PRODUCT CENTER

XING TAL LONG

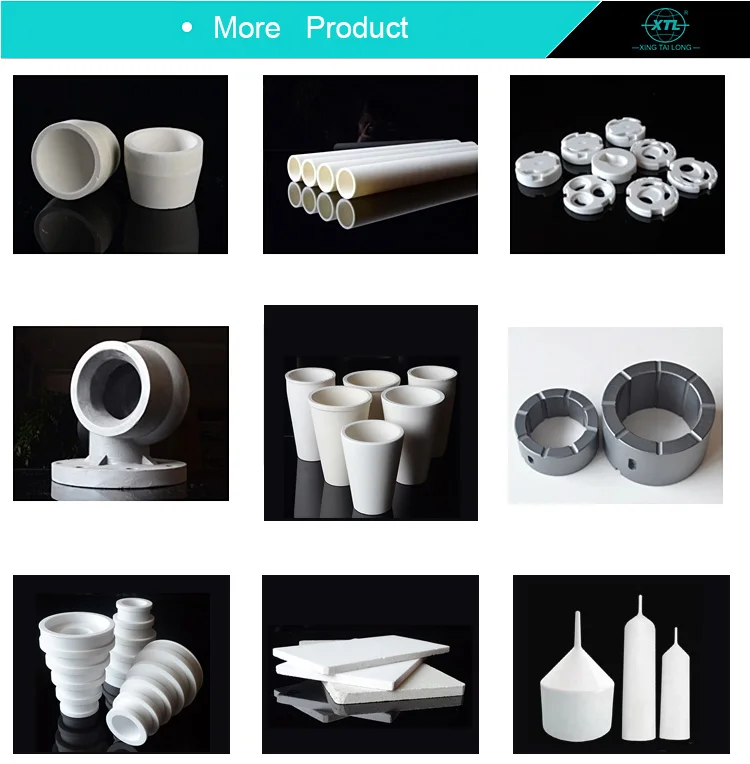

Recommended Products

Factory supply high purity pyrolytic boron nitride PBN crystal production VGF crucible for MBE

Factory supply high purity pyrolytic boron nitride

Contact usProducts Center

Factory supply high purity pyrolytic boron nitride

PBN crystal production VGF crucible for MBE

High purity 99.99% PBN pyrolytic boron nitride ceramic part

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite.

Hot pressed BN is compacted at temperatures up to 2000°C and pressures up to 2000 psi to form a dense, strong engineering material that is easily machined. It is available in standard and custom hot pressed shapes and has several unique characteristics and physical properties which make it valuable for solving tough problems in a wide range of industrial applications.

|

Item |

Unit |

PBN Ceramic Part |

|

|

Apparent Density |

g/cm3 |

2.15-2.19 |

|

|

Gas permeability(He) |

cm3/s |

<1*10-10 |

|

|

Micro hardness(Knoop) |

N/mm2 |

691.88(a-b plane) |

|

|

Tensile strength |

N/mm2 |

153.86(parallel) |

|

|

Bending strength |

N/mm2 |

243.63(parallel) |

197.76(parallel) |

|

Modulus of elasticity |

N/mm2 |

235690 |

|

|

Specific heat capacity |

Cal/g.℃ |

0.371(@ 200℃) |

0.442(@ 900℃) |

|

Thermal conductivity 200℃ |

W/cm.k |

0.6(parallel) |

0.026(perpendicular) |

|

Thermal conductivity 900℃ |

W/cm.k |

0.4370(parallel) |

0.028(perpendicular) |

|

Dielectric Strength(RT) |

KV/mm |

56 |

|

|

Volume Resistivity |

Cm |

3.11*1011 |

|

-LEC, VGF and Bridgman crucibles -Molecular Beam Epitaxy(MBE) crucible

-Semiconductor component -Polycrystalline synthesis boat

-MOCVD heater -PBN infrared window

-PBN coating graphite -Traveling wave tube(TWT) (PBN support rod)

-Microwave application -Electronic component assembling jigs

-PVD coating -Gas burners

-Diffusion source wafers -Electronic components & substrates

-Nozzles for nonferround metals -Crystal Growth

-Heating elements -OLED and MBE effusion cell

1.Why Us?

Professional manufacturer since 1997;

Strict quality control on production process and tolerance;

Free samples available;

Customized production based on your drawing or specification;

On-time delivery and reliable support and service;

Inventory available for quick shipment;

We keep confidentiality of all the drawings and business information between us.

2.Are you a trading company or a manufacturer?

We are a manufaturer.

3.Can you provide the free samples?

Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

4.Do you accept customized production based our specification?

Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

5.What's the delivery time?

7 working days for standard products 30 days for customized products.

6.What is the MOQ?

No limit to the quantity. We can offer the best proposal and solutions according to your condition.

7.What is the payment terms you accept?

T/T,LC,Western Union,moneygram are acceptable.

8.How to deal with the faulty?

Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.