PRODUCT CENTER

XING TAL LONG

Recommended Products

SINTYRON alumina zirconia trace filling ceramic pump

Alumina-zirconia trace-filled ceramic pumps are ideal for extreme environments where traditional metal pumps fail. Their combination of hardness, toughness, and chemical inertness makes them invaluable in industries requiring durability and reliability.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

SINTYRON alumina zirconia trace filling ceramic pump

Alumina-zirconia trace filling ceramic pumps are specialized components used in demanding

applications where high wear resistance, corrosion resistance, and mechanical strength are required.

These pumps leverage the superior properties of alumina (Al₂O₃) and zirconia (ZrO₂) ceramics,

often with trace additives to enhance performance.

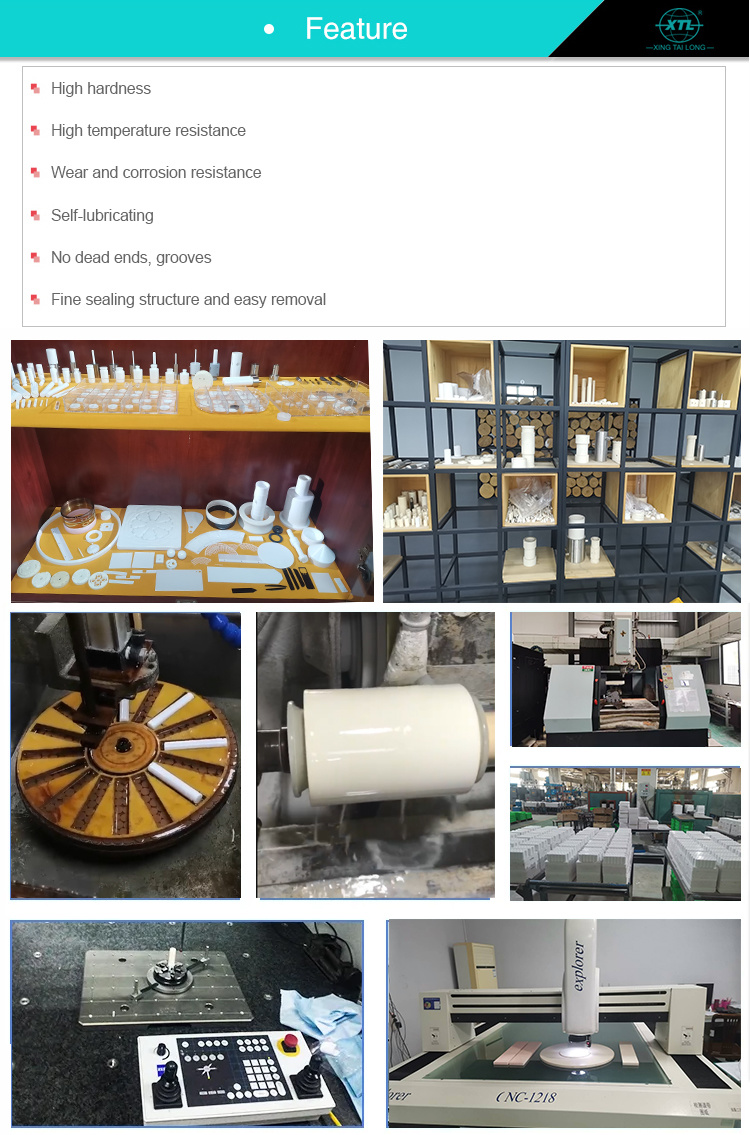

Key Features:

1: Material Composition:

Alumina (Al₂O₃): Provides excellent hardness, wear resistance, and chemical stability.

Zirconia (ZrO₂): Offers high fracture toughness, thermal shock resistance, and strength.

Trace Fillers: Small amounts of other ceramics (e.g., silicon carbide, titanium oxide) may be added to

improve specific properties like thermal conductivity or abrasion resistance.

2:Applications:

Chemical Processing: Handling corrosive fluids, acids, and alkalis.

Mining & Slurry Transport: Resistant to abrasive particles in slurry pumps.

Oil & Gas: Used in harsh environments with high wear and chemical exposure.

Food & Pharmaceutical: Where contamination-free pumping is critical.

High-Temperature Fluids: Suitable for molten metals or hot water applications.

3:Advantages:

Extreme Wear Resistance: Outlasts metal pumps in abrasive conditions.

Corrosion Resistance: Inert to most acids, alkalis, and solvents.

High-Temperature Stability: Can operate in environments exceeding 1000°C (depending on composition).

Lightweight: Lower inertia compared to metal alternatives.

Non-Reactive: Ideal for ultra-pure or sensitive fluids.

| Property | Benefit |

| Hardness (9 Mohs) | Resists abrasion from slurries & particulates |

| Chemical inertness | Withstands acids, alkalis, solvents |

| High compressive strength | Handles extreme pressures (>500 MPa) |

| Low thermal expansion | Stable in high-temperature environments |

| Smooth surface finish (Ra <0.2µm) | Reduces friction & improves sealing |

| Non-magnetic & electrically insulating | Suitable for sensitive applications |

FAQ

Why us?

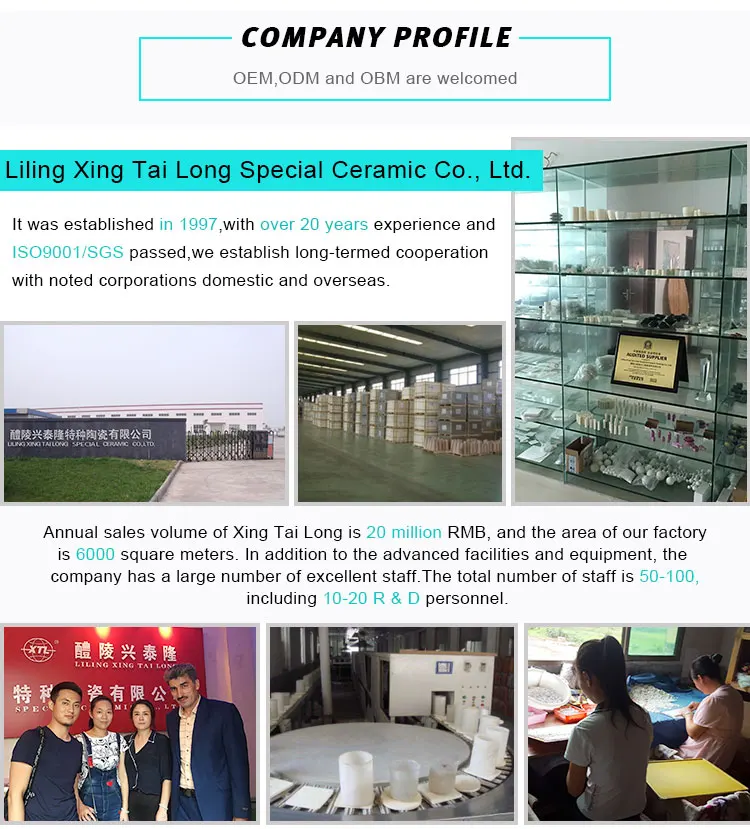

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing,

just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.