PRODUCT CENTER

XING TAL LONG

Recommended Products

SINTYRON 99% alumina ceramic parts Pharmaceutical filling pump

alumina ceramic plunger pump is a premium, highly durable solution for pumping abrasive and corrosive fluids, offering unmatched wear life and reliability in challenging industrial environments.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

SINTYRON 99% alumina ceramic parts Pharmaceutical filling pump

Medical equipment zirconia ceramic piston plunger is a type of plunger used in medical

devices, such as syringes and pumps, that is made from zirconia ceramic material. This

material is known for its high strength, hardness, and wear resistance, making it ideal for

applications where durability and precision are critical.

Compared to a regular zirconia plunger, the medical equipment zirconia ceramic piston

plunger has several key differences that make it suitable for medical use. Firstly, the medical

equipment plunger is specifically designed for medical applications, with tight tolerances

and precise dimensions to ensure smooth operation and accurate dosage delivery. This level

of precision is crucial in medical devices where even the smallest deviation can have serious

consequences for the patient.

Secondly, the medical equipment plunger is often coated with a biocompatible material, such

as silicone or PTFE, to prevent any potential interaction with the medication being dispensed.

This coating helps to ensure the purity of the medication and prevents any contamination that

could compromise the patient's health.

Additionally, the medical equipment zirconia ceramic piston plunger may have a specialized

design, such as a double seal or leak-proof construction, to prevent any leakage or loss of

medication during use. This feature is essential in medical devices where accurate dosage delivery

is critical and any loss of medication could have serious implications for the patient.

Furthermore, the medical equipment plunger may undergo additional testing and certification to

ensure its safety and reliability in medical applications. This can include biocompatibility testing,

sterility testing, and validation of performance under various conditions to ensure that the plunger

meets the stringent requirements of the medical industry.

| Y-FSZ Ceramic Properties | ||

| Chemical content | ZrO2 | 86 wt% |

| Y2O3 | 14 wt% | |

| Physical Properties | Melting point | ≥2500℃ |

| Max. operating temperature | 2200℃ | |

| Color | White | |

| Density | 5.8g/cm3 | |

| Mechanical properties | Flexural strength | 200MPa |

| Young’s module | 200GPa | |

| Hardness(HRA) | 86 | |

| Thermal properties | Thermal expansion coefficient(20℃) | 8-10X10-6 |

| Thermal conductivity | 1-2W/mk | |

| Electrical properties | Dielectric constant(1MHz25℃) | 12 |

| Electrical resistivity(25℃) | 109 | |

alumina ceramic plunger pump is a type of positive displacement pump designed for handling demanding, abrasive, and often corrosive fluids.

Its defining characteristic is the use of components—primarily the plunger, sleeve, and valve parts—manufactured from high-purity aluminum

oxide (Al₂O₃) ceramic.

Properties of alumina ceramic:

-

Extreme Hardness & Wear Resistance: Alumina ceramic is second only to diamonds in hardness. This makes it exceptionally resistant to

abrasion from suspended solid particles in fluids (e.g., slurries, paints, pigments). This drastically reduces wear and extends service life

compared to metal pumps. -

Excellent Corrosion Resistance: It is highly inert and resistant to a wide range of corrosive chemicals, acids, and solvents, making it

unsuitable for applications where metals would rapidly degrade. -

High Compressive Strength: The material can withstand the very high pressures generated within the pump chamber without deforming.

-

Smooth Surface Finish: Ceramic components can be polished to an extremely fine, mirror-like surface. This reduces friction, minimizes

fluid adhesion, and improves cleaning efficiency. -

Thermal Stability: Alumina ceramic maintains its properties at high temperatures, suitable for pumping hot fluids.

Alumina Ceramic Plunger Pump of Application:

These pumps are essential in industries where longevity and reliability with difficult fluids are critical:

-

Surface Treatment: Pumping abrasive abrasive abrasives, acidic/alkaline chemicals in electroplating, anodizing, and phosphating lines.

-

Ceramic & Sanitary Industry: Transferring ceramic glazes, slurries, and enamels.

-

Chemical Processing: Metering and transferring corrosive chemicals, solvents, and aggressive media.

-

Mining & Mineral Processing: Handling abrasive mineral slurries and tailings.

-

Pharmaceutical & Food: Where high purity, cleanliness, and resistance to cleaning agents (CIP - Clean-in-Place) are required.

The operating principle is similar to a standard reciprocating plunger pump:

Suction Stroke: The ceramic plunger retracts, creating a vacuum in the pump chamber. This causes the inlet valve to open, drawing

fluid into the chamber.

Discharge Stroke: The plunger moves forward, pressurizing the fluid in the chamber. The inlet valve closes, and the discharge valve

opens, forcing the fluid out into the delivery system.This reciprocating motion is typically driven by an electric motor and a crankshaft

or cam assembly.

FAQ

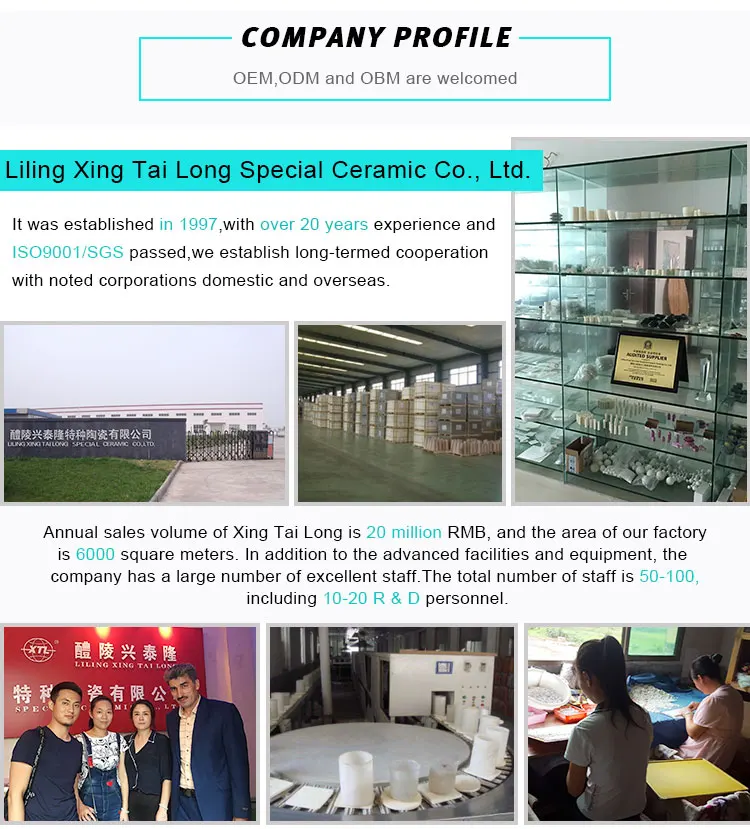

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing,

just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.