PRODUCT CENTER

XING TAL LONG

Recommended Products

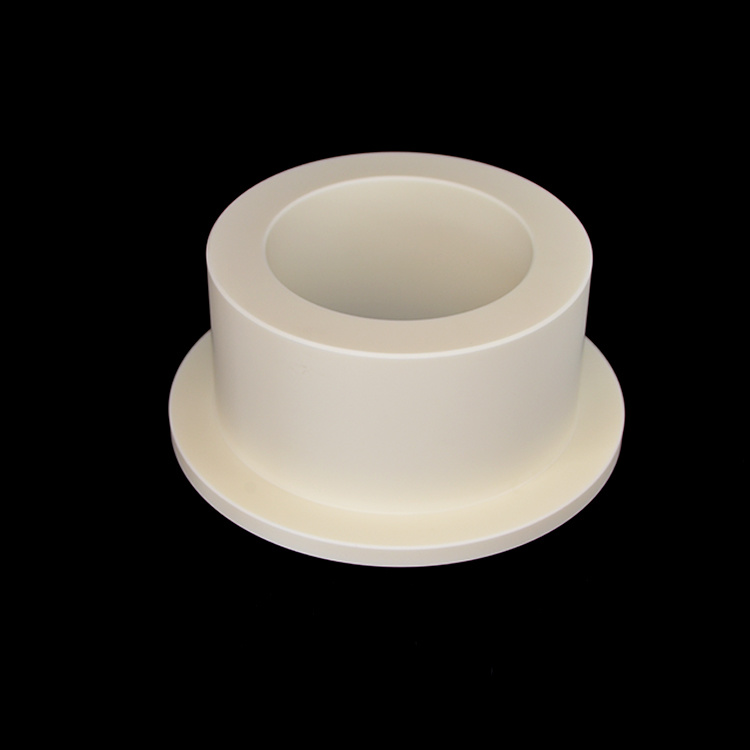

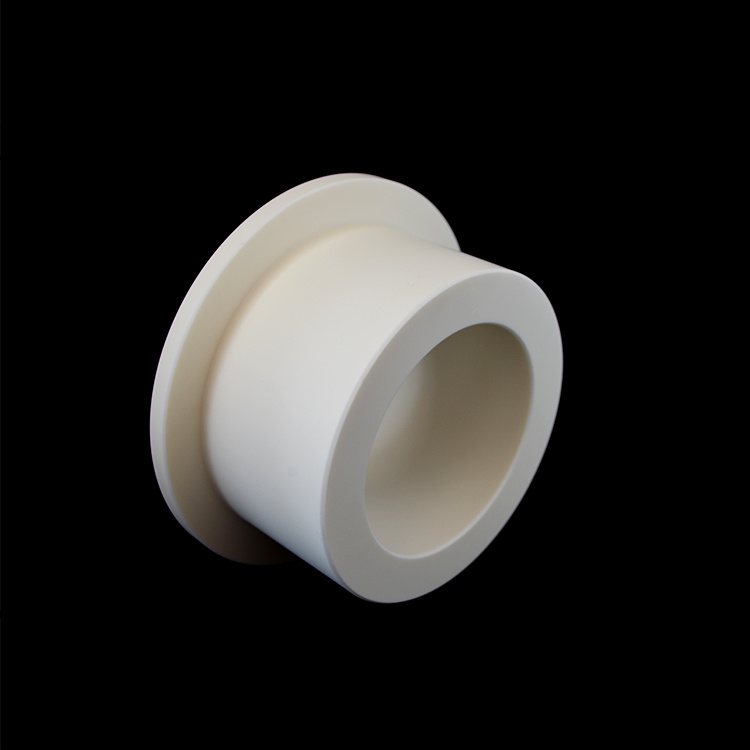

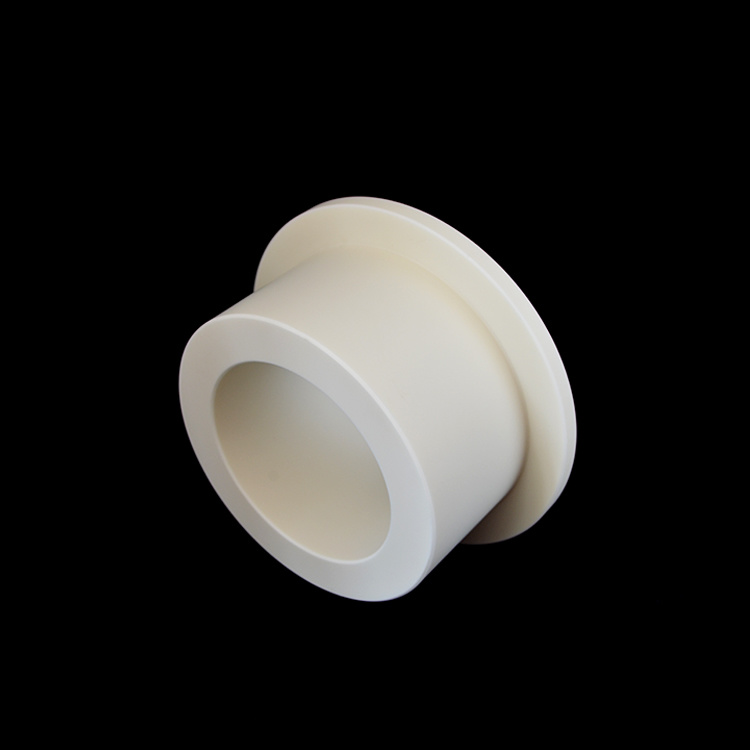

SINTYRON Wear Resistant 99% alumina ceramic insulating sleeve insulator bush

Alumina ceramic parts are special ceramic products made with alumina (Al₂O₃) as the main material, featuring high mechanical strength, high-temperature resistance, and corrosion resistance. The production process includes hot-pressing injection molding, fully automatic press forming, and high-temperature sintering, among others. Their application fields cover multiple industries such as electronics and electrical appliances, mechanical and textile, chemical equipment, and automotive industry.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

SINTYRON Wear Resistant 99% alumina ceramic insulating sleeve insulator bush

Product description:

Ceramic bushing have the characteristics of high hardness and wear resistance, low corrosion level, high temperature resistance,

