PRODUCT CENTER

XING TAL LONG

Recommended Products

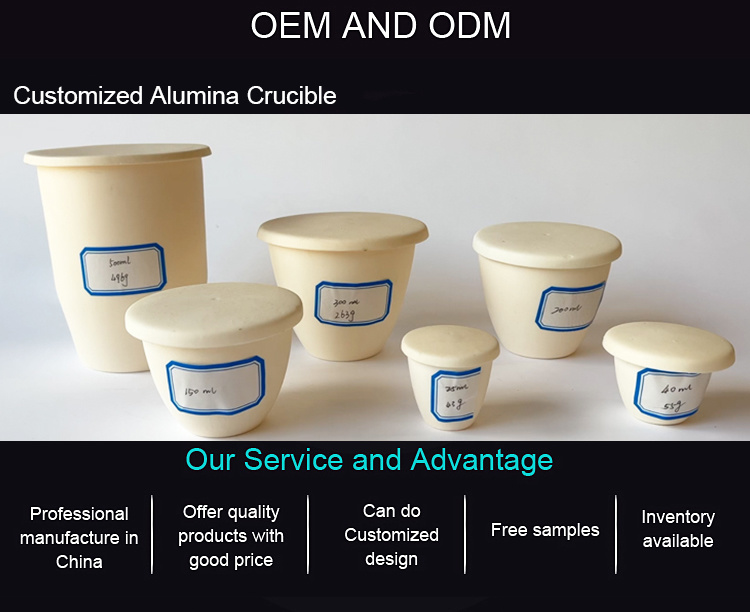

XTL sintyron manufacturer customized cylindrical melting alumina ceramic crucible

Alumina ceramic crucibles are versatile and durable tools that can withstand high temperatures and harsh chemical environments. By following the steps outlined above, you can effectively use alumina ceramic crucibles for various heating, melting, and casting applications with confidence in their performance and reliability.

Contact usProducts Center

XTL sintyron manufacturer customized cylindrical melting alumina ceramic crucible

Alumina ceramic crucibles are commonly used in laboratories and industrial settings for melting, casting, and heating various materials. These crucibles are known for their high thermal conductivity, chemical resistance, and thermal shock resistance. Here is a step-by-step guide on how to use alumina ceramic crucibles:

1. Choose the right size crucible for your application. Alumina ceramic crucibles come in different sizes and shapes, so make sure to select the one that best fits your needs.

2. Prepare the materials you want to heat or melt in the crucible. Ensure that the materials are clean and free from any contaminants that could affect the purity of the final product.

3. Place the alumina ceramic crucible in a furnace or kiln that is capable of reaching the desired temperature. Alumina ceramic crucibles have a high thermal resistance, typically up to 1600°C, so make sure your furnace can reach and maintain the necessary temperature.

4. Carefully place the materials into the crucible using appropriate tools such as tongs or gloves to prevent burns. Avoid overfilling the crucible to prevent spills and ensure uniform heating of the materials.

5. Close the furnace or kiln door and allow the materials to heat up gradually. Alumina ceramic crucibles have a low thermal expansion coefficient, which helps prevent cracking or shattering due to sudden temperature changes.

6. Monitor the temperature of the furnace or kiln to ensure it reaches the desired level for the materials to melt or react properly. Alumina ceramic crucibles can withstand high temperatures for extended periods, making them ideal for various applications.

7. Once the materials have reached the desired temperature and undergone the necessary processes, carefully remove the alumina ceramic crucible from the furnace using appropriate safety equipment. Allow the crucible to cool down slowly to prevent thermal shock.

8. Clean the alumina ceramic crucible thoroughly after use to remove any residues or contaminants that may affect future experiments or processes. Use mild detergents and non-abrasive tools to avoid damaging the crucible's surface.

Alumina Crucible Information

| Product | Alumina Crucible |

| Material | Al2O3 |

| Purity | 99%, 99.3%, 99.5% |

| Color | White/Ivory |

| Shape | Arc/Square/Rectangle/Cylinder/Boat |

| Capacity | 1-2000 ml |

| Density | 3.98 g/cm3 |

| Melting Point | 2020℃ |

| Max. Working Temperature | 1800 ℃or 3180 F |

Further, these can also be custom made on request.

Alumina Crucible Cylinder Type

| Regular size +- mm | |||

| Capacity (ml) | Top dia (mm) | Bottom dia (mm) | Height(mm) |

| 3ml | 20mm | 16mm | 17mm |

| 4ml | 25mm | 19mm | 18mm |

| 5ml | 26mm | 18mm | 21mm |

| 10ml | 30mm | 20mm | 28mm |

| 15ml | 35mm | 21mm | 30mm |

| 20ml | 38mm | 24mm | 35mm |

| 25ml | 40mm | 25mm | 35mm |

| 30ml | 45mm | 27mm | 39mm |

| 40ml | 47mm | 28mm | 43mm |

| 50ml | 50mm | 30mm | 48mm |

| 100ml | 61mm | 31mm | 60mm |

| 150ml | 73mm | 43mm | 67mm |

| 200ml | 82mm | 43mm | 70mm |

| 300ml | 88mm | 53mm | 85mm |

| 500ml | 108mm | 62mm | 108mm |

| 800ml | 113mm | 62mm | 140mm |

Performance For Industrial Ceramic

|

Item |

|

|

|

|

Al2O3 Content(%) |

99 |

|

Physical Characteristics |

Heat resistance(℃) |

1800 |

|

Bulk density(g/cm3) |

3.9 |

|

|

Water absorption(%) |

0 |

|

| Flexural strength(Mpa) |

360 |

|

|

Mechanical Characteristics |

Hardness vickers (Gpa) |

15.6 |

|

Elastic modulus (Gpa) |

370 |

|

|

Poisson’s ratio |

0.23 |

|

|

Thermal Characteristics |

Linear expansion coefficient(20℃-500℃) 10-6/℃ |

8 |

|

Thermal conductivity w/(m.k) |

32 |

|

|

Specific Heat *10-3J/(kg*K) |

0.9 |

|

|

Electrical Characteristics |

Dielectric constant (1MHZ) |

9.9 |

|

Dielectric loss angle *10-4 |

1 |

|

|

Dielectric strength *106V/m |

15 |

Application

Used for testing laboratory and a variety of industrial analysis.

Related Products

Company Information

FAQ

Why us?

* Professional manufacturer since 1997.

* Strict quality control on production process and tolerance.

* Free samples available

* Customized production based on your drawing or specification

* On-time delivery and reliable support and service

* Inventory available for quick shipment

* We keep confidentiality of all the drawings and business information between us.

Are you a trading company or a manufacturer?

* We are a manufaturer.

Can you provide the free samples?

* Yes,we can offer free sample if we have it in stock,but the courier fee is to be collected.

Do you accept customized production based our specification?

* Yes,we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, we will work out the drawing for you.

What's the delivery time?

* 7 working days for standard products 30 days for customized products.

What is the MOQ?

* No limit to the quantity. We can offer the best proposal and solutions according to your condition.

What is the payment terms you accept?

* T/T,LC,Western Union,moneygram are acceptable.

How to deal with the faulty?

* Firstly, Our product are produced in strict quality control system and the defective rate will be less than 2%.

If there are problems with the product, we will provide free replacement.