PRODUCT CENTER

XING TAL LONG

Recommended Products

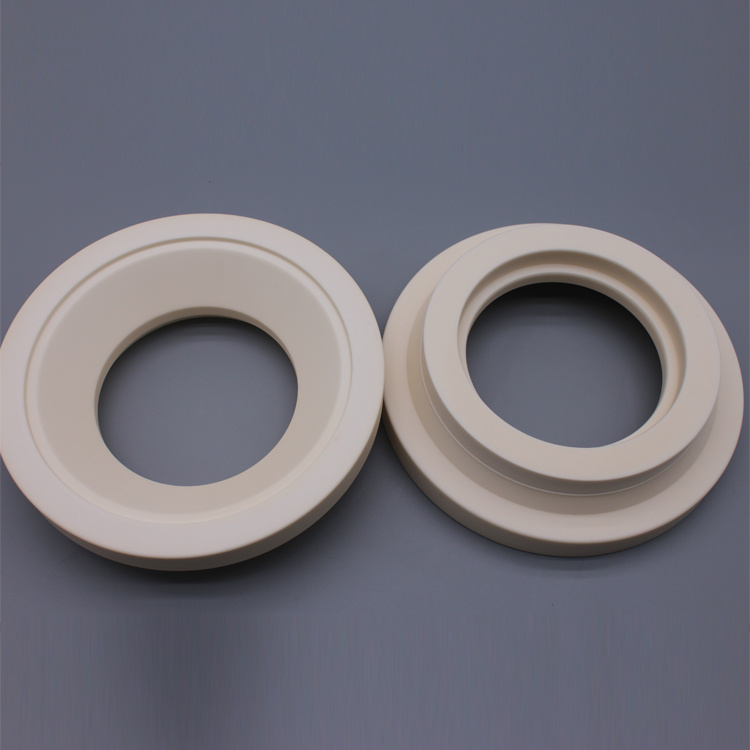

XTL sintyron 99 alumina ceramic flange ring

Alumina ceramic flange ring is a reliable and high-performance component that offers great value in various industrial settings. Its versatility, durability, and resistance to harsh environments make it a popular choice for engineers and manufacturers looking for reliable sealing solutions.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

XTL sintyron 95% 99% 99.5% al2o3 insulator sealing alumina ceramic ring

Alumina ceramic flange ring is a type of ceramic component that is commonly used in industrial applications due to its excellent properties. The ring is made from high-purity alumina ceramic material, which is known for its high temperature resistance, excellent mechanical strength, and superior chemical resistance.

The flange ring is designed with a flat surface on one side and a raised edge on the other, allowing for easy installation and secure connection between two mating parts. It is often used as a seal or gasket in piping systems, valves, and other equipment to prevent leaks and ensure a tight seal.

The alumina ceramic flange ring is also highly resistant to corrosion, wear, and abrasion, making it suitable for harsh operating conditions in industries such as chemical processing, mining, and power generation. Its durability and long lifespan make it a cost-effective solution for many applications.

Physical characteristics:

| Test item | alumina | |||

| index | unit | AL997 | AL99 | AL95 |

| Principal component content | N/A | 99.70% | 99% | 95% |

| Color | N/A | ivory white | ivory yellow | White |

| Gas permeability | N/A | airtight | airtight | airtight |

| density | g/cm3 | 3.9 | 3.8 | 3.7 |

| hardness | Moh's hardness | 9 | 9 | 8.8 |

| Water Absorption | N/A | ≤0.2 | ≤0.2 | ≤0.2 |

| Bending strength (20°C) | Mpa | 375 | 340 | 304 |

| Compressive Strength (20°C) | Mpa | 2300 | 2210 | 1910 |

| Coefficient of thermal expansion (25°C to 800° C) | 10X6/° C | 7.6 | 7.6 | 7.6 |

| Insulation strength (5mm thickness) | AC-kv/mm | 10 | 10 | 10 |

| Dielectric loss 25°C lMHz | N/A | v0.0001 | 0.0006 | 0.0004 |

| dielectric constant 25°C MHz | N/A | 9.8 | 9.5 | 9.2 |

| Volume resistivity (20°C) (300°C) (500 °C) | Ω.cm3 | >1014 | >1014 | >1014 |

| 2X1012 | 4X10" | 2X10" | ||

| N/A | N/A | N/A | ||

| Long-term service temperature | ℃ | 1700 | 1600 | 1400 |

| Thermal conductivity (25° C) | W/m/K | 35 | 34 | 20 |

Alumina Ceramic ring Information:

| Product | alumina ceramic ring |

| Material | alumina |

| Purity | 99% |

| Color | light yellow |

| Shape | Round |

| Density | 3.5g/cm3 |

Alumina ceramic rings are components made from aluminum oxide (Al2O3), a type of advanced ceramic material known for its excellent properties, including high hardness, wear resistance, corrosion resistance, and electrical insulation. These rings find applications in various industries due to their ability to perform well in harsh environments. Some common uses of alumina ceramic rings include:

1. Mechanical Seals: In pumps, compressors, and other machinery where they provide a durable, non-conductive, and wear-resistant sealing surface.

2. Insulators: In electrical applications where they serve as high voltage insulators, resisting electrical current flow while withstanding high temperatures.

3. Jewelry: As an alternative to metal, offering a sleek, lightweight, and hypoallergenic option.

4. Aerospace: In engine components and high-temperature applications due to their ability to maintain stability across a wide temperature range.

5. Chemical Processing: As parts in valves and reactors where they come into contact with corrosive chemicals.

6. Medical Devices: In implants and instruments due to their biocompatibility and durability.

Manufacturers often customize alumina ceramic rings to specific dimensions and tolerances depending on the intended use, and they can be finished with polished, ground, or textured surfaces. The purity of alumina used also varies, with higher purity grades offering enhanced properties but at a greater cost.

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service.Just send us your drawing if you have it.If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity.We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.