PRODUCT CENTER

XING TAL LONG

Recommended Products

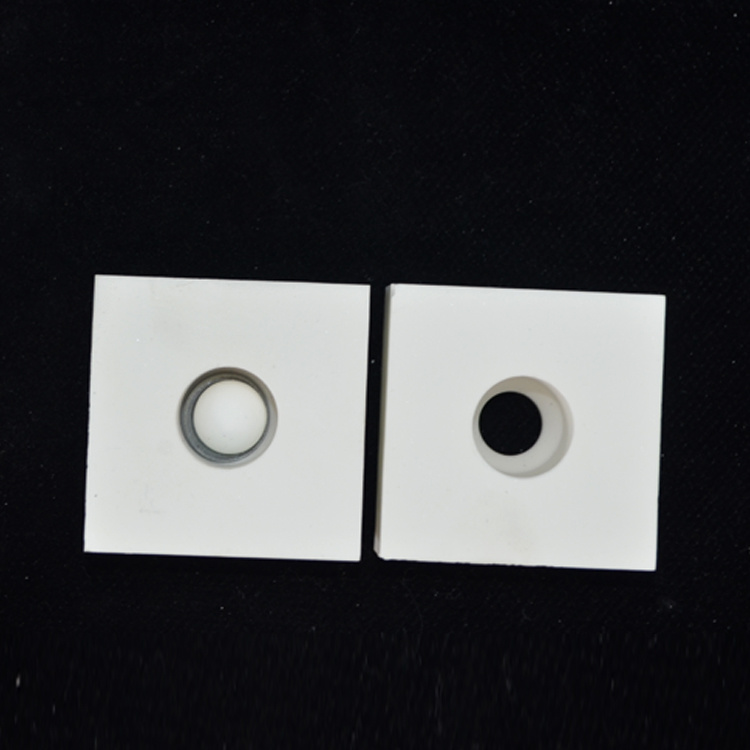

XTL Sintyron 92% 95% high alumina wear resistant ceramic tile brick plate lining

Alumina lining plates are an ideal solution for industries seeking to enhance equipment durability and performance in abrasive or corrosive environments. Let me know if you need further details!

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

XTL Sintyron 92% 95% high alumina wear resistant ceramic tile brick plate lining

Product description:

Specification :

Key Features:

High Wear Resistance: Excellent for extending the lifespan of equipment in abrasive environments.

Impact Resistance: Withstands heavy impacts and mechanical stress.

Corrosion Resistance: Resistant to chemicals and corrosive substances.

High Temperature Tolerance: Can operate in high-temperature environments.

Lightweight: Compared to metal liners, alumina plates are lighter, reducing equipment load.

Design and Installation:

Available in various shapes (rectangular, square, trapezoidal) and thicknesses (typically 5-20 mm).

Can be attached to equipment surfaces using adhesives, bolts, or welding (with embedded metal backing).

Customizable to fit specific equipment dimensions.

| TYPE | High Alumina Lining Brick HASLB 90 | High Alumina Lining Brick HASLB 92 | High Alumina Lining Brick MZALB 80 | High Alumina Lining Brick MHALB 75 |

| Al2O3(%)+Zro2(%) | 90 | 92 | 80 | 75 |

| Bulk Density (g/cm³) | ≥3.65 | ≥3.65 | ≥3.40 | ≥3.25 |

| Water Absorption (%) | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Hardness (Mohs) | 9 | 9 | 9 | 8 |

| Colour | white | white | white | white |

Applications:

Mining and Mineral Processing: Chutes, hoppers, and conveyor systems.

Cement Industry: Raw mill liners, cyclones, and pipelines.

Power Plants: Coal handling and ash disposal systems.

Steel Industry: Blast furnaces and sinter plants.

Chemical Industry: Equipment exposed to corrosive materials.

Advantages:

Significantly reduces downtime and maintenance costs.

Improves operational efficiency by minimizing material buildup.

Longer service life compared to traditional metal liners.

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.