corrosion resistance and biological inertness.Because of its superior performance, alumina ceramics have become more and more

widely used in modern society to meet the needs of daily use and special performance.

Alumina ceramic bush Information:

| Product | Alumina ceramic bush |

| Material | Al2O3 |

| Purity | 95%-99% |

| Color | White/Nylon yellow |

| Shape | Arc/Square/Rectangle/Cylinder/Boat |

| Capacity | 1-2000 ml |

| Density | 3.98 g/cm3 |

| Melting Point | 2020℃ |

| Max. Working Temperature | 1800 ℃or 3180 F |

Performance parameters:

| Test item | alumina | |||

| index | unit | AL997 | AL99 | AL95 |

| Principal component content | N/A | 99.70% | 99% | 95% |

| Color | N/A | ivory white | ivory yellow | White |

| Gas permeability | N/A | airtight | airtight | airtight |

| density | g/cm3 | 3.9 | 3.8 | 3.7 |

| hardness | Moh's hardness | 9 | 9 | 8.8 |

| Water Absorption | N/A | ≤0.2 | ≤0.2 | ≤0.2 |

| Bending strength (20°C) | Mpa | 375 | 340 | 304 |

| Compressive Strength (20°C) | Mpa | 2300 | 2210 | 1910 |

| Coefficient of thermal expansion (25°C to 800° C) | 10X6/° C | 7.6 | 7.6 | 7.6 |

