PRODUCT CENTER

XING TAL LONG

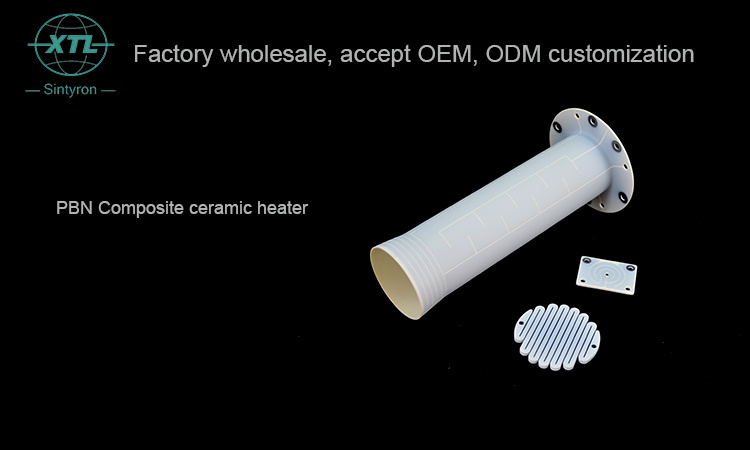

XTL sintyron High Purity 99.99% Pyrolytic Boron Nitride substrate PBN Heating element Heater

PBN-PG Composite Heater is a high-performance heating element that combines Pyrolytic Boron Nitride (PBN) and Pyrolytic Graphite (PG) to create a substrate with exceptional thermal, mechanical, and chemical properties.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

XTL sintyron High Purity 99.99% Pyrolytic Boron Nitride substrate PBN

Heating element Heater

Product Instruction

PBN-PG composite heater is manufactured using the Chemical Vapor Deposition (CVD) process, which ensures high purity

and excellent performance. The substrate consists of a layered structure, typically PBN-PG-PBN, where PBN acts as an

insulating layer and PG serves as the resistive heating element. This combination provides superior thermal conductivity,

thermal shock resistance, and chemical inertness, making it ideal for high-temperature applications

| Item | Unit | Index | |

| Thermal Conductivity (RT) | W/m·k | 40-50 | |

| Thermal expansivity(25-700) | 10-6 °C | 6.5-7.5 | |

| Resistivity (RT) | Ω·m | >1012 | |

| Puncture voltage | 10-6 /kv·m | 2.5-4.0 | |

| Mohs' hardnees | / | 2 | |

| Dielectric constant (Σ) | / | 3.8-4.3 | |

| Bending strength (RT) | mpa | >35 | |

| Compression strength (RT) | mpa | >200 | |

| Density | g/cm3 | 1.9-2.2 | |

| Chemical Composition | B+N | % | 99.5 |

| Oxygen Content | % | <0.4 | |

| Carbon Content | % | <0.02 | |

| Working Environment Temperature | Oxidizing Atmosphere | ℃ | 850 |

| Vacuum | ℃ | 1800 | |

| Inertia | ℃ | 2300 | |

Characteristics of PBN Substrate

-

Thermal Properties:

-

High thermal conductivity and excellent temperature uniformity due to the surface heating properties of

PG and the thermal conductivity of PBN. -

Operates at temperatures exceeding 1500°C, with some designs capable of reaching 1600°C.

-

Low thermal mass and fast thermal response, enabling precise temperature control.

-

-

Mechanical Properties:

-

High mechanical durability and dimensional stability, even under extreme thermal gradients .

-

Excellent thermal shock resistance, allowing rapid heating and cooling without damage.

-

-

Chemical Properties:

-

Chemically inert to most metals, acids, alkalis, and organic solvents, making it suitable for corrosive

environments. -

Minimal gas release at high temperatures, ensuring high-purity conditions for sensitive processes.

-

-

Electrical Properties:

-

PBN provides electrical insulation, while PG acts as the resistive heating element, enabling efficient

and safe operation.

