PRODUCT CENTER

XING TAL LONG

Recommended Products

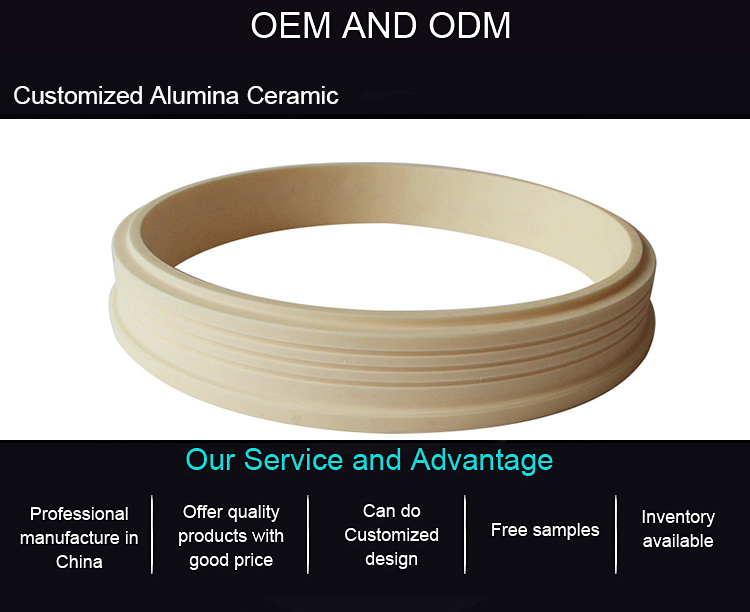

XTL sintyron high quality big size alumina ceramic corrugated ring

Alumina ceramic corrugated rings are a versatile and reliable packing material for separation and purification processes in various industries. Their high heat and chemical resistance, as well as their excellent mechanical strength, make them a preferred choice for demanding applications. With their efficient mass transfer capabilities and easy installation, alumina ceramic corrugated rings are an essential component in many industrial processes.

Contact usProducts Center

XTL sintyron high quality big size alumina ceramic corrugated ring

Product description:

Material Introduction:

|

√ High Voltage Insulator |

√ High Purity, Max. 99.8% |

√ Various Available Grades |

|

√ Hard and Wear Resistant |

√ High Corrosion Resistance |

√ High Mechanical Strength |

|

√ Good Thermal Conductivity |

√ High Operating Temperature |

√ Most Favorable Fine Ceramic |

Specification :

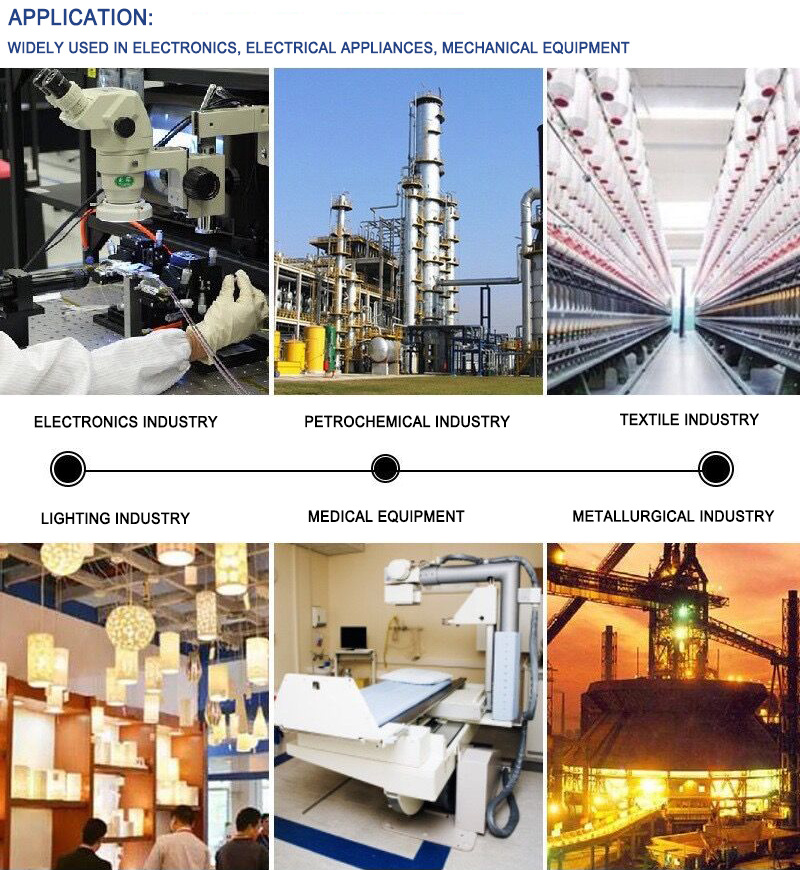

Alumina ceramic corrugated ring is a type of structured packing material used in various industrial applications for separation and purification processes. This type of packing material is made from high-quality alumina ceramic, which offers excellent heat and chemical resistance, making it ideal for use in harsh environments.

The corrugated ring design provides a large surface area for contact between the gas and liquid phases, allowing for efficient mass transfer and separation. The unique shape of the rings creates turbulence and promotes mixing of the phases, enhancing the overall efficiency of the separation process.

One of the key advantages of alumina ceramic corrugated rings is their high mechanical strength and durability. They can withstand high temperatures and aggressive chemicals without degrading, making them suitable for use in a wide range of industrial applications.

Alumina ceramic corrugated rings are commonly used in distillation, absorption, and stripping columns in industries such as petrochemical, chemical, and pharmaceutical. They are also used in environmental applications for air and water treatment processes.

The installation of alumina ceramic corrugated rings is simple and straightforward, as they can be easily stacked inside a column or vessel. They can be used as random packing or structured packing, depending on the specific requirements of the application.

| Composition | AL95 | AL99 |

|

Color |

White | Ivory |

|

Density (g/cm3 ) |

3.72 |

3.85 |

|

Thermal conductivity (W/m. K) |

22.3 |

32 Kpsi |

|

Thermal Expansion (x10-6 /℃) |

8 | 8.2 |

|

Dielectric Constant (at 1MHZ) |

9.5 | 9.8 |

|

Loss Tangent (x10-4 at 1MHZ) |

3 | 2 |

|

Volume Resistivity (ohm-m) |

>1014 |

>1014 |

|

Flexural Strength (N/mm2 ) |

350 |

500 |

Alumina ceramic parts are known for their high hardness, wear resistance, and thermal stability, making them ideal for use in harsh operating conditions. They also have a low coefficient of thermal expansion, which helps to minimize the risk of cracking or deformation when exposed to temperature fluctuations. In addition, alumina ceramic parts have excellent electrical insulation properties, making them suitable for use in high voltage applications. They are also chemically inert and resistant to corrosion, making them a durable and long-lasting option for demanding environments. Overall, alumina ceramic parts are a versatile and reliable choice for a wide range of industrial applications, thanks to their superior mechanical and thermal properties.

Feature

1.good thermal conductivity

2.excellent electrical insulation

3.corrosion & erosion resistant

4.thermal shock resistant

5.high working temperature

6.low thermal expansion

7.very hard, wear resistant

8.high mechanical strength

9.flexible custom production

Company Information: