PRODUCT CENTER

XING TAL LONG

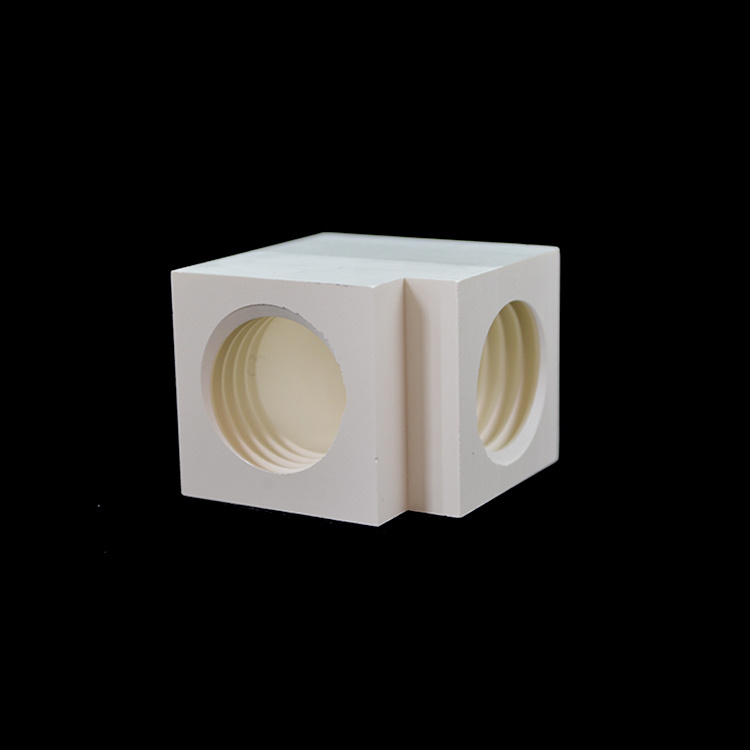

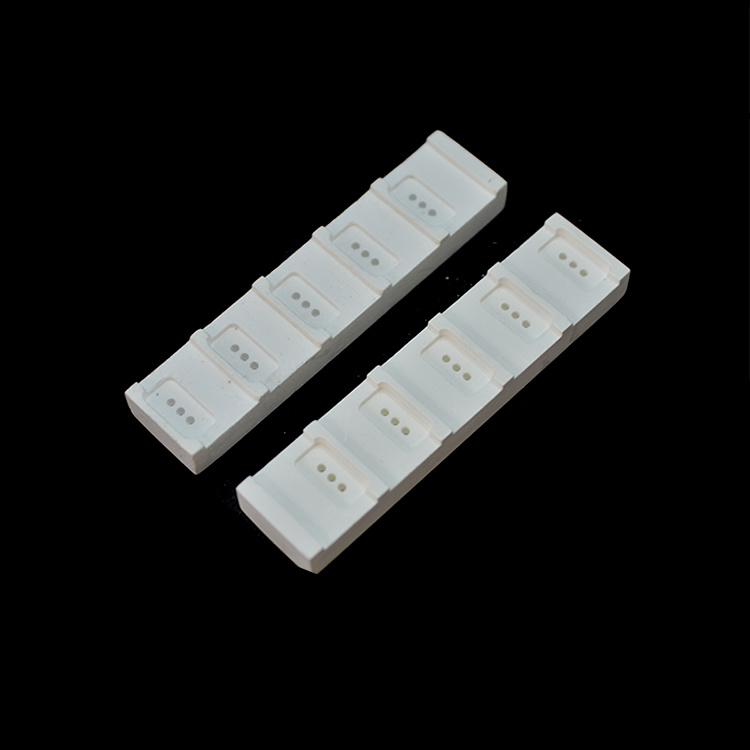

XTL sintyron 99.7% boron nitride ceramic parts

boron nitride parts are versatile components with applications ranging from electronics to high-temperature industrial processes. Their unique combination of thermal, electrical, and mechanical properties makes them indispensable in many advanced technologies.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

XTL sintyron 99.7% boron nitride ceramic parts

Product Instruction

Boron nitride (BN) parts are widely used in various industries due to their unique properties, such as high thermal

conductivity, excellent thermal shock resistance, low thermal expansion, and electrical insulation.

