PRODUCT CENTER

XING TAL LONG

Recommended Products

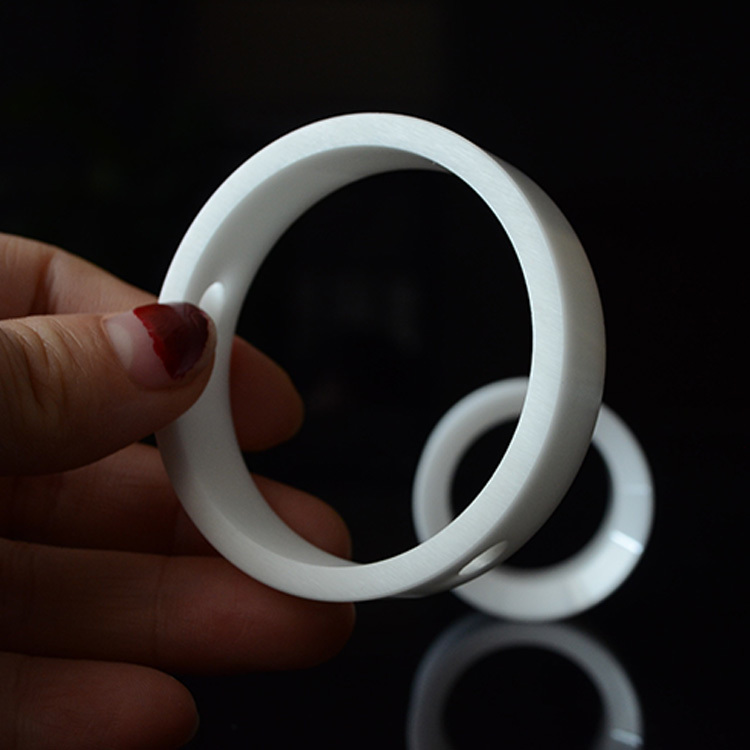

XTL Sintyron Zirconia ceramic rings

zirconia ceramic sealing rings offer a combination of exceptional hardness, wear resistance, chemical stability, and thermal resistance, making them a reliable choice for demanding sealing applications. With their long service life, low maintenance requirements, and excellent performance, zirconia ceramic sealing rings are a cost-effective solution for industries that require high-performance sealing components.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

XTL Sintyron Zirconia ceramic rings

Zirconia ceramic sealing ring is a type of high-performance sealing component made from zirconium dioxide (ZrO2) material. Zirconia ceramics are known for their exceptional hardness, wear resistance, and chemical stability, making them ideal for use in sealing applications where high temperatures, corrosive environments, and extreme conditions are present.

The zirconia ceramic sealing ring is designed to provide a tight and leak-free seal between two mating surfaces, preventing the escape of fluids or gases. It is commonly used in industrial applications such as pumps, valves, compressors, and high-pressure systems where reliable sealing is essential.

One of the key advantages of zirconia ceramic sealing rings is their exceptional hardness and wear resistance. Zirconia ceramics are extremely hard materials, ranking just below diamond in terms of hardness. This allows the sealing ring to withstand the wear and tear of constant use, ensuring a long service life and reduced maintenance costs.

In addition, zirconia ceramics have excellent chemical stability, making them resistant to corrosion and chemical attack. This makes the zirconia ceramic sealing ring suitable for use in harsh environments where other materials may degrade or fail.

Another important characteristic of zirconia ceramic sealing rings is their thermal stability. Zirconia ceramics can withstand high temperatures without losing their strength or dimensional stability, making them ideal for sealing applications where heat resistance is required.

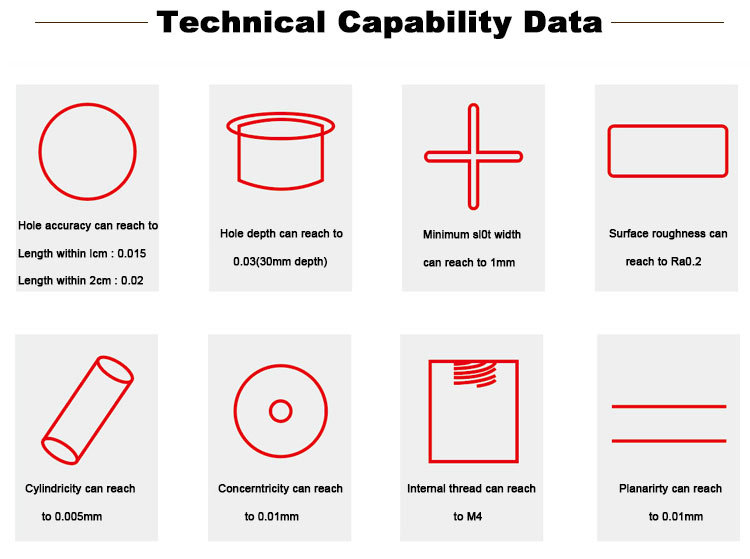

The precision engineering and manufacturing process used to produce zirconia ceramic sealing rings ensure that they have a high degree of dimensional accuracy and tight tolerances. This allows the sealing ring to provide a precise and reliable seal, even under high pressures and extreme conditions.

