PRODUCT CENTER

XING TAL LONG

Recommended Products

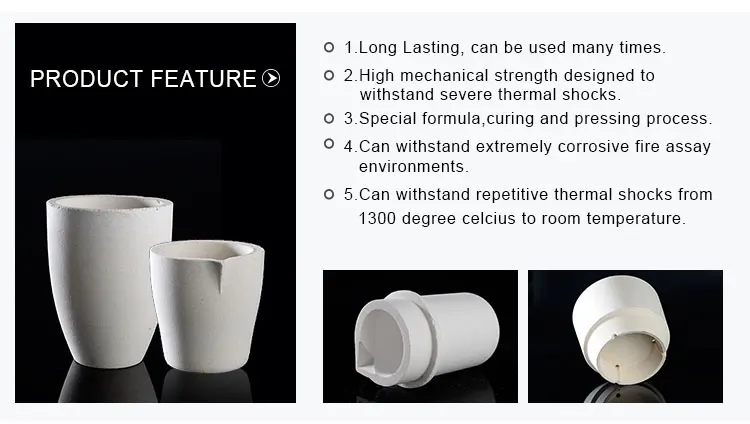

Laboratory Porcelain Fire assay crucible 750ml

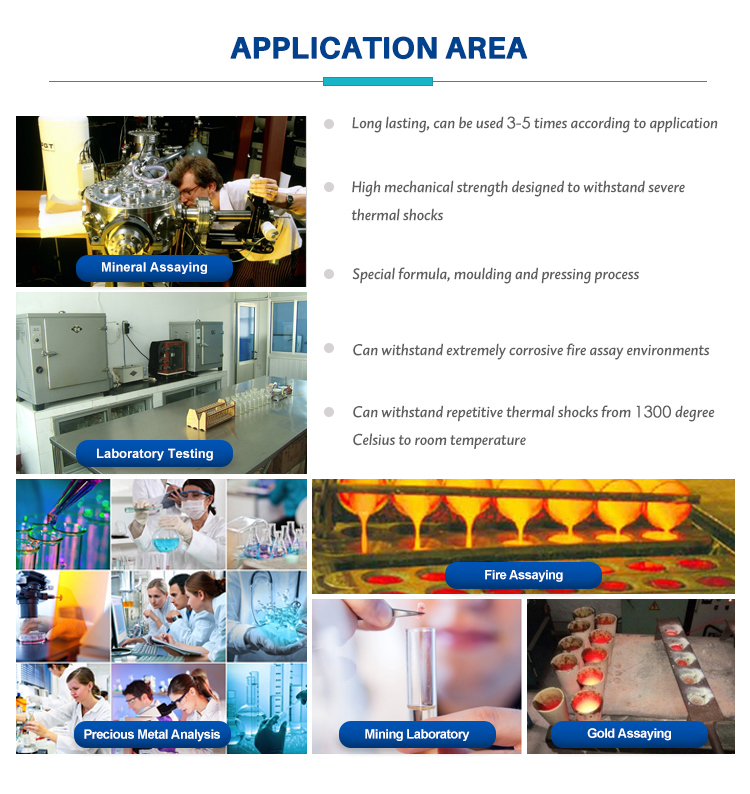

The crucible made of fire assay gold is commonly used in industries that require precise measurements of precious metals, such as jewelry making, metal refining, and mining. Its high melting point and thermal conductivity make it ideal for melting and testing metals at extreme temperatures. The crucible's durable material and resistance to corrosion also make it suitable for use in laboratories and research facilities where accurate analysis of metal composition is essential. Overall, the fire assay gold crucible is an essential tool for industries that rely on the accurate assessment of metal purity and composition, making it a valuable asset for goldsmiths, metallurgists, and mining companies.

Email: sintyron@xtlceramic.com

Inquiry NowProducts Center

Laboratory Porcelain Fire assay crucible

Before using a fire assay crucible, there are several preparations that need to be made to ensure

accurate and reliable results.