| Insulation strength (5mm thickness) | AC-kv/mm | 10 | 10 | 10 |

| Dielectric loss 25°C lMHz | N/A | 0.0001 | 0.0006 | 0.0004 |

| dielectric constant 25°C MHz | N/A | 9.8 | 9.5 | 9.2 |

| Volume resistivity (20°C) (300°C) (500 °C) | Ω.cm3 | >1014 | >1014 | >1014 |

| 2X1012 | 4X10" | 2X10" | ||

| N/A | N/A | N/A | ||

| Long-term service temperature | ℃ | 1700 | 1600 | 1400 |

| Thermal conductivity (25° C) | W/m/K | 35 | 34 | 20 |

Properties of Alumina Ceramic Bush

-

Material Composition: Typically made from 92%–99.8% alumina (Al₂O₃), offering high purity and performance .

-

Mechanical Properties:

-

High hardness (Mohs 9) and wear resistance .

-

Low gas permeability and water absorption (<0.08%) .

-

High thermal conductivity (18–40 W/m·K) and electrical insulation .

-

High-temperature resistance (up to 1650–1750°C) .

-

-

Customizability: Available in various sizes, colors (white, black, ivory), and shapes, with options for CNC machining .

Applications of Alumina Ceramic Bush:

1.Industrial machinery Textile machinery (knitting needles, yarn guiding components) Wear-resistant liners, bearings, sealing rings.

2.Electronic power High-voltage insulators, integrated circuit boards, spark plug insulators.

3.Chemical Engineering and Environmental Protection.

4.Corrosion-resistant pumps and valves, catalyst carriers, and filter membranes.

5.Aerospace High-temperature heat insulation tiles, missile fairing (heat-resistant shock)

Manufacturers and Suppliers

-

AdValueTech: Offers alumina plates in various dimensions and thicknesses, with customization options available.

-

CERADIR: Provides 99.7% alumina plates with high reliability and thermal stability, suitable for industrial and

electronic applications. -

MICROPLAN ITALIA: Manufactures precision alumina surface plates with high flatness tolerances, available in custom

sizes and configurations. -

AGILEEN: Supplies high-quality alumina plates with a wide range of sizes and dimensions, suitable for various

industrial applications.

Customization and Quality Assurance

-

Customization: Many manufacturers offer alumina plates tailored to specific dimensions, shapes, and performance requirements

based on customer drawings or samples. -

Quality Control: Manufacturers adhere to strict quality control processes, including ISO certifications, to ensure the plates meet

high standards of durability and performance

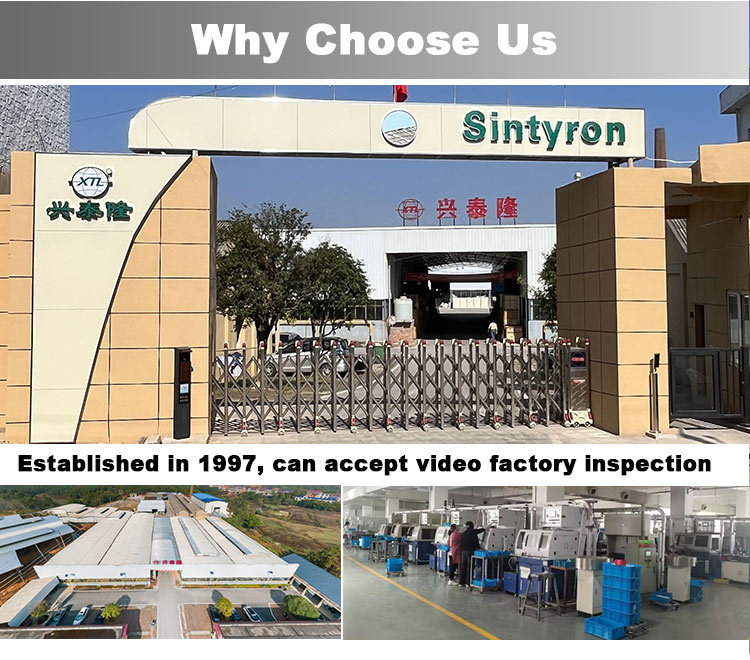

Company Information:

FAQ:

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea,

we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.