PRODUCT CENTER

XING TAL LONG

Recommended Products

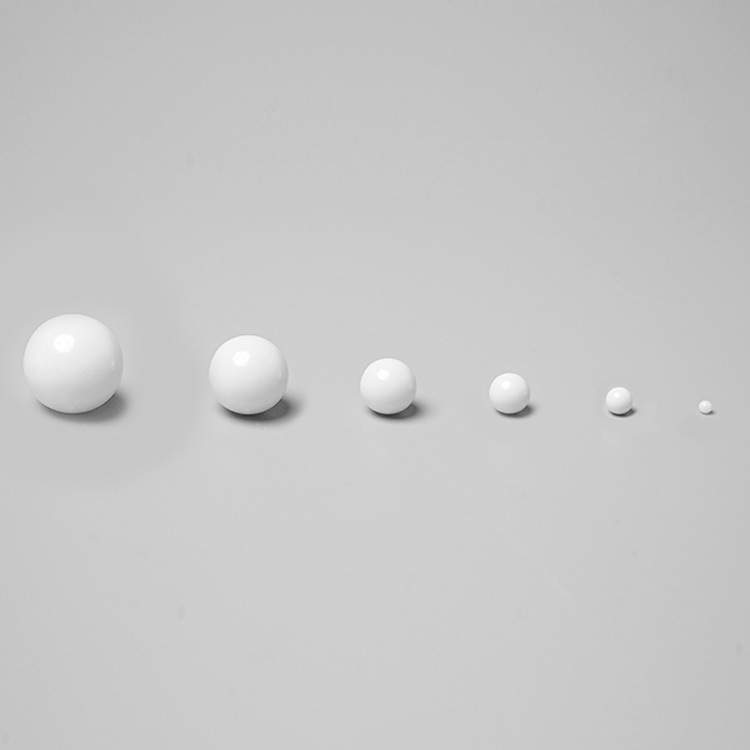

XTL Sintyron Zirconium bead zirconia ceramic grinding media balls for titanium dioxide

zirconia ceramic grinding media balls are a versatile and high-performance grinding media option for a wide range of applications. Their combination of high hardness, wear resistance, and chemical inertness make them ideal for grinding and milling processes where efficiency, quality, and consistency are paramount. Whether you are grinding minerals, pigments, or chemicals, zirconia ceramic grinding media balls can help you achieve the desired results with ease.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

-

Zirconia ceramic grinding media balls are high-quality grinding media balls made of zirconia ceramic material. Zirconia ceramic is a type of ceramic material that is known for its high hardness, wear resistance, and chemical inertness. These properties make zirconia ceramic grinding media balls ideal for use in grinding and milling applications where high efficiency and long-lasting performance are required.

Zirconia ceramic grinding media balls are commonly used in industries such as mining, paint and coating, ceramic, and pharmaceuticals. They are used to grind and disperse materials such as minerals, pigments, and chemicals. The high hardness of zirconia ceramic ensures that the grinding media balls can effectively grind and break down hard and abrasive materials, resulting in a fine and uniform particle size distribution.

One of the key advantages of zirconia ceramic grinding media balls is their high wear resistance. Unlike traditional grinding media balls made of steel or other materials, zirconia ceramic grinding media balls are highly resistant to wear and can last much longer, reducing the need for frequent replacements. This not only saves time and money but also ensures a consistent and efficient grinding process.

In addition to their wear resistance, zirconia ceramic grinding media balls also offer excellent chemical inertness. This means that they will not react with the materials being ground, ensuring that the purity and quality of the final product are maintained. This is particularly important in industries such as pharmaceuticals and food processing where product contamination must be avoided at all costs.

Another advantage of zirconia ceramic grinding media balls is their high density, which results in a higher grinding efficiency. The dense structure of zirconia ceramic allows the grinding media balls to effectively crush and grind materials, resulting in a faster and more efficient grinding process. This can lead to increased productivity and reduced processing times, making zirconia ceramic grinding media balls a cost-effective choice for many industries.

XTL Sintyron Durable Zirconia Ceramic Part For Mechanical

Features

1). Excellent insulation, security, long working life.

2). High temperature resistance

3). Resistance to electric breakdown

4). Stand wear and tear

5). High strength

6). Corrosion resistance

7). Good compactness 8). High hardness

|

material technical indicators item |

Y8 series | 3Y series | FZTA series |

|---|---|---|---|

| ZrO2 content | 90% | 94.5% | 40% |

| Density (g/cm3) | ≥5.9 | ≥6.0 | ≥4.8 |

| Hardness (HV) | >1200 | >1200 | >1200 |

| Bending strength (MPa) | ≥1100 | ≥1000 | ≥600 |

| Elastic modulus (GPa) | 200 | 200 | 180 |

| Thermal conductivity W/m.k | 4 | 3 | 6 |

| Fracture toughness MPa.m | 10 | 8 | 3.5 |

| Corrosion resistance | Superior | average | Superior |

| high temperature wear resistance | Superior | average | average |

| Abrasion resistance at room temperature | Superior | Superior | average |

| fatigue resistance | Superior | average | Superior |

-

Zirconia beads are widely used in various fields due to their excellent properties. In the medical field, they are utilized as dental implants and in orthopedic applications due to their biocompatibility and high strength. In the cosmetic industry, zirconia beads are used in skin care products for exfoliation and rejuvenation. In the field of catalysis, they are utilized as catalyst supports due to their high surface area and stability. Zirconia beads are also commonly used as grinding media in the production of paints, inks, and coatings due to their high hardness and wear resistance. Overall, zirconia beads play a crucial role in a wide range of applications due to their unique combination of properties.

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t

have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.