PRODUCT CENTER

XING TAL LONG

Recommended Products

XTL Sintyron customized yttrium stabilized zirconia ceramic grinding ball beads for ball milling

Zirconia balls are a versatile and reliable option for industrial processes that require high performance and durability. With their exceptional properties, they are sure to provide long-lasting and efficient results for various applications.

Contact usProducts Center

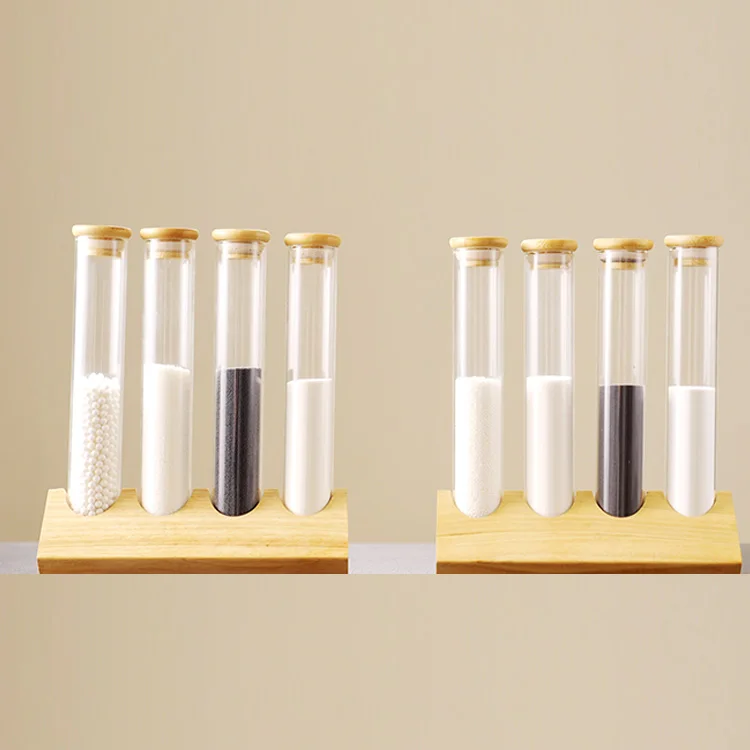

Zirconia ceramic grinding ball beads for ball milling

Zirconia balls are ceramic balls made from zirconium dioxide (ZrO2) material. They are known for their

high strength, hardness, and wear resistance, making them ideal for various industrial applications.

Zirconia balls are commonly used in grinding and milling operations in industries such as mining,

pharmaceuticals, ceramics, and electronics. Their high density and superior grinding efficiency make

them a popular choice for abrasive and high-impact applications.

In addition to their excellent mechanical properties, zirconia balls also exhibit high thermal and chemical

stability, making them suitable for use in harsh environments. They are also inert and non-reactive, making

them safe for use in food processing and medical applications.

1. Brief introduction

We can customize non-standard grinding media, with good wear resistance and high strength, long service life, effectively reducing the use cost.

2. Characteristics and advantages of zirconia beads product materials.

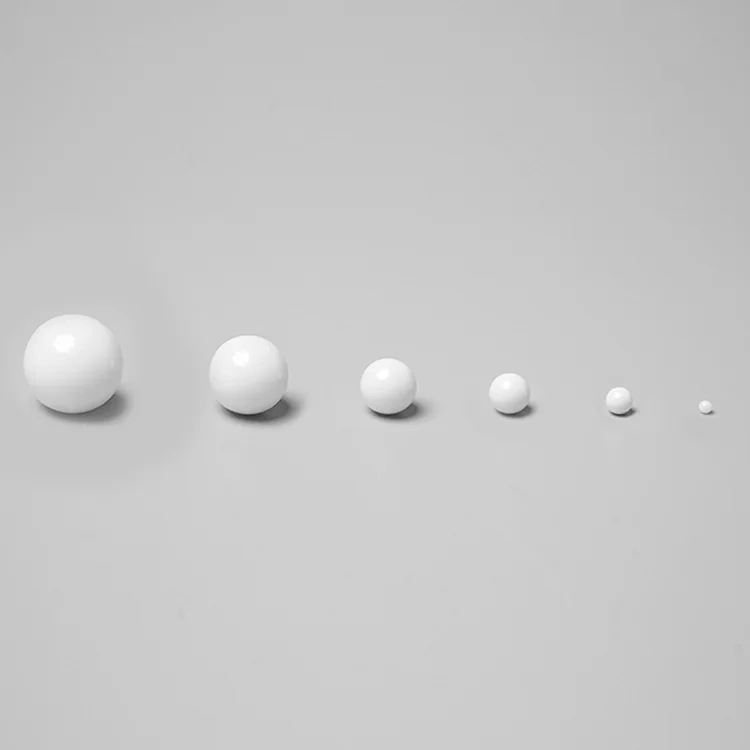

A. Ultra-fine Grain Size: Higher fineness of raw materials, lower wear rate, longer service life.

B. Ultra-high Density: Ultra-dense inner structure, strong impact resistance, no broken beads during use.

C. Uniform Bead Size Distribution: More stable grinding, results more sustainable productions.

D. Smooth Surface: Lower self-wear rate.

3. Product process

• It is made of high-purity Y-TZP raw materials, and high wear resistance.

• Good strength, no broken beads during use.

• It has good self-lubrication and less wear on equipment.

• Good sphericity.

4. Applications

• Commonly used for ultrafine dispersion of various materials, such as new energy, electronic materials, paint coatings, ink graphite, cosmetics, food and medicine, etc.

5. Comprehensive parameters

| Index | ZR95 Nano Zirconia Beads | ZR95 High-purity Zirconia Beads |

| (ZrO2)Zirconia Content | 94.5+0.2(%) | 94.5+0.5 (%) |

| Density | ≥6.03g/cm³ | ≥6.0g/cm³ |

| Bulk Density | 3.75g/cm³ | 3.7g/cm³ |

| Crushing Strength(Φ0.3mm) | ≥10Kgf | ≥9Kgf |

| Sphericity | >0.98Ds/Dl | >0.95Ds/Dl |

| Size tolerance rate | ≈0.5‰ | ≈1‰ |

| Internal Self-wear | <17ppm/h | <30ppm/h |

| Vickers Hardness | ≥1250HV | ≥1230HV |

| Beads Size Range Available | Φ0.05-Φ2.0mm | Φ0.3-Φ5.0mm |

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.