PRODUCT CENTER

XING TAL LONG

Recommended Products

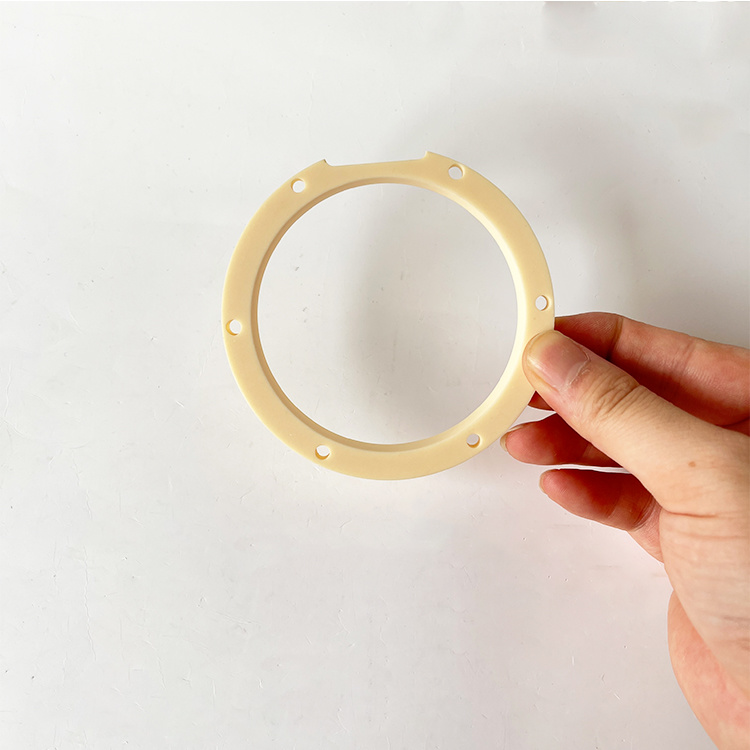

XTL sintyron 99% alumina ceramic gasket ring with hole

99% alumina ceramic gasket ring is a versatile and reliable sealing component that offers superior performance in high-temperature, corrosive, and demanding environments. Its exceptional thermal and chemical resistance, combined with its durability and precision manufacturing, make it an essential component for a wide range of industrial and aerospace applications.

Contact usProducts Center

XTL sintyron 99% alumina ceramic gasket ring with hole

The 99% alumina ceramic gasket ring is a high-quality, durable sealing component made from premium alumina ceramic material. With a purity level of 99%, this gasket ring offers exceptional strength and heat resistance, making it ideal for high-temperature applications where traditional gaskets may fail.

The 99% alumina ceramic gasket ring is designed to provide a reliable seal in demanding environments, such as those found in industrial and aerospace applications. Its superior thermal properties make it capable of withstanding extreme temperatures without compromising its integrity, ensuring a tight and leak-free seal for extended periods of time.

In addition to its impressive thermal resistance, the 99% alumina ceramic gasket ring also boasts excellent chemical resistance, making it suitable for use in corrosive environments where other materials may degrade. Its high hardness and wear resistance further enhance its durability, ensuring long-lasting performance in even the most challenging conditions.

The precision machining of the 99% alumina ceramic gasket ring ensures a tight fit and reliable sealing capability, making it a preferred choice for critical applications where performance and reliability are paramount. Its smooth surface finish prevents leakage and minimizes friction, resulting in a highly efficient and effective sealing solution.

Physical characteristics:

| Test item | alumina | |||

| index | unit | AL997 | AL99 | AL95 |

| Principal component content | N/A | 99.70% | 99% | 95% |

| Color | N/A | ivory white | ivory yellow | White |

| Gas permeability | N/A | airtight | airtight | airtight |

| density | g/cm3 | 3.9 | 3.8 | 3.7 |

| hardness | Moh's hardness | 9 | 9 | 8.8 |

| Water Absorption | N/A | ≤0.2 | ≤0.2 | ≤0.2 |

| Bending strength (20°C) | Mpa | 375 | 340 | 304 |

| Compressive Strength (20°C) | Mpa | 2300 | 2210 | 1910 |

| Coefficient of thermal expansion (25°C to 800° C) | 10X6/° C | 7.6 | 7.6 | 7.6 |

| Insulation strength (5mm thickness) | AC-kv/mm | 10 | 10 | 10 |

| Dielectric loss 25°C lMHz | N/A | v0.0001 | 0.0006 | 0.0004 |

| dielectric constant 25°C MHz | N/A | 9.8 | 9.5 | 9.2 |

| Volume resistivity (20°C) (300°C) (500 °C) | Ω.cm3 | >1014 | >1014 | >1014 |

| 2X1012 | 4X10" | 2X10" | ||

| N/A | N/A | N/A | ||

| Long-term service temperature | ℃ | 1700 | 1600 | 1400 |

| Thermal conductivity (25° C) | W/m/K | 35 | 34 | 20 |

Alumina Ceramic ring Information:

| Product | alumina ceramic ring |

| Material | alumina |

| Purity | 99% |

| Color | light yellow |

| Shape | Round |

| Density | 3.5g/cm3 |

Feature of alumina ceramics:

1) High temperature resistance: alumina ceramic sealing ring can show excellent stability in high temperature environment, can withstand high temperature and thermal cycle, and is not easy to deformation and rupture.

2) Corrosion resistance: Due to its good chemical stability and inert surface, alumina ceramic sealing rings can resist corrosion and oxidation, so that it can maintain stable performance in a variety of corrosive media.

3) High hardness: alumina ceramic sealing ring has high hardness, maintain stable shape and sealing performance under vibration and high pressure environment, and has good wear resistance.

4) Insulation: alumina ceramic sealing ring is an excellent insulating material, which can maintain good insulation performance under high pressure environment and effectively isolate the conduction of electric and thermal fields.

5) Low coefficient of thermal expansion: The thermal expansion coefficient of alumina ceramic sealing ring is low to adapt to the thermal expansion and contraction under high temperature conditions, reducing the stress and damage caused by temperature changes.

Advantages of alumina ceramics:

1.Dimensional and thermal stability, high performance characteristics, hydrolysis resistance, self-lubrication, extended service life, reduced downtime and cost, low moisture content, noise reduction

Application of alumina ceramic ring:

Alumina ceramic sealing rings are widely used, and the following is the introduction of its main application scenarios:

1) Aerospace field: In aerospace equipment, alumina ceramic sealing rings can be used for sealing and insulation in engines and gas turbines, which can withstand high temperature and high pressure environments to ensure the normal operation of equipment.

2) Chemical field: alumina ceramic sealing ring can be used in chemical equipment for the sealing of high-temperature reaction vessels and pipelines, effectively isolating the leakage of harmful gases and liquids, and ensuring process safety and environmental protection.

3) Power field: In power equipment, alumina ceramic sealing rings are often used for the insulation and sealing of generator sets and transformers to improve the safety and stability of equipment and extend the service life.

4) Petrochemical field: alumina ceramic sealing ring can be used for the sealing of oil refining units and chemical reactors, which can withstand the erosion of high temperature and corrosive media to ensure the normal operation of equipment and product quality.

Company Information:

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service.Just send us your drawing if you have it.If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity.We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.