PRODUCT CENTER

XING TAL LONG

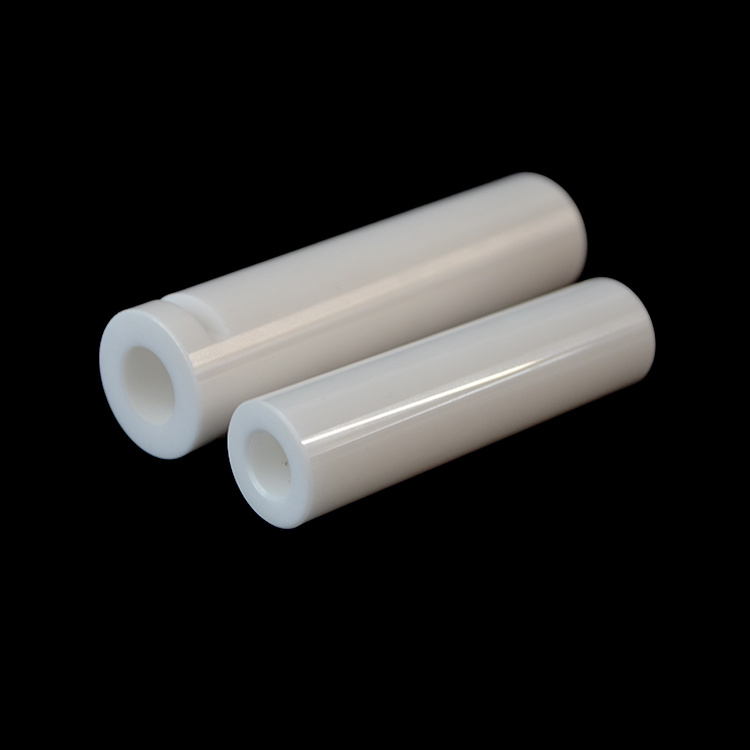

SINTYRON Zirconia Ceramic Biomedical Ceramic Plunger Pump

Zirconia ceramic filling pumps are precision fluid handling devices that use yttria-stabilized zirconia (YSZ) as the core material for critical components like plungers, cylinders, and valves. These pumps are engineered for applications demanding ultra-high purity, exceptional wear resistance, and corrosion immunity, such as in pharmaceuticals, food and beverage, cosmetics, and chemical industries

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

SINTYRON Zirconia Ceramic Biomedical Ceramic Plunger Pump

Zirconia ceramic filling pumps represent the pinnacle of precision fluid handling technology, combining unmatched wear resistance,

chemical inertness, and biocompatibility. They are indispensable in industries where purity, accuracy, and reliability are non-negotiable.

While their upfront cost is higher, their extended service life and minimal maintenance needs make them a cost-effective solution for critical applications

Key Properties and Advantages

1.Exceptional Wear Resistance & Hardness

Zirconia's high hardness (≥HRA 88, Vickers ~1200-1300 HV) and low friction coefficient (~0.02) minimize abrasion between moving parts

(e.g., plunger and sleeve), ensuring longevity even with abrasive fluids.

This reduces particle generation, critical for contamination-sensitive applications like vaccine packaging or semiconductor chemical handling.

2.Chemical Inertness & Corrosion Resistance

Resists strong acids, alkalis, solvents, and oxidizing agents (e.g., H₂O₂), making it ideal for aggressive media.

Unlike metals, it prevents ion leaching (e.g., iron ions <0.1 ppb), crucial for battery electrolyte dispensing or pharmaceutical formulations.

3.High Fracture Toughness

Zirconia’s transformation toughening mechanism provides mechanical robustness, reducing chipping or cracking risks during operation or handling.

4.Ultra-Smooth Surface & Biocompatibility

Polished to surface roughness Ra ≤0.1 μm, preventing fluid adhesion and enabling easy sterilization (e.g., steam sterilization at ≥140°C).

Complies with FDA, ROHS, and GMP standards for medical and food contact applications

Zirconia ceramic filling pumps of Applications

1.Chemical Industry

In chemical production, zirconia ceramic plunger pumps can stably deliver strong acids like sulfuric acid and hydrochloric acid, as well as

strong alkaline solutions like sodium hydroxide. Their corrosion resistance ensures long-term operation in corrosive environments.

2.Food and Beverage Industry

Ceramic materials are non-toxic and harmless, and do not react chemically with food. They are commonly used in beverage filling processes,

enabling precise flow control and ensuring product consistency.

3.New Energy Industry

In lithium battery production, zirconia ceramic plunger pumps achieve submicron precision control of electrolyte delivery, significantly extending

equipment life (for example, from one year to over 10 years) and reducing maintenance costs by 80%.

4.Medical Industry

In the pharmaceutical industry, ceramic plunger pumps are FDA-certified, preventing metal ion contamination of drug solutions. They are commonly

used for filling and metering liquid preparations such as aqueous injections and lyophilized powder injections.

