PRODUCT CENTER

XING TAL LONG

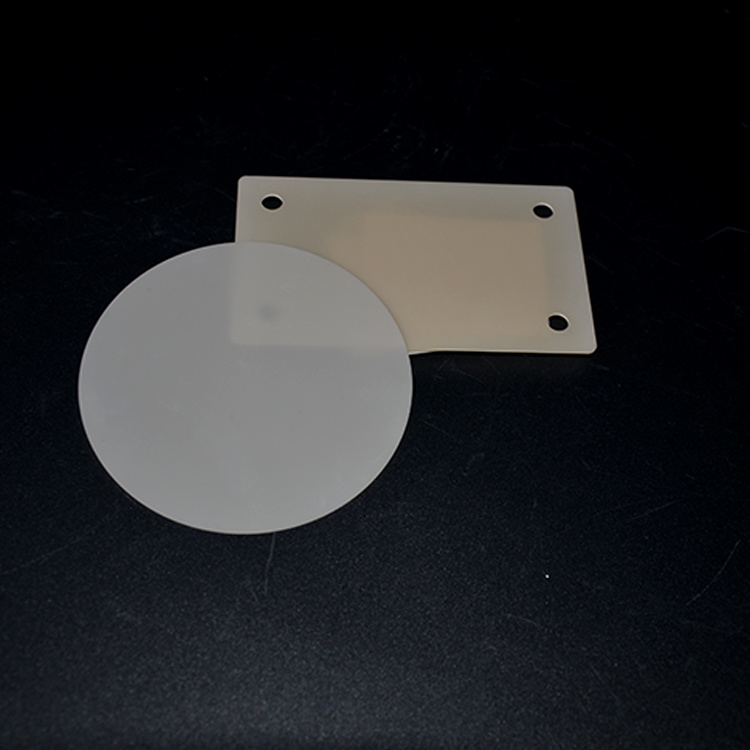

XTL sintyron electrical insulating ceramic aluminium nitride sheet

aluminum nitride substrates offer a combination of thermal conductivity, electrical insulation, and wide bandgap that make them a versatile choice for a wide range of applications in the electronics and optoelectronics industries. With their excellent thermal properties, high electrical insulation, and wide bandgap, AlN substrates are well-suited for demanding applications that require high performance and reliability.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

XTL sintyron electrical insulating ceramic aluminium nitride sheet

Brief introduction

Liling Xingtailong Special Ceramics use their own research and development of high quality aluminum nitride

powder as raw material, using casting method to produce aluminum nitride substrate.

This wafer type product can be metallized to make a part of a high thermal conductivity circuit board,

or can be directly used as an insulation sheet after laser cutting.

Class

Liling Xingtailong special ceramics provide different surface treatment options to meet the diversified needs of customers

instant burning substrate: the flatness and roughness of the substrate after sintering can meet the technical requirements,

and there is no need to do special treatment.

Abrasive substrate: The substrate is ground after sintering to achieve a higher level of flatness and roughness.

Polished substrate: The surface of the substrate after sintering is polished to achieve a mirror effect.

Product descritption:

One of the key advantages of using aluminum nitride as a substrate material is its high thermal conductivity.

With a thermal conductivity of around 170 W/mK, AlN outperforms traditional substrate materials such as

alumina and silicon carbide, making it an excellent choice for highpower electronic devices that generate a

significant amount of heat. This high thermal conductivity allows for efficient heat dissipation, which is

crucial for the reliability and performance of electronic components.

Performance For Industrial Ceramic

|

Item |

Unit |

Our standard | |

|

Appearance |

Color |

- |

Gray / Beige |

|

|

Microstructure |

- |

Dense and fine grain |

|

|

SurfaceRoughness() |

μm |

0.46 |

|

|

Warpage |

‰ |

<2.5 |

|

Physical |

Water Absorption |

% |

0.061 |

|

|

Vickers Hardness |

GPa |

12 |

|

|

Young Modulus |

GPa |

330 |

|

|

VolumeDensity |

g/Cm3 |

≥3.24 |

|

|

BendingStrength |

[3-point Method]MPa |

>350 |

|

Thermal |

@20℃ThermalConductivity |

[@20℃]W/m·k |

≥170 |

|

|

CoefficientofLinear Expansion |

RT-300℃]10-6mm/℃ |

4.6 |

|

Electrical |

Volume Resistance |

Ω·cm |

1.5×1013 |

|

|

[@1MHz] Dielectric Constant |

- |

10.6 |

|

|

[@1MHz] Dielectric Loss |

- |

4.6×10-4 |

|

|

Dielectric Strength |

(KV/mm) |

≥20 |

Aluminum Nitride sheet feature:

Properties:

-

Thermal Conductivity: AlN has a high thermal conductivity (around 170-200 W/m·K), making it an excellent choice for heat dissipation in high-power electronic devices.

-

Electrical Insulation: It is an electrical insulator with a high dielectric strength, making it suitable for use in electronic circuits.

-

Thermal Expansion: AlN has a thermal expansion coefficient close to that of silicon, which minimizes thermal stress when used with silicon-based devices.

-

Mechanical Strength: It possesses good mechanical strength and hardness, making it durable and resistant to wear.

-

Chemical Stability: AlN is chemically stable and resistant to many corrosive environments.

Applications:

-

LEDs: AlN substrates are used in high-power LED applications due to their ability to efficiently dissipate heat.

-

Power Electronics: They are used in power modules and RF/microwave applications where thermal management is critical.

-

Semiconductor Devices: AlN substrates are used in the fabrication of semiconductor devices, including high-electron-mobility transistors (HEMTs) and laser diodes.

-

Thermal Management: They are employed in heat sinks and other thermal management solutions for electronic components.

-

Optoelectronics: AlN is used in optoelectronic devices due to its transparency in the ultraviolet (UV) range.

Fabrication:

-

Sintering: AlN substrates are typically produced by sintering aluminum nitride powder at high temperatures.

-

Thin Films: AlN thin films can be deposited using techniques such as chemical vapor deposition (CVD) or physical vapor deposition (PVD) for specific applications.

Advantages:

-

High Thermal Conductivity: Efficient heat dissipation.

-

Electrical Insulation: Suitable for electronic applications.

-

Thermal Expansion Matching: Reduces thermal stress in electronic assemblies.

-

Durability: High mechanical strength and chemical stability.

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.