PRODUCT CENTER

XING TAL LONG

Recommended Products

SINTYRON 997 99 al2o3 high purity alumina ceramic vacuum tube

Alumina (Al₂O₃) ceramic vacuum tubes are critical components in high-temperature, high-vacuum, and electrically insulating environments.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

SINTYRON 997 99 al2o3 high purity alumina ceramic vacuum tube

Alumina vacuum ceramic tubes are high-performance ceramic material products, widely used in high vacuum, high temperature, insulating or corrosive environments

Product description:

-

Material: 99% Al₂O₃ (or 95% for cost-sensitive uses)

-

Porosity: Adjustable (20%–50%)

-

Pore Size: 1μm–100μm (customizable)

-

Max. Temperature: 1600°C

-

Diameter/Length: OEM support

We can do OEM and OBM according to your drawing and requires:

Key Features:

Material: Made from high-purity alumina (typically 95% to 99.8% Al₂O₃), offering:

High thermal stability

Excellent electrical insulation

Superior mechanical strength

Resistance to corrosion and wear

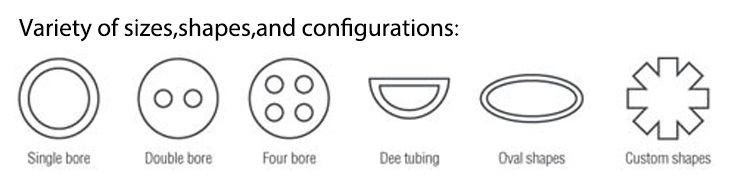

Oval Shape: The oval cross-section provides a larger surface area compared to round tubes, which can

be beneficial in applications like heat transfer or fluid flow.

Double Bore Design: The two parallel bores allow for the simultaneous passage of different materials,

gases, or fluids, making it ideal for applications requiring separation or controlled flow.

Dimensions: Customizable in terms of length, bore diameter, wall thickness, and oval dimensions to suit

specific requirements.

Application field:

Vacuum system: As a vacuum chamber, observation window, electrode feedthrough device (such as semiconductor equipment, particle accelerators).

Electronic devices: high-voltage insulating bushings, vacuum capacitors, vacuum switch tube shells.

Energy field: Sodium-sulfur batteries, sealed isolation tubes for thermoelectric conversion devices.

Scientific research equipment: high-temperature furnace tubes, laser tubes, mass spectrometer components.

Industrial field: Corrosive gas conveying pipes, high-temperature sensor protective sleeves.

| Composition | AL95 | AL99 |

| AL2O3 Content | 97% | 99.80% |

| Color | White | Ivory |

| Tensile | 30 Kpsi | 32 Kpsi |

| Flexural | 55 Kpsi | 60 Kpsi |

| Compressive | 300 Kpsi | 330 Kpsi |

| Density | 3.7 g/cc | 3.92 g/cc |

| Hardness | 13.8 HV, Gpa | 18 HV, Gpa |

| Thermal Conductivity | 25 W/(m K) | 32 W/(m K) |

| C.O.T.E. | 77 In / In°C (x10^7) | 78 In / In°C (x10^7) |

| Working Temperature | 1500 °C | 1750 °C |

| Dielectric Constant | 9.5 | 9.8 |

| Volume Resistivity | >10^14 Ohm-cm | >10^15 Ohm-cm |

| Dielectric Strength | 16 KV/mm | 20 KV/mm |

Advantages:

-

High thermal shock resistance

-

Low thermal conductivity

-

Chemically inert

-

Long service life in harsh environments

Customization:

These tubes can be tailored to meet specific requirements, such as:

-

Different alumina purity levels

-

Surface finishes (e.g., polished, glazed)

-

Precision tolerances for bore size and ovality

If you need more details about specific properties, applications, or suppliers,

feel free to ask!

Why Choose Our Porous Alumina Tubes?

Precision Engineered – Consistent pore distribution for reliable performance.

Lab-Tested Durability – Rigorous QC ensures longevity in extreme conditions.

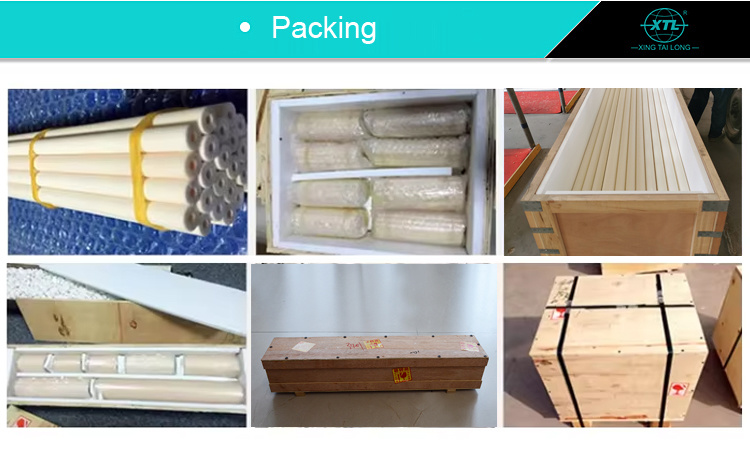

Global Shipping – Fast delivery with OEM/ODM services.

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t

have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.