PRODUCT CENTER

XING TAL LONG

Recommended Products

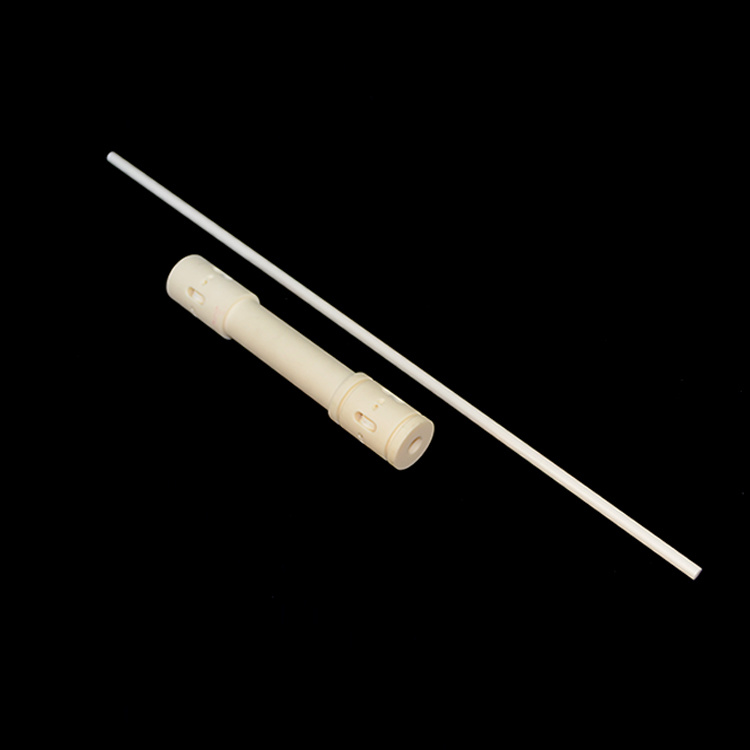

Sintyron Custom Alumina Oxide Bushing for LCD Panel Semiconductor Processing

High-purity alumina ceramic bushings for precision insulation and thermal stability in LCD/semiconductor manufacturing

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

Product Overview

Our precision-engineered Alumina Oxide (Al₂O₃) Ceramic Bushings are designed for demanding

applications in LCD panel manufacturing and semiconductor processing. With exceptional

thermal stability, electrical insulation, and wear resistance, these bushings ensure reliability in

high-temperature and corrosive environments.

Key Advantages:

99%+ Al₂O₃ Purity – Superior dielectric strength & chemical resistance

Operating Temp: -50°C to 1600°C – Ideal for semiconductor thermal cycles

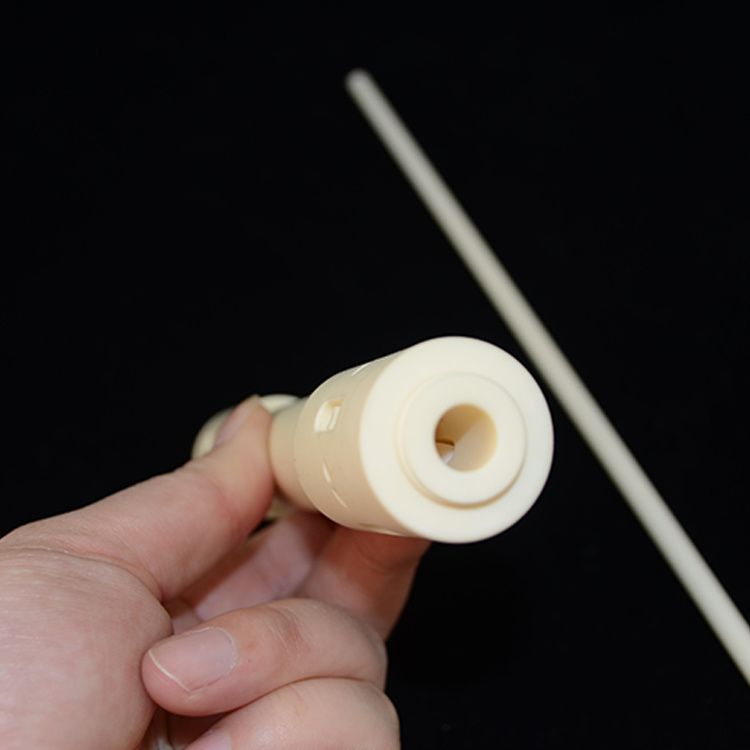

Custom Dimensions – Tailored inner/outer diameters & lengths (OEM support)

Smooth Surface Finish – Ra ≤0.2μm, critical for LCD panel alignment

Product description

Technical Specifications

| Parameter | Specification |

| Material | 99% Alumina Oxide (Al₂O₃) |

| Density | ≥3.9 g/cm³ |

| Hardness | HV 1500-1600 |

| Dielectric Strength | 15-20 kV/mm |

| Thermal Conductivity | 30 W/m·K (25°C) |

| CTE | 8.0×10⁻⁶/°C (20-500°C) |

| Surface Finish | Polished/Ground (Customizable) |

Key Properties of Alumina Ceramic for End Effectors

High Hardness: Alumina ceramics are extremely hard, making them resistant to wear and abrasion.

Thermal Stability: They can withstand high temperatures without degrading, making them suitable for high-temperature processes.

Chemical Resistance: Alumina is inert and resistant to most chemicals, acids, and alkalis.

Electrical Insulation: Alumina ceramics are excellent electrical insulators, making them ideal for applications involving electrical components.

Low Density: Alumina is lightweight compared to metals, reducing the overall weight of the robotic system.

Smooth Surface Finish: The material can be polished to a very smooth finish, reducing friction and improving performance.

| Composition | AL95 | AL99 |

| Color | White | Ivory |

| Density (g/cm3 ) | 3.72 | 3.85 |

| Thermal conductivity (W/m. K) | 22.3 | 32 Kpsi |

| Thermal Expansion (x10-6 /℃) | 8 | 8.2 |

| Dielectric Constant (at 1MHZ) | 9.5 | 9.8 |

| Loss Tangent (x10-4 at 1MHZ) | 3 | 2 |

| Volume Resistivity (ohm-m) | >1014 | >1014 |

| Flexural Strength (N/mm2 ) | 350 | 500 |

Applications of Custom Alumina Ceramic End Effectors

Semiconductor Manufacturing:

Handling silicon wafers, chips, and other delicate components.

Resisting electrostatic discharge (ESD) and contamination.

High-Temperature Environments:

Used in furnaces, kilns, or welding applications where heat resistance is critical.

Abrasive Material Handling:

Gripping or manipulating abrasive materials like glass, ceramics, or metals.

Medical and Pharmaceutical Industries:

Handling sensitive materials in sterile environments due to alumina's biocompatibility and chemical resistance.

Automation and Robotics:

Precision gripping, lifting, or positioning of components in manufacturing processes.

Electronics Assembly:

Handling small, delicate electronic components without causing damage.

FAQ:

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea,

we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.