-

Applications of PBN Composite Heater Substrate

The PBN-PG composite heater is widely used in industries requiring high-temperature and high-purity

environments, including:

-

Semiconductor Manufacturing:

-

Rapid annealing furnaces for wafer processing.

-

Molecular Beam Epitaxy (MBE) for producing Gallium Arsenide epitaxial wafers.

-

Sputter coating and metal evaporation processes.

-

-

Research and Analysis:

-

Heating elements in electron microscopes for sample analysis.

-

Superconductor substrate heating.

-

-

Advanced Materials Processing:

-

MOCVD (Metal-Organic Chemical Vapor Deposition) heaters.

-

High-temperature furnaces for crystal growth and material synthesis

-

Advantages Over Other Materials

-

Compared to Graphite Heaters: PBN heaters offer longer service life, better thermal uniformity,

and higher purity, making them ideal for semiconductor and photovoltaic applications. -

Compared to Traditional Ceramics: PBN heaters provide superior thermal shock resistance and

corrosion resistance, ensuring reliability in harsh environments

Product details

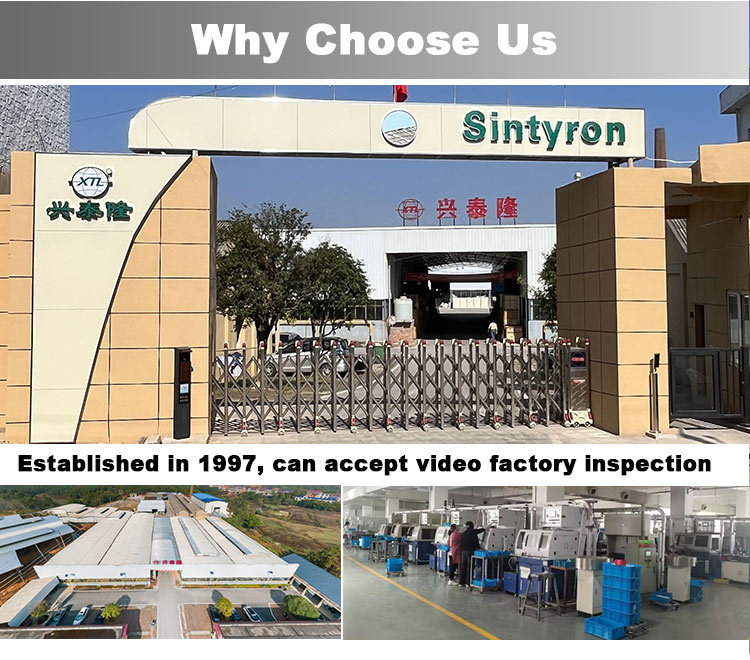

Why choose us

Liling Xingtailong Special Ceramic Co., Ltd Founded in 1997, is an independent R&D and manufacturing

enterprise integrating scientific research and production. "Superior quality, preferential price" is our business

purpose. The company mainly produces PBN and BN products. Over the years, the company has been deeply

involved in development, and has successively obtained (ISO9001, Alibaba's ten-year-old high-quality supplier,

China Manufacturing Network certified supplier, high-tech enterprise certification, gold product enterprise

certification, ceramic industry AAA credit unit,product ROHS testing certification, and 6 invention patents.

The company has always adhered to the goal of quality survival, innovative development, honest brand,

and meticulous and thoughtful after-sales service. Region, product quality and service are highly recognized

by customers. Striving to be Stronger, hard work and progress. The company initiates a professional responsible

person model, continuously improves and innovates, and strives to provide each customer with better and more

efficient services. With strong strength,reasonable price and professional service, We has established long-term

cooperative relations with large enterprises at home and abroad. "Excellent quality, preferential price" is our business

purpose. We sincerely look forward to cooperating with more domestic and foreign customers and developing together.

Customer feedback

FAQ

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t

have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.