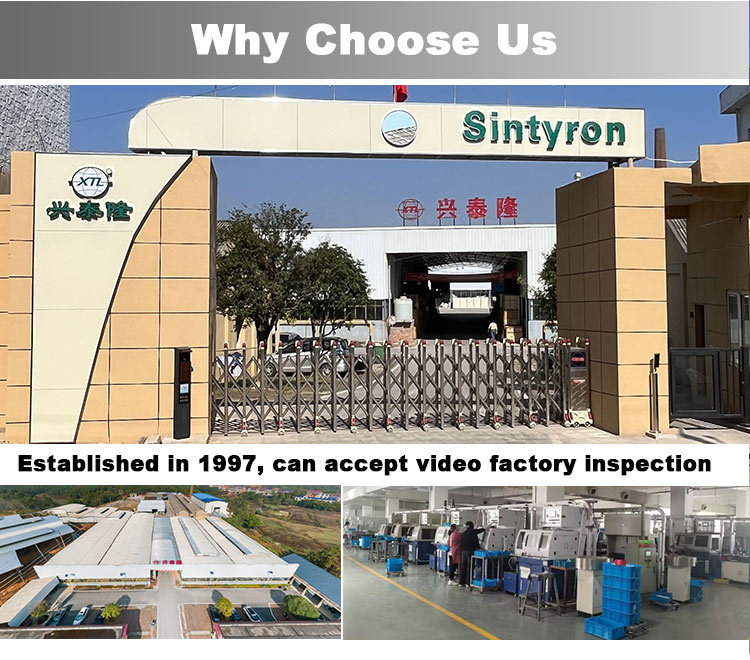

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea,

we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.