| Y-FSZ Ceramic Properties | ||

| Chemical content | ZrO2 | 86 wt% |

| Y2O3 | 14 wt% | |

| Physical Properties | Melting point | ≥2500℃ |

| Max. operating temperature | 2200℃ | |

| Color | White | |

| Density | 5.8g/cm3 | |

| Mechanical properties | Flexural strength | 200MPa |

| Young’s module | 200GPa | |

| Hardness(HRA) | 86 | |

| Thermal properties | Thermal expansion coefficient(20℃) | 8-10X10-6 |

| Thermal conductivity | 1-2W/mk | |

| Electrical properties | Dielectric constant(1MHz25℃) | 12 |

| Electrical resistivity(25℃) | 109 | |

FAQ

Why us?

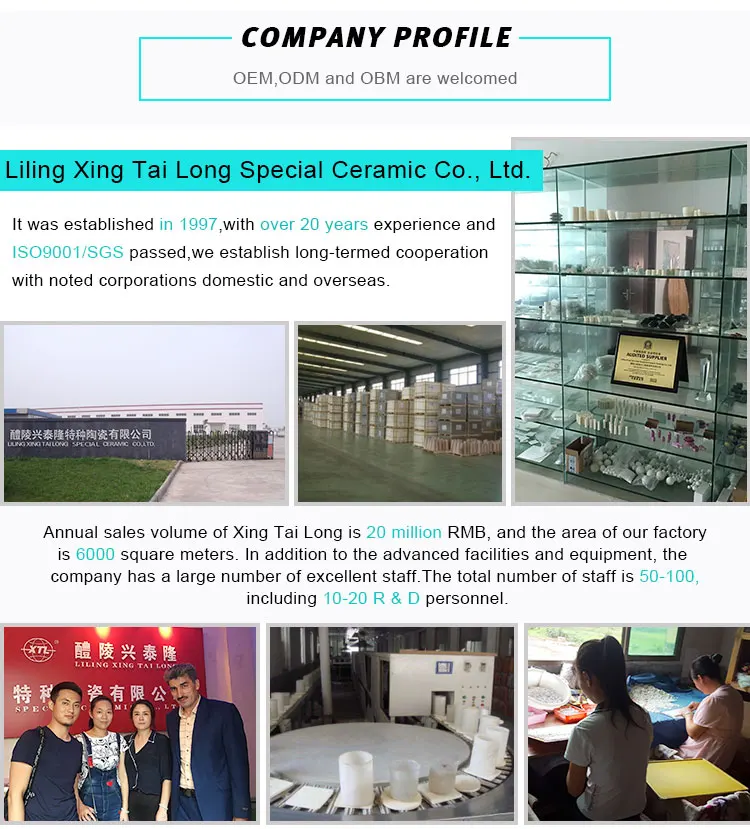

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

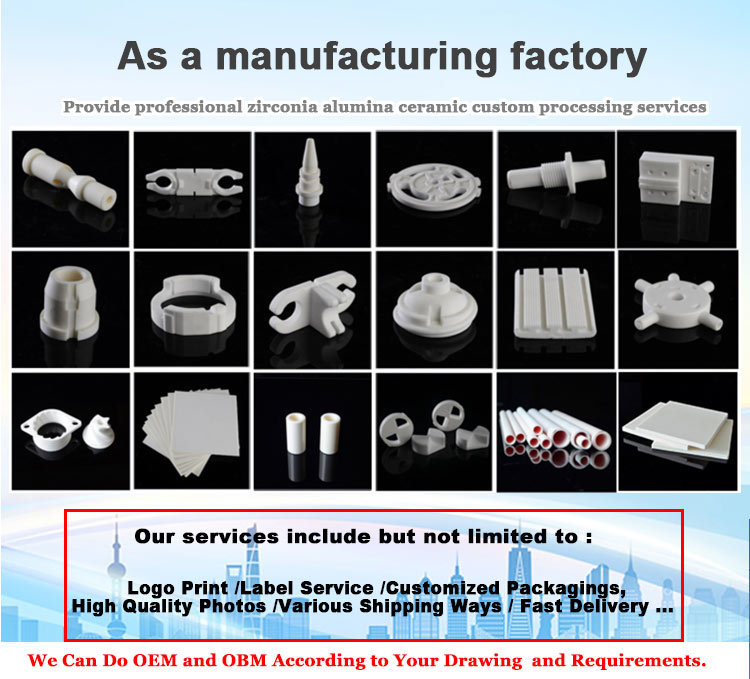

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.