PRODUCT CENTER

XING TAL LONG

Recommended Products

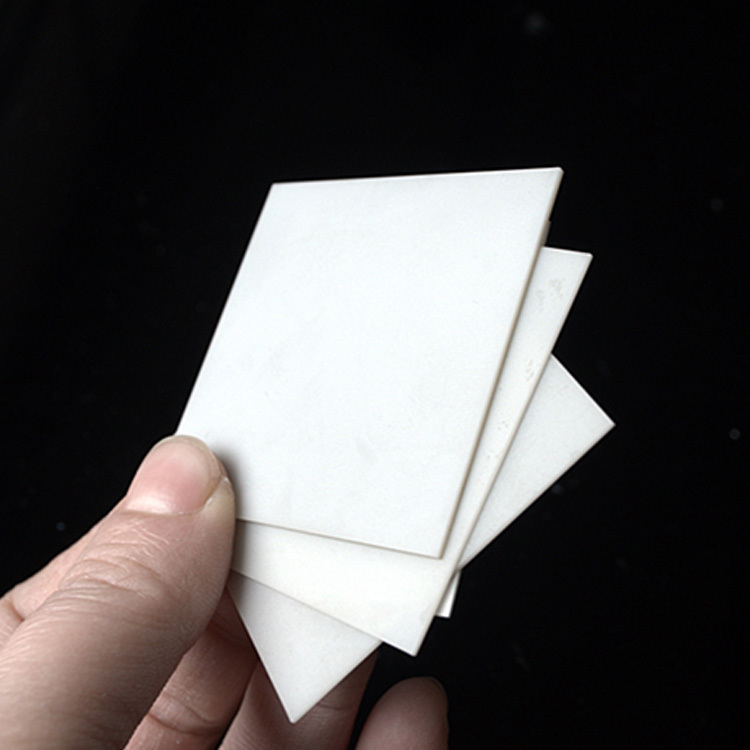

XTL sintyron 170 high thermal conductivity aluminum nitride substrate

aluminum nitride substrates offer a combination of thermal conductivity, electrical insulation, and wide bandgap that make them a versatile choice for a wide range of applications in the electronics and optoelectronics industries. With their excellent thermal properties, high electrical insulation, and wide bandgap, AlN substrates are well-suited for demanding applications that require high performance and reliability.

Contact usProducts Center

XTL sintyron 170 high thermal conductivity aluminum nitride substrate

Brief introduction

Liling Xingtailong Special Ceramics use their own research and development of high quality aluminum nitride

powder as raw material, using casting method to produce aluminum nitride substrate.

This wafer type product can be metallized to make a part of a high thermal conductivity circuit board,

or can be directly used as an insulation sheet after laser cutting.

Class

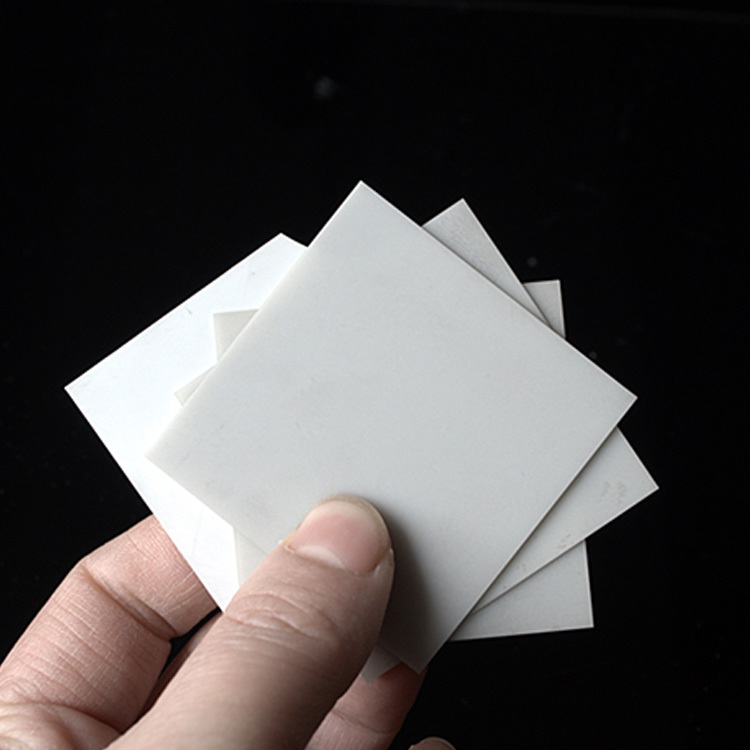

Liling Xingtailong special ceramics provide different surface treatment options to meet the diversified needs of customers

instant burning substrate: the flatness and roughness of the substrate after sintering can meet the technical requirements,

and there is no need to do special treatment.

Abrasive substrate: The substrate is ground after sintering to achieve a higher level of flatness and roughness.