5.Aerospace

Their lightweight and robust properties make them an ideal material for high-temperature aerospace components, improving equipment performance

and fuel efficiency.

| Y-FSZ Ceramic Properties | ||

| Chemical content | ZrO2 | 86 wt% |

| Y2O3 | 14 wt% | |

| Physical Properties | Melting point | ≥2500℃ |

| Max. operating temperature | 2200℃ | |

| Color | White | |

| Density | 5.8g/cm3 | |

| Mechanical properties | Flexural strength | 200MPa |

| Young’s module | 200GPa | |

| Hardness(HRA) | 86 | |

| Thermal properties | Thermal expansion coefficient(20℃) | 8-10X10-6 |

| Thermal conductivity | 1-2W/mk | |

| Electrical properties | Dielectric constant(1MHz25℃) | 12 |

| Electrical resistivity(25℃) | 109 | |

Advantages and Limitations

Advantages:

Excellent overall mechanical properties (strength, toughness, and hardness).

Excellent chemical and high-temperature resistance.

Good thermal and electrical insulation.

Good biocompatibility.

Limitations:

Higher cost: Both the raw material and sintering process are more expensive than common ceramics like alumina.

Brittleness: Despite its high toughness among ceramics, it is still inherently brittle compared to metals and must be protected from severe impact and stress concentration.

Weight: High density (approximately 6 g/cm³), heavier than both alumina and silicon carbide.

FAQ

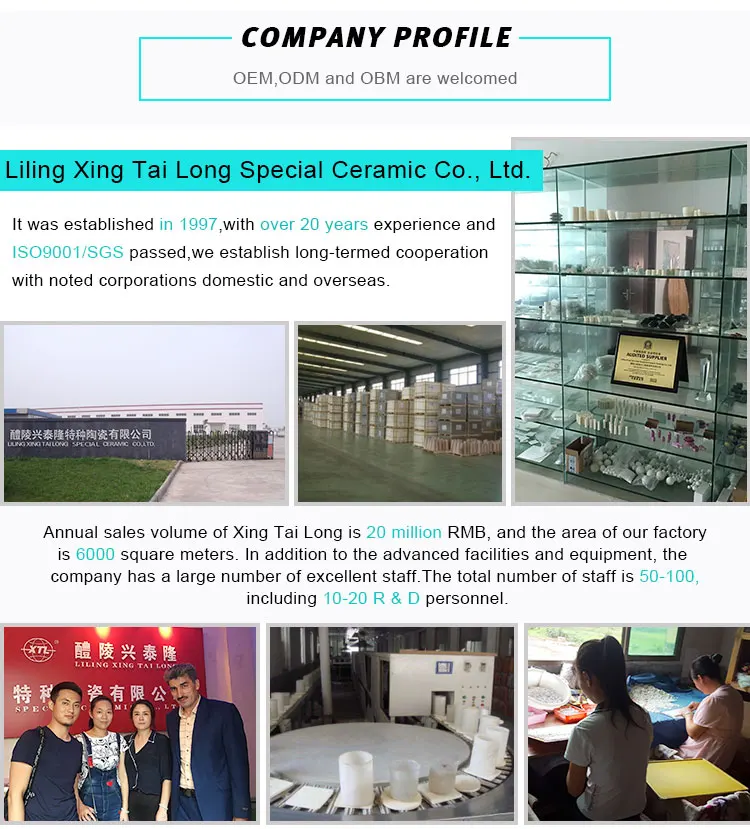

Why us?

* Professional manufacturer since 1997.

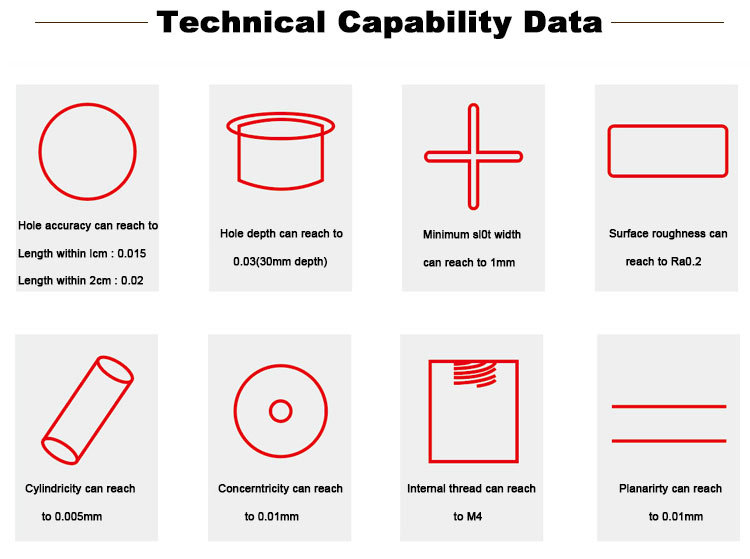

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.