PRODUCT CENTER

XING TAL LONG

Recommended Products

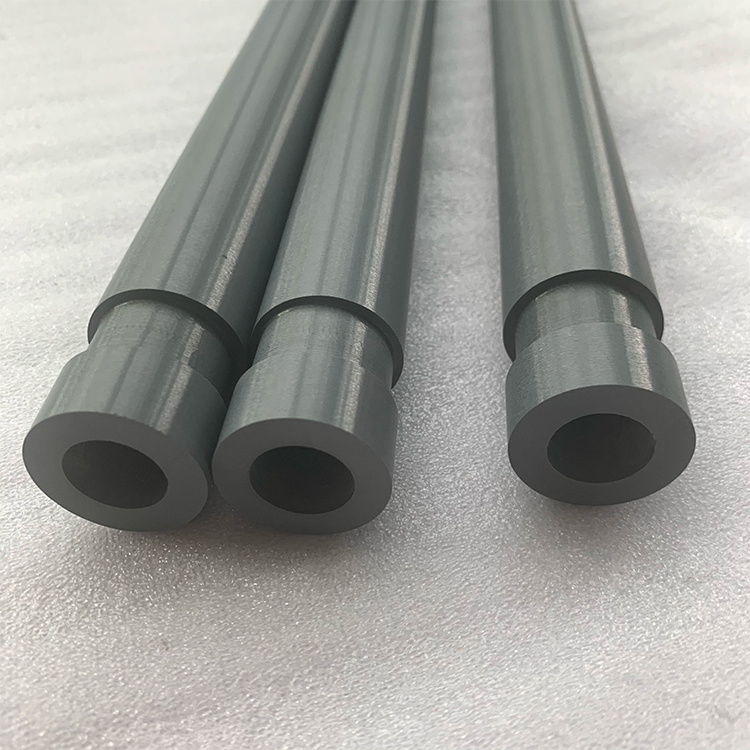

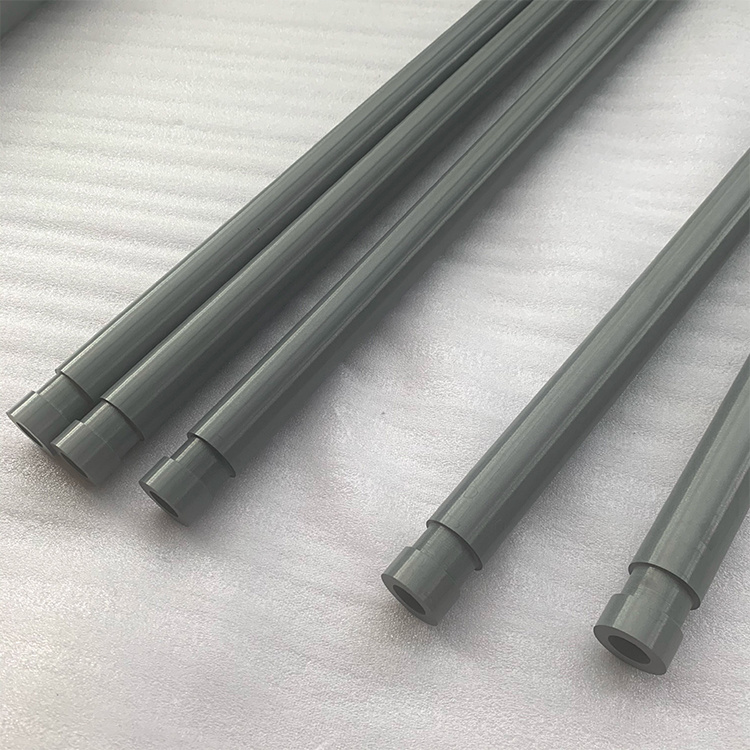

SINTYRON Nitride Bonded Silicon Carbide Rising Tube

Nitride-bonded silicon carbide rising tubes are critical for high-performance industrial applications where extreme temperatures, thermal cycling, and corrosion resistance are required. Their durability and efficiency make them a preferred choice in demanding environments.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

Nitride Bonded Silicon Carbide Rising Tube Description

1. Composition & Structure

Silicon Carbide (SiC): Provides excellent thermal conductivity, high strength, and resistance to thermal shock and corrosion.

Nitride Bonding (Si₃N₄ or other nitride phases): Enhances mechanical properties and oxidation resistance by forming a strong ceramic bond between SiC grains.

2. Key Properties

High-Temperature Resistance: Can withstand temperatures up to 1500°C (2732°F) or higher.

Thermal Shock Resistance: Low thermal expansion and high thermal conductivity prevent cracking under rapid temperature changes.

Corrosion Resistance: Resists acids, alkalis, and molten metals/slag.

Mechanical Strength: High hardness and wear resistance.

Oxidation Resistance: Nitride bonding improves stability in oxidizing atmospheres.

Applications

Metal Melting & Casting: Used as riser tubes in foundries to feed molten metal into molds, reducing shrinkage defects.

Glass Industry: Employed in glass tank furnaces for handling molten glass.

Chemical Processing: Ideal for reactors, heat exchangers, and piping in corrosive environments.

Heat Treatment Furnaces: Used for radiant tubes and protective sheaths.

Advantages Over Other Materials

Outperforms traditional refractory materials like alumina or zirconia in thermal shock resistance.

Longer service life than oxide-bonded SiC due to nitride bonding’s stability.

More cost-effective than pure reaction-bonded silicon carbide (RBSC) for some applications.

Why us?

* Professional manufacturer since 1997.

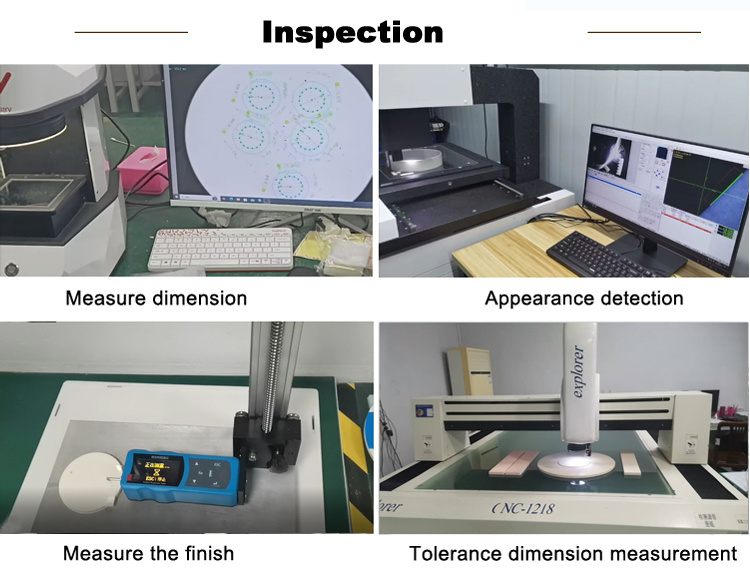

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea,

we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.