| Item | Unit | Index | |

| Thermal Conductivity (RT) | W/m·k | 40-50 | |

| Thermal expansivity(25-700) | 10-6 °C | 6.5-7.5 | |

| Resistivity (RT) | Ω·m | >1012 | |

| Puncture voltage | 10-6 /kv·m | 2.5-4.0 | |

| Mohs' hardnees | / | 2 | |

| Dielectric constant (Σ) | / | 3.8-4.3 | |

| Bending strength (RT) | mpa | >35 | |

| Compression strength (RT) | mpa | >200 | |

| Density | g/cm3 | 1.9-2.2 | |

| Chemical Composition | B+N | % | 99.5 |

| Oxygen Content | % | <0.4 | |

| Carbon Content | % | <0.02 | |

| Working Environment Temperature | Oxidizing Atmosphere | ℃ | 850 |

| Vacuum | ℃ | 1800 | |

| Inertia | ℃ | 2300 | |

1. Types of Boron Nitride Parts

Boron nitride exists in several crystalline forms, each with distinct properties and applications:

Hexagonal Boron Nitride (h-BN): Often referred to as "white graphite," h-BN is the most common form.

It is machinable, has a layered structure, and is used in applications requiring thermal management and lubrication.

Cubic Boron Nitride (c-BN): Known for its extreme hardness, c-BN is used in cutting tools and abrasives.

It is second only to diamond in hardness and is ideal for machining ferrous materials.

Wurtzite Boron Nitride (w-BN): This form is less common but is used in specialized

applications like steel polishing and high-pressure environments.

2. Applications of BN Parts

BN parts are utilized in a wide range of industries due to their exceptional properties:

Electronics: BN is used as a dielectric layer in field-effect transistors (FETs), photoelectric devices, and UV detectors.

Its high thermal conductivity makes it suitable for heat sinks and substrates in semiconductor processing.

Aerospace and Ceramics: BN parts are used in furnace fixtures, insulators, seals, and brazing fixtures. They are

also employed in glass-forming tools and induction heating components.

High-Temperature Environments: BN crucibles and coatings are used in vacuum melting, vapor deposition,

and other high-temperature processes. They can withstand temperatures up to 2000°C in inert atmospheres.

Lubrication and Release Coatings: BN coatings, such as the LUBRICOAT series, provide non-wetting and non-stick

properties for molds and surfaces exposed to molten metals.

3. Manufacturing Processes

BN parts are produced using various techniques, depending on the desired properties and applications:

Hot Pressing: This method is used to produce machinable h-BN parts. The material is pressed at high temperatures,

resulting in a solid with anisotropic properties.

Chemical Vapor Deposition (CVD): CVD is used to create high-purity pyrolytic BN with excellent mechanical and electrical

properties. This method is ideal for producing thin films and coatings.

Sol-Gel Method: This technique is used to create uniform BN films and coatings. It is cost-effective but less scalable compared to CVD.

Machining: BN parts can be machined into complex shapes with tight tolerances. CNC turning, milling, and grinding are commonly used

to produce components like wafers, crucibles, and insulators

Properties of BN Parts

Thermal Conductivity: BN has high thermal conductivity, making it ideal for heat dissipation in electronic and high-temperature applications.

Electrical Insulation: BN is an excellent electrical insulator, with a dielectric strength of nearly 2300 volts per mil.

Chemical Inertness: BN is resistant to most chemicals and molten metals, making it suitable for use in corrosive environments.

Machinability: h-BN can be easily machined into complex shapes without requiring additional heat treatment.

Product details

Why choose us

Liling Xingtailong Special Ceramic Co., Ltd Founded in 1997, is an independent R&D and manufacturing enterprise integrating

scientific research and production. "Superior quality, preferential price" is our business purpose. The company mainly produces

PBN and BN products. Over the years, the company has been deeply involved in development, and has successively obtained

(ISO9001, Alibaba's ten-year-old high-quality supplier, China Manufacturing Network certified supplier, high-tech enterprise

certification, gold product enterprise certification, ceramic industry AAA credit unit,product ROHS testing certification, and

6 invention patents. The company has always adhered to the goal of quality survival, innovative development, honest brand,

and meticulous and thoughtful after-sales service. Region, product quality and service are highly recognized by customers.

Striving to be Stronger, hard work and progress. The company initiates a professional responsible person model, continuously

improves and innovates, and strives to provide each customer with better and more efficient services. With strong strength,

reasonable price and professional service, We has established long-term cooperative relations with large enterprises at home

and abroad. "Excellent quality, preferential price" is our business purpose. We sincerely look forward to cooperating with more

domestic and foreign customers and developing together.

Customer feedback

FAQ

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t

have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.