1. Pre-heating the crucible: To prevent thermal shock and cracking, the crucible should be pre-heated

slowly and evenly before use. This can be done in a muffle furnace or an open flame, depending on the

material of the crucible.

2. Weighing the sample: The sample to be assayed should be accurately weighed before placing it in the

crucible. This is crucial for calculating the final results of the assay.

3. Adding flux: Depending on the type of assay being performed, a flux may need to be added to the sample

in the crucible. The flux helps to fuse the sample and facilitate the separation of the precious metals.

4. Filling the crucible: Carefully place the sample and any necessary flux into the pre-heated crucible, making

sure not to spill or contaminate the contents.

5. Heating the crucible: Once the crucible is filled, it should be heated to the required temperature for the assay.

This can be done in a muffle furnace or using a torch, depending on the specific requirements of the assay.

6. Cooling the crucible: After the assay is complete, allow the crucible to cool slowly to avoid thermal shock and

cracking. Once cooled, the contents can be removed for further processing and analysis.

By following these steps and properly preparing the fire assay crucible, accurate and reliable results can be obtained

in the assay process.

|

Item: |

Fire assay crucible |

|

Process Type: |

Rolling molding |

|

Material: |

SiO2 + Al2O3 |

|

Tolerance: |

+-2mm |

|

Facility: |

Automatic molding equipment |

|

Certificates: |

ISO 9001 SGS |

|

Shipping: |

Many stocks , delivery time around 5-10days . by sea or by air as customer request |

|

Delivery & Service: |

Timely delivery each time. Provide reliable service and responsible for each customer with each product. Our target is to satisfy every customer with the best service. |

Chemical Composition

|

SiO2 |

54.6% |

|

Al2O3 |

40.31% |

|

Fe2O3 |

1.11% |

|

TiO2 |

0.47% |

|

CaO |

1.28% |

|

MgO |

0.34% |

|

K2O |

0.61% |

|

Na2O |

0.39% |

|

L.O.I(loss on ignition) |

0.21% |

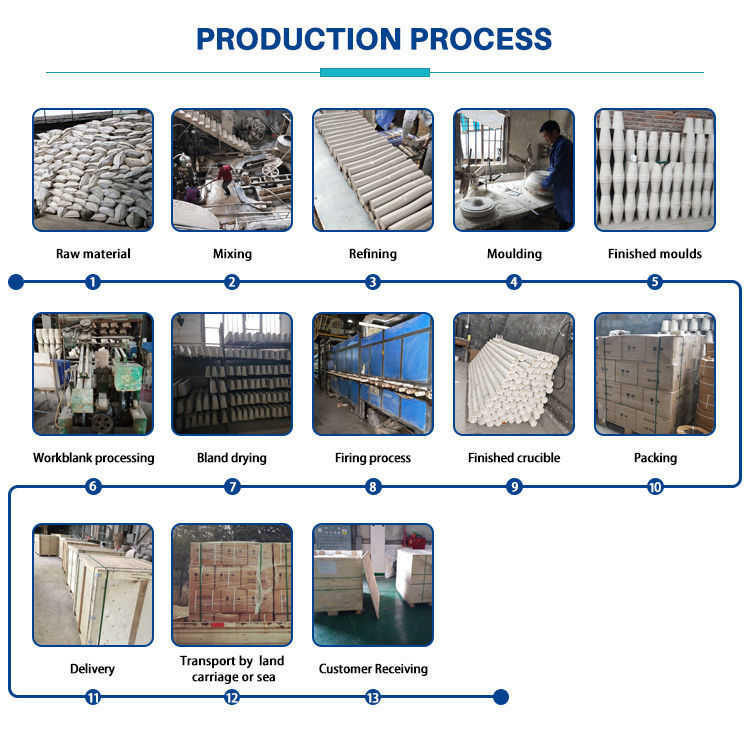

OUR ADVANTAGE:

7000 square meters work shop

Automatic production line

Longer working life

Reasonable price

All prototype products have to go through 4 checks in the whole process:

1. Raw material inspection

2. In processing inspection

3. Final inspection

4. Outgoing inspection