Polished substrate: The surface of the substrate after sintering is polished to achieve a mirror effect.

Product descritption:

One of the key advantages of using aluminum nitride as a substrate material is its high thermal conductivity.

With a thermal conductivity of around 170 W/mK, AlN outperforms traditional substrate materials such as

alumina and silicon carbide, making it an excellent choice for highpower electronic devices that generate a

significant amount of heat. This high thermal conductivity allows for efficient heat dissipation, which is

crucial for the reliability and performance of electronic components.

Performance For Industrial Ceramic

|

Item |

Unit |

Our standard | |

|

Appearance |

Color |

- |

Gray / Beige |

|

|

Microstructure |

- |

Dense and fine grain |

|

|

SurfaceRoughness() |

μm |

0.46 |

|

|

Warpage |

‰ |

<2.5 |

|

Physical |

Water Absorption |

% |

0.061 |

|

|

Vickers Hardness |

GPa |

12 |

|

|

Young Modulus |

GPa |

330 |

|

|

VolumeDensity |

g/Cm3 |

≥3.24 |

|

|

BendingStrength |

[3-point Method]MPa |

>350 |

|

Thermal |

@20℃ThermalConductivity |

[@20℃]W/m·k |

≥170 |

|

|

CoefficientofLinear Expansion |

RT-300℃]10-6mm/℃ |

4.6 |

|

Electrical |

Volume Resistance |

Ω·cm |

1.5×1013 |

|

|

[@1MHz] Dielectric Constant |

- |

10.6 |

|

|

[@1MHz] Dielectric Loss |

- |

4.6×10-4 |

|

|

Dielectric Strength |

(KV/mm) |

≥20 |

Aluminum Nitride Substrate feature:

1.The thermal conductivity of aluminum nitride ceramic substrate is very high, 5 times that of alumina ceramic substrate, the crystal is AIN, strong hardness, good insulation, high temperature resistance and corrosion resistance.

2.The thermal conductivity (thermal conductivity) of aluminum nitride ceramic substrate is greater than or equal to 170W/m.k.,

and the thermal conductivity of aluminum nitride ceramic substrate is that of alumina ceramic substrate and silicon nitride ceramic substrate.

3.Aluminum nitride ceramic substrate without FR4 plate can be very long and large, the size is relatively small, the maximum size of the general aluminum nitride ceramic substrate material is 110mm*140mm, aluminum nitride ceramic substrate is a ceramic base, easy to break, do too big too long does not meet the characteristics of the substrate.

4.Aluminum nitride ceramic substrate dielectric loss is very low, in 0.0002, coupled with the coefficient of thermal expansion is also very low (4.6~5.2), dielectric loss is small, energy consumption is small, high temperature corrosion resistance, durable.

5.The dielectric constant of aluminum nitride ceramic substrate is generally 9.0, which is 0... 8, low dielectric constant, means better quality.

6.Flexural strength refers to the ability of a material to resist bending without breaking, which is mainly used to investigate the strength of brittle materials such as ceramics. The bending strength of the aluminum nitride ceramic substrate is 450Mpa, and the bending strength of the alumina ceramic substrate is 400Mpa, which means that the aluminum nitride ceramic substrate can withstand more pressure and tension.

7.The ability of a material to resist other hard objects pressing into it and causing dented deformation. Commonly used hardness units are Brinell hardness (HB or BHN), Vickers hardness (Hv or VHN), Rockwell hardness (HRA, HRC or RHN) and Knower hardness (HK or KHN). The surface hardness of a material is the result of its strength, proportional limit, toughness, ductility, abrasion resistance, cutting resistance and other properties. The fracture toughness of aluminum nitride ceramic substrate is 3.0Mpa m1/2.

8.Aluminum nitride ceramic substrate is brittle, although the hardness is stronger than the alumina ceramic substrate, the alumina ceramic substrate is white, and the aluminum nitride ceramic substrate is grayish white. The surface roughness of aluminum nitride ceramic substrate is generally required to be less than 10 N.

Advantages of aluminum nitride ceramic parts

Aluminum nitride ceramic parts have high thermal conductivity and electrical insulation, so they can be used in a variety of electronic devices.

The thermal conductivity of aluminum nitride is 170W/(mk), which is 5-8 times that of alumina ceramics. Therefore, AlN ceramics have good thermal shock resistance and can be used in a high temperature environment of 2200 ° C.

Aluminum nitride ceramics is one of advanced precision ceramic materials, which is widely used in electronics industry because of its excellent thermal conductivity and electrical insulation properties. For example:

1.Heat sinks and fins;

2.Laser electrical insulator;

3.Chuck of semiconductor processing equipment, clamping ring;

4.Silicon wafer processing;

5.Substrates and insulators for microelectronic and optoelectronic devices;

6.Electronic packaging substrate;

7.Chip carrier for sensors and detectors.

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.