PRODUCT CENTER

XING TAL LONG

Recommended Products

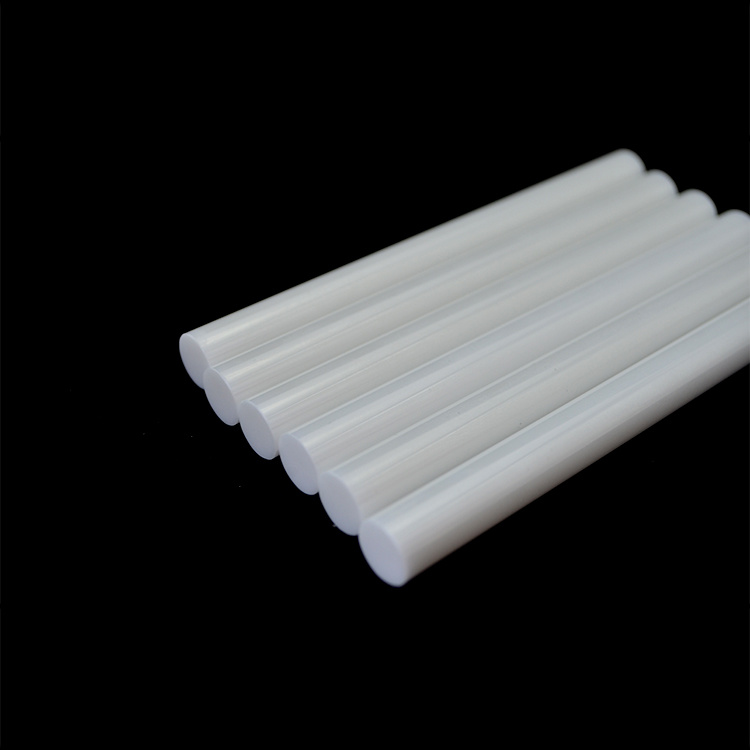

XTL Sintyron custom wear and corrssion resistant ceramic zirconia ceramic bar rod

When selecting a zirconia ceramic rod, consider the following specifications: Diameter and length. Surface finish (e.g., polished, ground). Tolerance levels. Stabilizer type (e.g., YSZ, MSZ, CSZ). Application environment (e.g., temperature, chemical exposure).

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

XTL Sintyron custom wear and corrssion resistant ceramic zirconia ceramic bar rod

A zirconia ceramic rod is a cylindrical component made from zirconium dioxide (ZrO₂), a

high-performance ceramic material known for its exceptional mechanical, thermal, and chemical

properties. Zirconia rods are used in a wide range of applications where high strength, wear resistance,

and thermal stability are required. Below are the key features, applications, and advantages of

zirconia ceramic rods:

Key Features of Zirconia Ceramic Rods

High Mechanical Strength:

Zirconia has excellent flexural and compressive strength, making it suitable for high-stress

applications.

Exceptional Toughness:

Zirconia is one of the toughest ceramic materials, with high fracture resistance compared

to other ceramics like alumina.

Wear and Abrasion Resistance:

Zirconia rods are highly resistant to wear, making them ideal for applications involving friction

and mechanical contact.

Thermal Stability:

Zirconia can withstand high temperatures and thermal shock, making it suitable for use in

extreme environments.

Corrosion Resistance:

Zirconia is chemically inert and resistant to most acids, alkalis, and other corrosive substances.

Low Thermal Conductivity:

Zirconia has low thermal conductivity, making it an excellent thermal insulator.

Electrical Insulation:

It is an excellent electrical insulator, even at high temperatures.

Biocompatibility:

Zirconia is biocompatible, making it suitable for medical and dental applications.

| Y-FSZ Ceramic Properties | ||

| Chemical content | ZrO2 | 86 wt% |

| Y2O3 | 14 wt% | |

| Physical Properties | Melting point | ≥2500℃ |

| Max. operating temperature | 2200℃ | |

| Color | White | |

| Density | 5.8g/cm3 | |

| Mechanical properties | Flexural strength | 200MPa |

| Young’s module | 200GPa | |

| Hardness(HRA) | 86 | |

| Thermal properties | Thermal expansion coefficient(20℃) | 8-10X10-6 |

| Thermal conductivity | 1-2W/mk | |

| Electrical properties | Dielectric constant(1MHz25℃) | 12 |

| Electrical resistivity(25℃) | 109 | |

FAQ

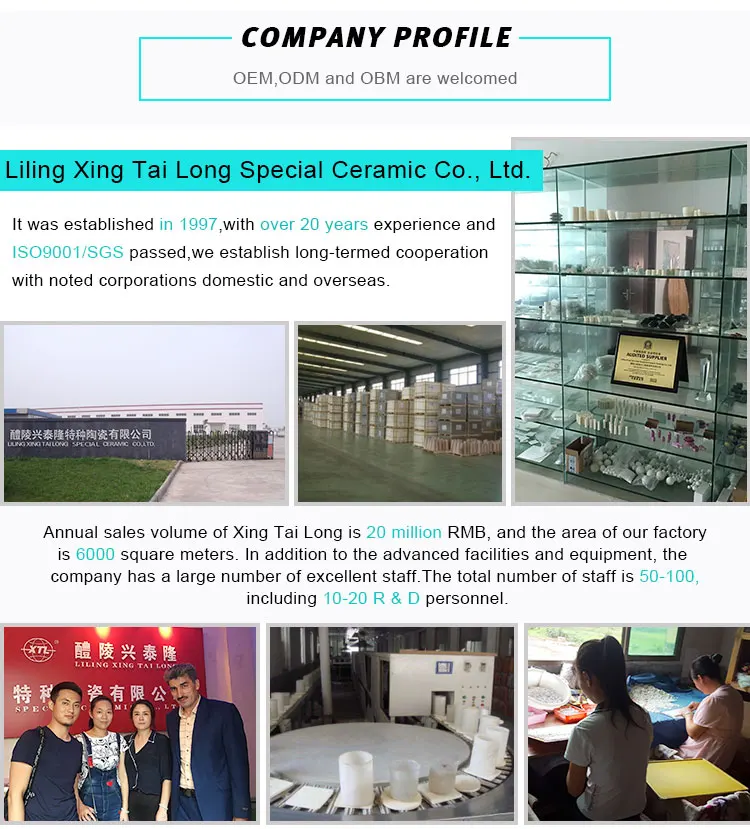

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.