PRODUCT CENTER

XING TAL LONG

Recommended Products

SINTYRON Customized High-Polished Zirconia Ceramic Ball Body Valve

High-performance zirconia ceramic rings with flanges offer exceptional strength, wear resistance, and thermal stability, ideal for precision industrial, medical, and aerospace applications.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

SINTYRON Customized High-Polished Zirconia Ceramic Ball Body Valve

Us supply ceramic valve pair valve ball and valve seat with mutli sizes and types for difference pumps.

ceramic valve pair valve ball and valve seat for rod pump, Subsurface pump/Oilfield Tubing pump/Insert

pump, sealing, it is widely used in petroleum industry and other anti-corrosion machine parts.

Properties

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1750°), good

thermal diffusivity, good insulativity, low cost etc.

Main raws of our ceramic valve:

Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc.

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

| Property | Typical Value (3Y-TZP) | Unit | Remarks |

| Yttria Content | 3-8 mol% | - | 3Y-TZP (3 mol%), 8Y-TZP (8 mol%) |

| Density | 5.9 - 6.1 | g/cm³ | Near-theoretical density (>99%) |

| Flexural Strength | 800 - 1200 | MPa | High mechanical strength |

| Compressive Strength | 2000 - 3000 | MPa | Superior to alumina |

| Fracture Toughness (K₁c) | 5 - 10 | MPa·m¹/² | Tougher than most ceramics |

| Vickers Hardness (HV) | 1200 - 1400 | HV | Extremely wear-resistant |

| Young’s Modulus | 200 - 210 | GPa | Stiffer than steel |

| Poisson’s Ratio | 0.30 - 0.32 | - | - |

| Thermal Conductivity | 2 - 3 | W/m·K | Low thermal conductivity |

| Thermal Expansion Coefficient | 10 - 11 (RT-1000°C) | ×10⁻⁶/K | Matches some metals |

| Max. Operating Temperature | Up to 1500°C (short-term) | °C | Long-term use ~1000°C |

| Dielectric Strength | 10 - 15 | kV/mm | Excellent insulator |

| Volume Resistivity (20°C) | >10¹² | Ω·cm | High electrical resistance |

| Oxygen Ion Conductivity (8YSZ, 800°C) | ~0.1 | S/cm | Used in SOFCs |

Application:

Chemical Processing: Handling corrosive and abrasive chemicals, slurries, and pigments.

Petrochemical & Refining: Controlling catalyst streams and other abrasive processes.

Mining and Mineral Processing: Managing abrasive slurries in pipelines and processing plants.

Power Generation: Fly ash handling, FGD (Flue Gas Desulfurization) systems.

Steel & Paper Mills: Handling abrasive process fluids and waste streams.

Pharmaceutical and Food & Beverage: Where purity, cleanliness, and corrosion resistance are critical.

FAQ

Why us?

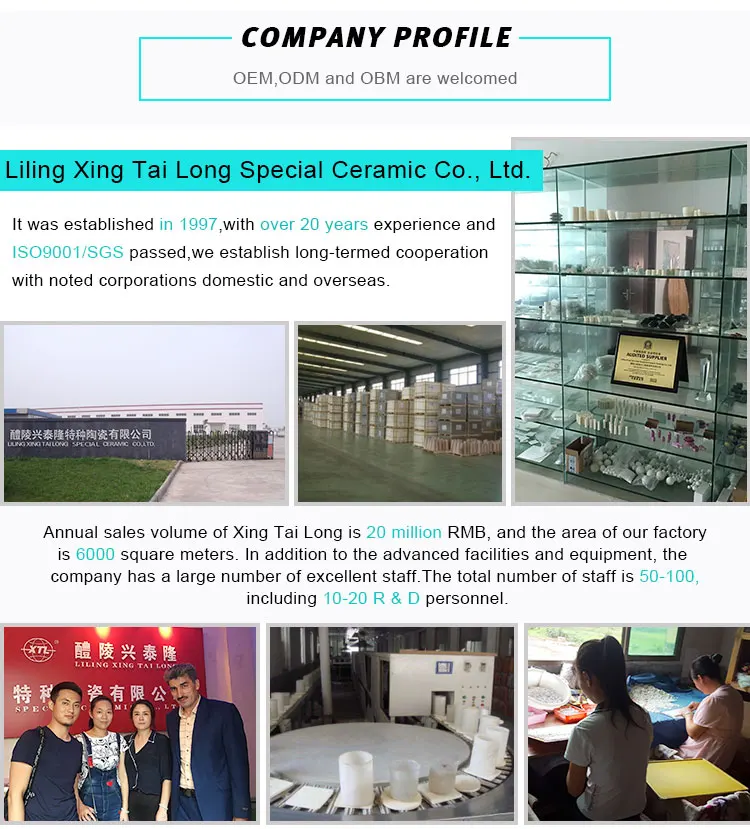

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.